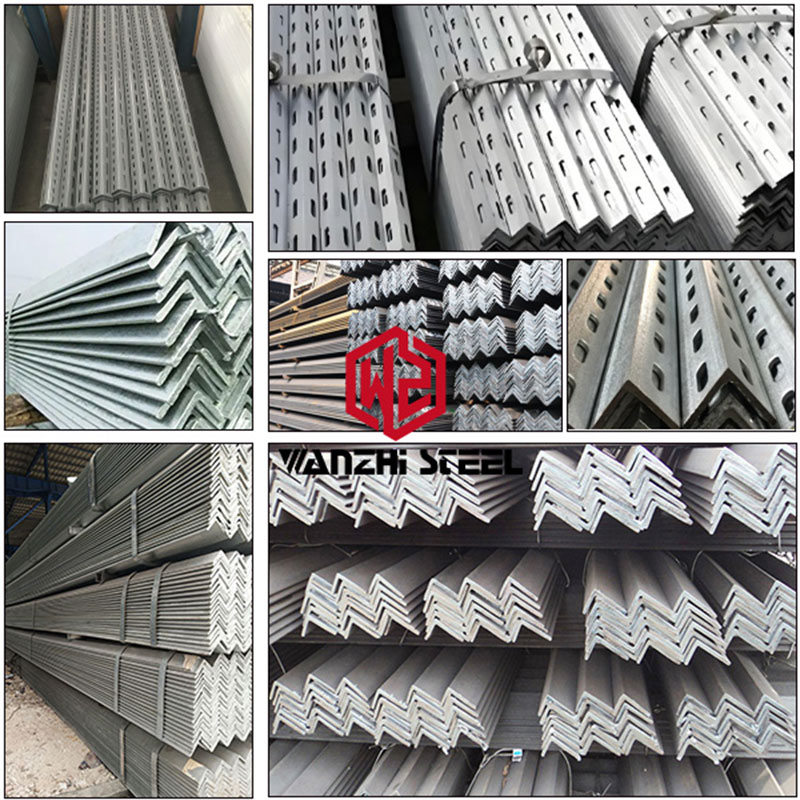

Galvanized Angles are one of the popular galvanized steel structural products, offering the dual functions of structural load-bearing and long-term corrosion resistance. Widely used in building steel structures, bridge supports, equipment frames, and municipal engineering, Wanzhi Group, as a professional steel supplier, produces and sells various types of basic components, including equal-leg angles and unequal-leg angles.

Galvanized Angles Specifications

| Main Dimensions (mm) | Leg Width × Leg Width × Thickness | Theoretical Weight (kg/m) | Standard Length (m) |

| Small Angles | 20×20×3 | 0.889 | 6–12 |

| 25×25×3 | 1.124 | 6–12 | |

| 30×30×3 | 1.373 | 6–12 | |

| Medium Angles | 40×40×4 | 2.422 | 6–12 |

| 50×50×5 | 3.770 | 6–12 | |

| 60×60×6 | 5.420 | 6–12 | |

| Large Angles | 75×75×8 | 9.030 | 6–12 |

| 100×100×10 | 15.100 | 6–12 | |

| 125×125×12 | 22.700 | 6–12 |

Classification

Primary Structural Angles

- Specifications: Leg width ≥ ∠75, thickness ≥ 6mm

- Applications: Factory roof trusses, transmission towers, bridge supports

Secondary Structural Angles

- Specifications: Leg width ∠40–∠75, thickness 3–5mm

- Applications: Purlins, bracings, equipment supports

Decorative/Auxiliary Angles

- Specifications: Leg width ∠20–∠40, thickness 2–3mm

- Applications: Door/window frames, guardrails, ceiling keels

Mechanical Properties (Q235B)

| Performance Indicator | Standard Requirement | Wanzhi Typical Value | Test Standard |

| Yield Strength (ReH) | ≥235 MPa | 260–320 MPa | GB/T 228.1 |

| Tensile Strength (Rm) | 370–500 MPa | 410–450 MPa | GB/T 228.1 |

| Elongation (A) | ≥25% | 28–32% | GB/T 228.1 |

| Impact Toughness | ≥27J (20℃) | ≥35J | GB/T 229 |

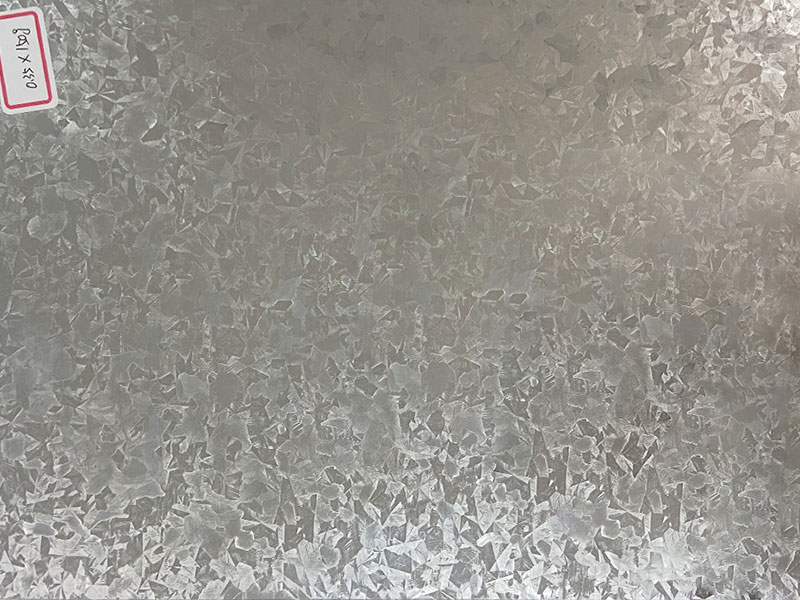

Zinc Coating

Hot-Dip Galvanized (Mainstream Process):

Silver-gray surface, minor spangling allowed. Zinc coating weight ≤600g/m².

Electro galvanized (Light-Duty Scenarios):

Smooth surface with no obvious scratches. Suitable only for indoor dry, non-corrosive environments (e.g., furniture frames).

Galvanized Angles Dimensional Measurement

| Measurement Item | Measuring Tool | Permissible Deviation |

| Leg Width | Caliper / Micrometer | ±1.0mm |

| Thickness | Ultrasonic Thickness Gauge | ±0.3mm |

| Length | Tape Measure / Laser | +50mm / -0mm |

| Straightness | Surface Plate + Feeler Gauge | ≤0.3% of length |

Galvanized Angles Features

Excellent Corrosion Resistance:

- Service life is 3–5 times that of plain carbon steel angles.

- The zinc coating provides both a physical barrier and sacrificial anode protection, offering 15–30 years of corrosion resistance in various environments.

Superior Mechanical Properties:

- The “L-shaped” cross-section provides structural stability, strong load-bearing capacity, and easy assembly.

Aesthetic Appearance:

- Attractive silver-gray finish, high dimensional accuracy, and strong coating adhesion allow direct use in outdoor visible applications.

Galvanized Angles Customization

As a professional steel supplier, Wanzhi Group not only offers galvanized steel and galvanized section steel solutions but also provides full-dimension customization for special projects (e.g., long-span bridges, heavy equipment). Customization covers leg width, thickness, length, and zinc coating according to application needs.

Customization Range

Leg width: Up to ∠400×400×50 for equal-leg angles; up to ∠300×200×40 for unequal-leg angles.

Thickness: Standard 3–24mm; special orders 25–50mm.

Length: Custom lengths from 1–18m (≤6m considered short, >12m considered long).

Zinc coating: Standard hot-dip galvanizing from Z30 to Z350g.

Factory

Location: Xingfu Town, Boxing County, Binzhou City, Shandong Province, China.

Production Lines: Equipped with galvanizing lines, angle steel rolling lines, painting lines, etc.

Quality Control: Certified with ISO9001 and ISO14001 management systems. Products comply with international standards such as GB/T 706, EN 10025, and ASTM A36. Factory laboratory includes material testing machines, impact testers, magnetic coating thickness gauges, salt spray test chambers, etc.

Delivery Capability: Some specifications available from stock. Production lead time ranges from 5 to 45 working days.

Galvanized Angles vs. Plain Carbon Steel Angles

| Comparison | Galvanized Angles | Plain Carbon Steel Angles |

| Corrosion Resistance | Excellent – active zinc layer protection | Poor – relies on passive protection like paint |

| Service Life | 20–50 years (depending on environment) | 5–15 years (requires regular maintenance) |

| Installation Efficiency | High | Low |

| Appearance | Silver-gray, industrial aesthetic | Black, requires painting for aesthetics |

| Environmental Impact | Better – zinc is recyclable | Moderate – paints may cause pollution |

| Suitable Environments | Indoor/outdoor, especially harsh conditions | Dry indoor or short-term outdoor only |

| Mechanical Performance | Base steel strength equal to carbon steel; zinc coating does not affect strength | Base strength same as galvanized, but may drop 30–50% after corrosion |

| Maintenance Cost | Low – inspection every 5 years, no repainting required | High – annual repainting, high labor and material costs |

| Procurement Cost | 30–50% higher than equivalent carbon steel angles (due to galvanizing process) | Lower (only base material cost) |

Wanzhi Galvanized Section Steel Categories

Angles: L-shaped cross-section, provides bi-directional support, simple and stable.

C-Purlins: C-shaped cross-section, lightweight with good bending resistance.

Z-Purlins: Z-shaped cross-section, optimized material distribution, high section modulus.

Channels: High load-bearing capacity, good rigidity, and strong stability.

Square/Rectangular Tubes: Balanced bi-directional bending resistance.

I-Beams/H-Beams: Heavy load-bearing structural materials.

Galvanized Angles, with their long-term corrosion resistance, structural stability, and low maintenance, are the preferred material for steel structure engineering. Wanzhi Group has a complete metal material production chain and strict quality control, offering customers everything from standard products to fully customized galvanized angle steel solutions.