Chrome Plated Steel, also known as Tin Free Steel (TFS), is a cold-rolled low-carbon steel sheet with a surface coating of metallic chromium and chromium hydroxide oxide. Characterized by high hardness, corrosion resistance, high gloss, and excellent coating adhesion, it is widely used in food contact materials, chemical containers, electronic enclosures, and decorative building materials.

Chromium-Plated Steel Structure

Steel Base Plate: Provides structural support.

Metal Chromium Layer: Core functional layer, imparts high hardness and corrosion resistance.

Hydrated Chromium Oxide Layer: Enhances oxide film stability.

Oil Film: Further protects the surface and reduces friction.

Material of Chrome Plated Steel

MR Type: Non-metallic inclusion controlled steel, suitable for general stamping forming. Applicable for food can heads and bottoms, beverage can lids, and three-piece can bodies produced via adhesive bonding.

L Type: Ultra-low carbon and nitrogen steel, suitable for ultra-deep drawing with excellent aging resistance. Applicable for draw-reel drums (DRD drums) or complex-shaped chemical containers.

D Type: Aluminum-killed steel with high strength, suitable for containers requiring high strength. Used for producing high-pressure-resistant can bottoms and lids.

TH Type: Phosphorus-hardened steel offering high strength and lightweight properties. Used for manufacturing the ring portion of easy-open lids.

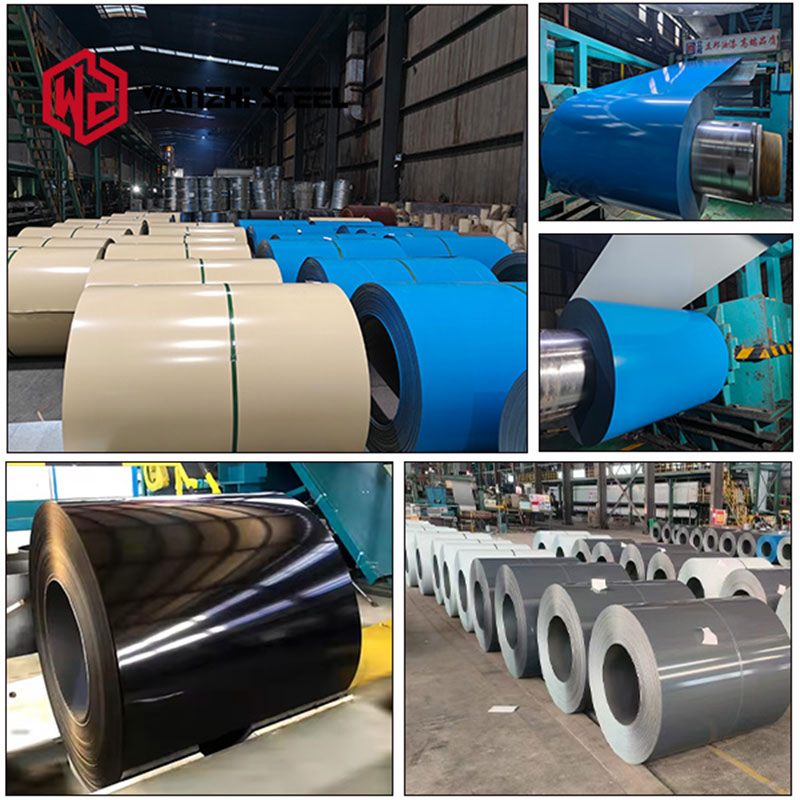

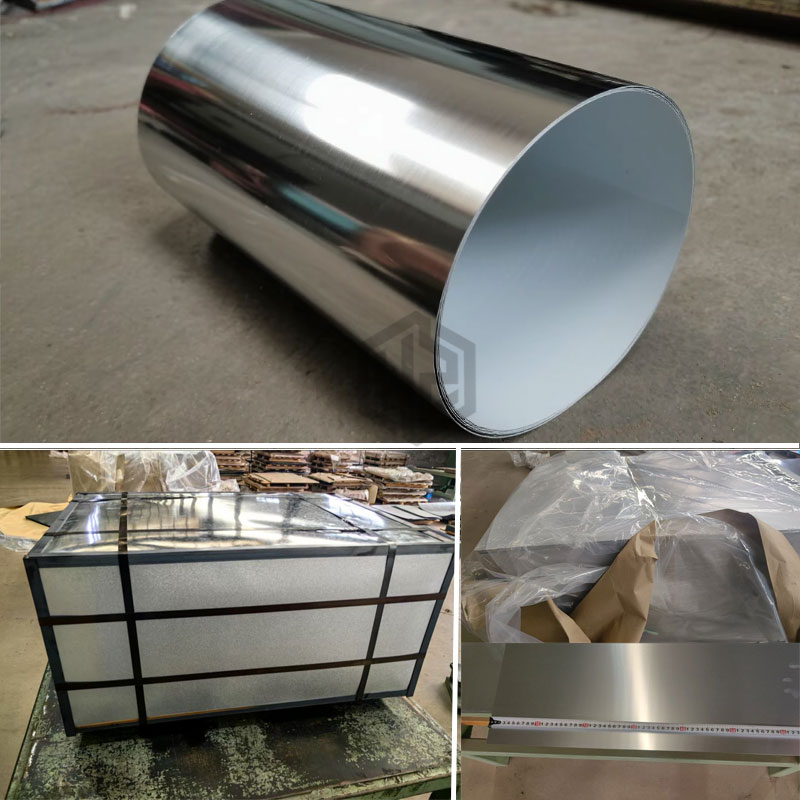

Surface of Chrome Plated Steel

Bright Surface (Code: BA): Mirror-smooth finish with high reflectivity for an elegant appearance.

Matte Surface (Code: MT): Uniform non-reflective surface suitable for printing and coating.

Stone Texture Surface (Code: ST): Features subtle grain patterns enhancing tactile and visual appeal.

Silver Surface (Code: SL): Characteristic chrome-plated appearance with a silver-gray hue and modern texture.

Chromium Plating Quantity Code

| Type | Chromium Metal Layer (mg/m²) | Hydrated Chromium Oxide Layer (mg/m²) |

| Standard | 100–150 | 10–20 |

| High-Chromium | 150–200 | 20–30 |

| Low-Chromium | 70–100 | 5–10 |

Tempering Degree Code

| Temper Grade | Characteristics |

| T-1, T-2 | Soft, with better ductility and excellent formability |

| T-3 | Standard hardness, with a balance between formability and strength |

| T-4, T-5 | Hard, with high strength |

Advantages and Applications of Chrome-Plated Steel

Chrome-plated steel serves as a more economical alternative to tinned steel. Both are high-quality low-carbon cold-rolled thin steel sheets sharing identical steel grades, tempering systems (T-value), and dimensional specifications. Chrome-plated steel offers lower costs and superior coating adhesion, making it a more cost-effective choice for applications where cost sensitivity or high decorative requirements are paramount.

Advantages

- Cost-effectiveness: Significantly lower cost compared to tin-plated steel, delivering outstanding value for money.

- High Hardness: Chromium coating hardness ranges from 400HV to 1200HV.

- Wear Resistance: Significantly reduces friction and wear, extending service life by 3-5 times compared to standard steel.

- Corrosion Resistance: Chromium layers rapidly form a dense oxide film (Cr₂O₃) in air, providing barrier protection for the substrate.

- Functional versatility: Customizable coating properties by adjusting process parameters (e.g., current density, temperature).

- Coating adhesion: Exceptionally receptive to spraying and printing, ensuring durable, non-peeling paint films.

- Aesthetic appeal: High gloss finish suitable for decorative applications.

- Environmental sustainability: 100% recyclable.

Applications

- Textile machinery

- Automotive components

- Outer shells and inner liners

- Kitchenware

- Medical devices

- Chemical packaging

- Architectural finishes

- Electronics and appliances

Custom Chrome-Plated Steel

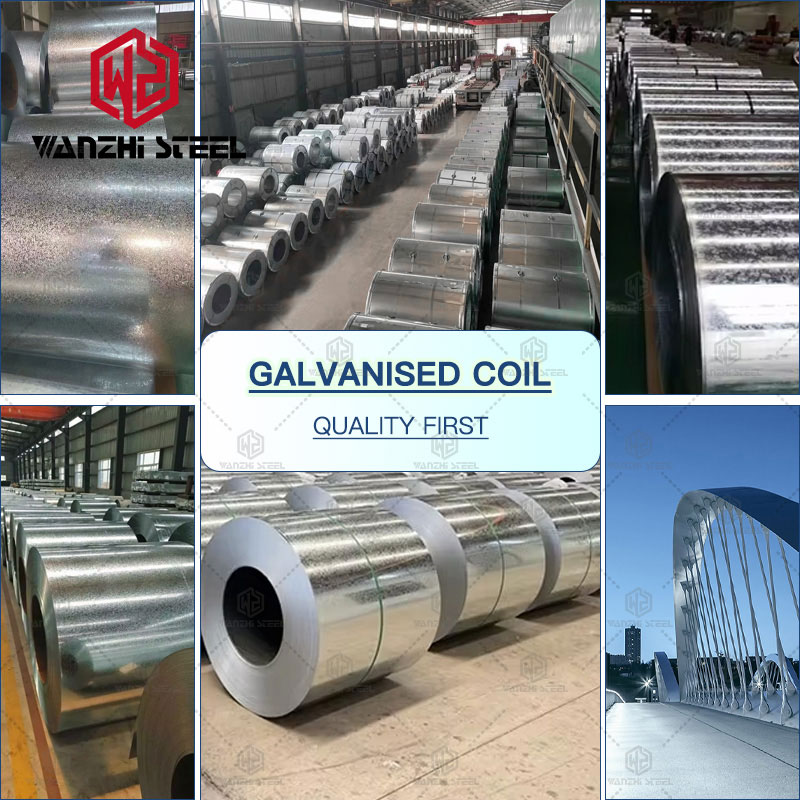

Wanzhi Group‘s factory in Boxing County, Binzhou City, Shandong Province, China, features advanced chrome plating production lines, laboratories, and sample rooms. We provide Chrome Plated Steel OEM and ODM services, supporting customization in substrate selection, coating thickness, mechanical properties, dimensional specifications, and surface treatments.

Facility

Equipped with multiple continuous chrome plating lines and testing equipment including spectrometers, coating thickness gauges, and salt spray chambers. Delivery time ranges from 5–40 business days with a minimum order quantity of one coil. Limited stock available.

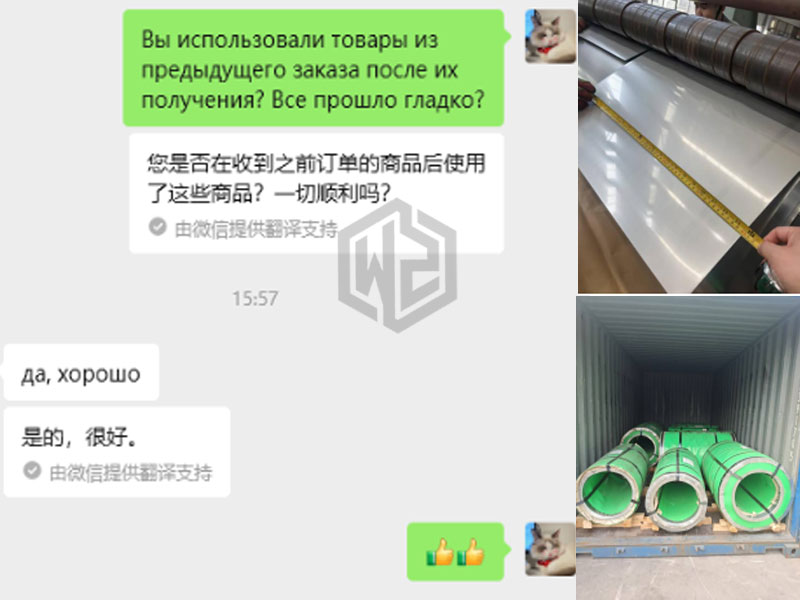

Customer Feedback

We maintain long-term partnerships with numerous domestic and international food, electronics, and construction material enterprises. Our consistent product quality and responsive service have earned strong customer trust.

If you seek cost-effective metal packaging or structural materials with superior coating properties, Chrome Plated Steel is the ideal choice. Contact us today for complimentary samples and a quote!