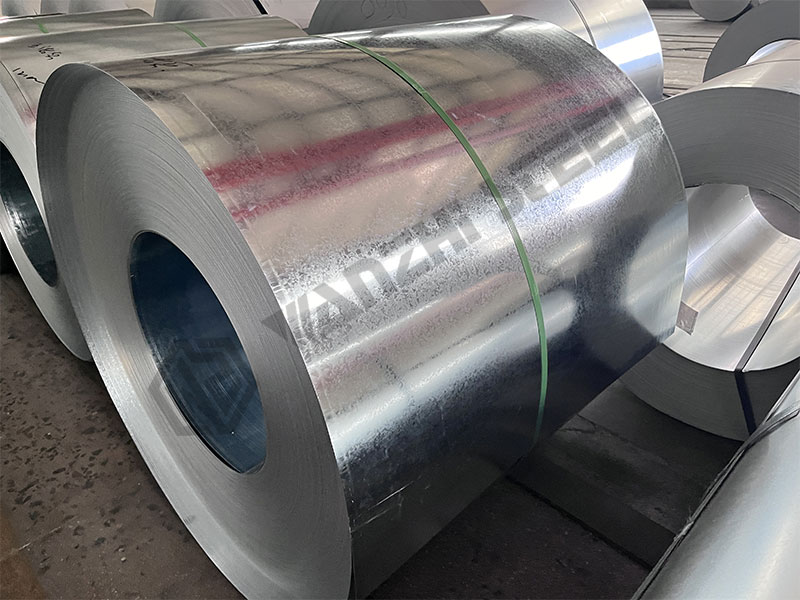

Cold rolled galvanized steel is a ferrous metal material produced through cold rolling and hot-dip galvanizing. It combines the strength and formability of cold-rolled steel with the corrosion resistance of the zinc coating. Commonly sold in coil, sheet, and strip forms, it serves as a fundamental material widely used in industrial and construction applications.

Cold Rolled Galvanized Steel for Sale

Wanzhi Group is a Chinese supplier of color coated and galvanized steel, producing and selling various raw materials and finished products including cold-rolled galvanized steel, hot-rolled galvanized steel, painted galvanized steel, and more. We also provide additional services such as leveling, slitting, bending, stamping, and forming. We provide OEM and ODM services for galvanized steel applications across diverse industries.

Specifications

| Dimension | Common Range |

| Base Material Thickness | 0.15mm – 6.0mm |

| Width | 600mm – 1250mm |

| Length | Coils or Cut-to-Size Sheets |

| Zinc Coating Weight | Z30 – Z350 |

| Surface Treatment | Regular Zinc Flower, Small Zinc Flower, No Zinc Flower, Phosphating, Oiled |

Grade

| Standard | Grade Example | Performance and Applications |

| European Standard (EN) | DX51D | Most commonly used. Low carbon steel base, excellent formability, used for deep drawing, bending, etc. |

| DX52D, DX53D | Better anti-aging stability, used for higher forming processing requirements. | |

| S220GD, S350GD | Structural grade. Used for components requiring higher strength, such as beams, columns, and load-bearing structures. | |

| Chinese Standard (GB/T) | DC51D | Corresponds to EN’s DX51D, cold-rolled low carbon steel sheet for stamping. |

| DC52D, DC53D | Corresponds to DX52D, DX53D. | |

| S250GD, S350GD | Corresponds to EN’s structural grades. | |

| American Standard (ASTM) | A653 | Common grades include CS Type B (commercial grade), FS Type B (forming grade), SS Grade 33 (structural grade). |

Property

| Property | Description |

| Corrosion Resistance | Core performance. Directly determined by the zinc coating weight. In standard atmospheric conditions, Z275 lasts far longer than Z90. The “sacrificial anode” protection of zinc also protects areas like cuts and scratches. |

| Formability | Determined by the base material performance. Most cold-rolled galvanized steel can undergo cutting, stamping, bending, and rolling forming (roof tile pressing), among other processes. |

| Coating Property | Surface can serve as a substrate for color-coated sheets (PPGI/PPGL), with good paint adhesion. |

| Weldability | Can undergo welding operations like spot welding. |

| Strength | Structural-grade materials have high yield strength and tensile strength, capable of bearing larger loads. |

Price

Cold-rolled galvanized steel price: 600-800 USD per ton. Factors affecting galvanized steel pricing include grade, thickness, zinc coating, surface finish requirements, and more. Leave us a message with your requirements to get a free quote!

Cold Rolled Galvanized Steel Process

Cold rolled galvanized steel utilizes high-quality cold-rolled steel coil as the substrate, coated with a dense zinc layer. It offers excellent strength, formability, corrosion resistance, and decorative properties, making it widely used in construction, interior decoration, industrial production, and other fields.

Processing

- Process: Cold-rolled steel is immersed in molten zinc (approximately 450-460°C), causing a metallurgical reaction between zinc and the steel surface to form a zinc-iron alloy layer.

- Characteristics: Thick coating, strong adhesion, excellent corrosion resistance.

- Process: Zinc ions are deposited onto the cold-rolled steel surface through electrolysis, forming a uniform zinc layer.

- Characteristics: Thin coating, smooth surface, excellent workability.

Characteristics

- Corrosion Resistance: In humid or salt-fog environments, the zinc layer corrodes preferentially, extending the service life of the cold-rolled steel.

- Processability: Retains the strength, toughness, and machinability of cold-rolled steel.

- Appearance & Aesthetics: Features a silver-gray metallic finish that is both visually appealing and durable, with further enhancement possible through painting.

- Environmental Considerations:

- Cost-Effectiveness: Offers a highly economical rust-proof solution compared to other corrosion-resistant metals like stainless steel.

- Environmentally Friendly: The galvanizing process meets environmental standards. Zinc is recyclable, and the zinc coating prevents heavy metal pollution caused by steel corrosion.

Applications

- Construction Industry: Roofing, walls, partitions, door/window frames, steel bridges, ventilation ducts, etc.

- Automotive Industry: Manufacturing vehicle bodies, chassis, exhaust pipes, and other components.

- Home Appliance Manufacturing: Outer casings for refrigerators, washing machines, air conditioners, etc.

- Agriculture & Infrastructure: Construction of grain silos, water troughs, guardrails, traffic signs, etc.

- Energy Sector: Used in solar panel mounts, wind turbine towers, etc.

- Advanced Processing: Galvanized sandwich panels, galvanized doors,GI purlins, pre-painted galvanized steel coil (PPGI), etc.

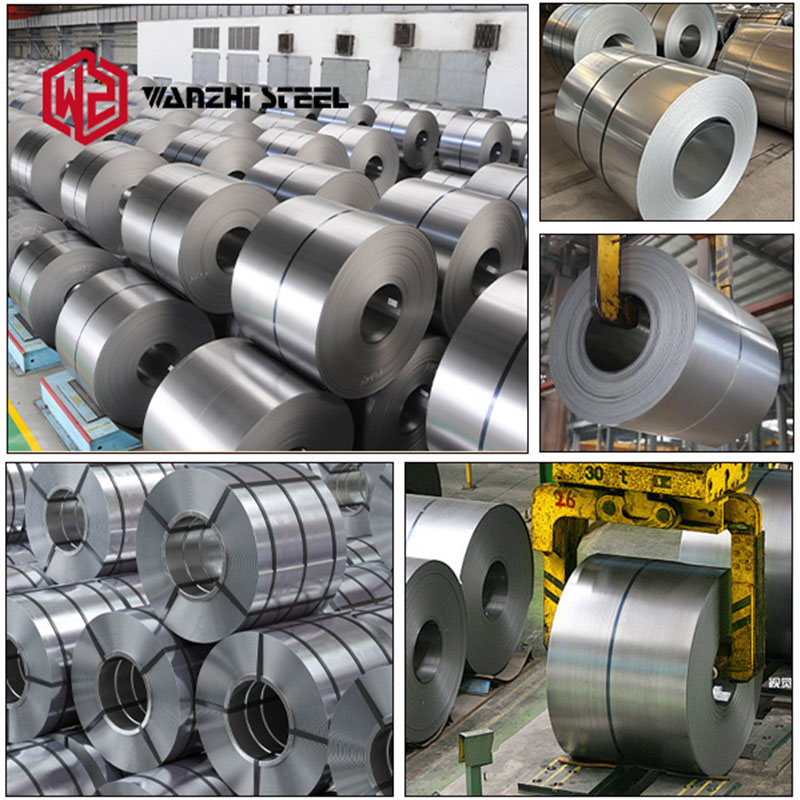

Cold Rolled Galvanized Steel Factory

If you are seeking a cold-rolled galvanized steel factory supplier, Wanzhi Group looks forward to collaborating with you! We possess our own factory, galvanizing production lines, finished product processing lines, extensive export experience, and solution customization capabilities.

Supplier

As a professional galvanized steel supplier, Wanzhi Group not only manufactures and produces a full range of galvanized products but also provides tailored solutions based on your specific application requirements. Our factory holds ISO9001 Quality Management System and ISO14001 Environmental Management System certifications. Products comply with international standards including Chinese National Standards (GB), European Standards (EN), and American Standards (ASTM). Our solutions span multiple sectors in construction and industrial production.

Production Lines

We operate 7 coating and galvanizing production lines, slitting lines (cutting wide coils to required widths), and roll forming equipment (shaping galvanized steel coils into roofing panels, wall panels, etc.). With an annual capacity of 600,000 tons, we maintain stable raw material supply and large-scale delivery capabilities.

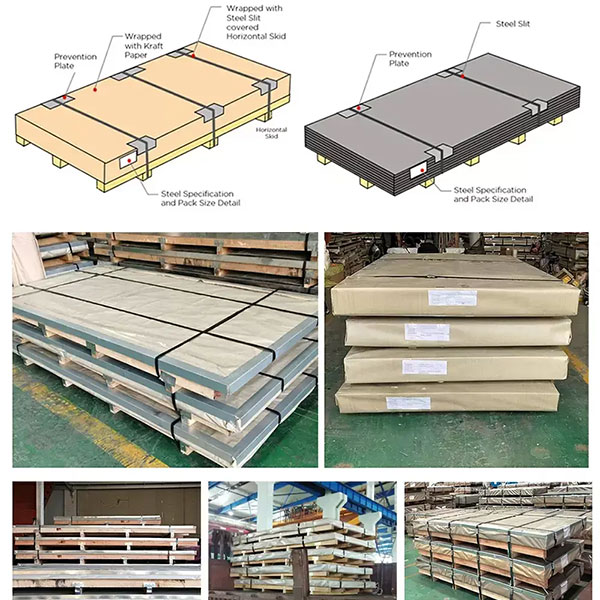

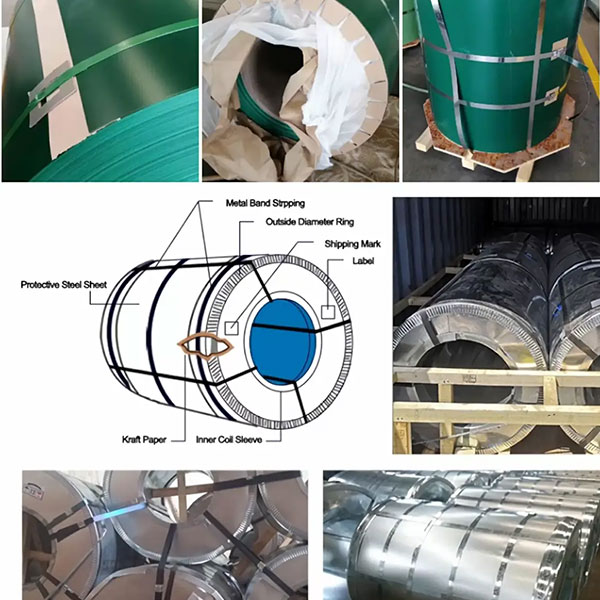

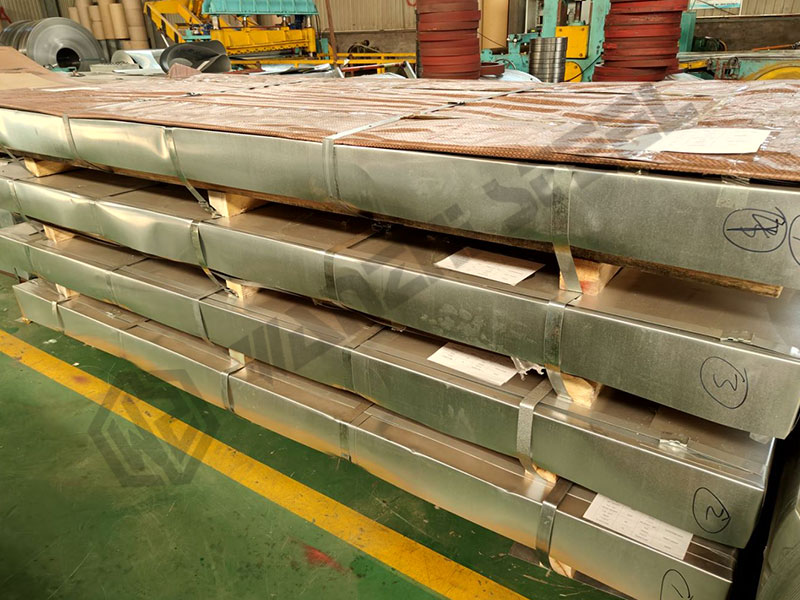

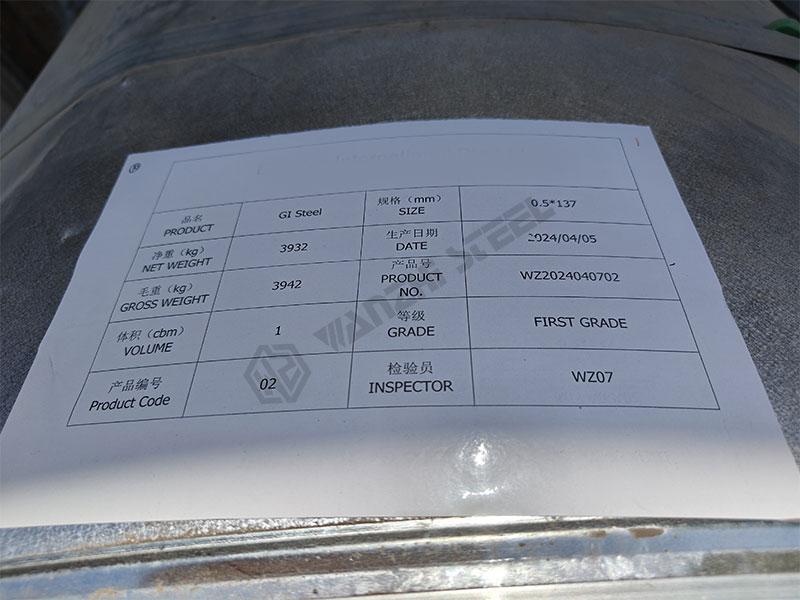

Packaging

White rust on galvanized steel surfaces results from moisture exposure. Professional packaging is crucial for protecting products during long-distance transport and storage. Wanzhi Group’s steel coils and sheets adhere to international export standards, utilizing moisture-proof paper, plastic film, galvanized iron sheets, and steel strapping. Upon request, waterproof plastic woven fabric and wooden pallet securing are also available.

Case

Wanzhi Group’s cold-rolled galvanized steel coils and sheets, along with cold-rolled pre-painted galvanized steel coils and sheets, have been exported to over 100 countries and regions worldwide, including Turkey, Turkmenistan, Saudi Arabia, the United Arab Emirates, Peru, Colombia, and more.

Wanzhi Steel Factory integrates multiple production lines including cold rolling, galvanizing, and color coating, offering one-stop solutions from raw materials to finished products. If you are seeking premium cold rolled galvanized steel, please feel free to contact us.