Galvanized C-Channel, also known as galvanized C-section steel, are corrosion-resistant cold-formed steel sections widely used in building roof purlins, wall girts, support members, equipment frames, storage racking, and prefabricated steel structures. As a professional steel supplier, Wanzhi Group possesses a complete production chain and stringent quality control, offering a full range of galvanized C-channel products from standard specifications to custom manufacturing.

Galvanized C-Channel Specifications

| Model | Section Dimensions (H×B×C×t) | Standard Length (m) |

| C80×40×20×2.0 | 80×40×20×2.0 | 6–12 |

| C100×50×20×2.0 | 100×50×20×2.0 | 6–12 |

| C120×50×20×2.5 | 120×50×20×2.5 | 6–12 |

| C140×60×20×2.5 | 140×60×20×2.5 | 6–12 |

| C160×60×20×3.0 | 160×60×20×3.0 | 6–12 |

| C200×70×20×3.0 | 200×70×20×3.0 | 6–12 |

Classification & Applications

C-Channels for Building Purlins

- Section modulus ≥15 cm³/m, excellent bending resistance. Suitable for horizontal load-bearing in roofs/walls, capable of withstanding variable loads such as snow and wind pressure.

C-Channels for Photovoltaic Mounting Systems

- Zinc coating thickness ≥100μm (enhanced corrosion protection), superior wind load resistance. Ideal for quick fastening of PV panels in ground-mounted or rooftop power stations.

C-Channels for Equipment/Racking

- High dimensional accuracy (height tolerance ±0.5mm), can be processed with round or oblong holes as needed. Suitable for modular equipment frame construction.

Special Load-Bearing C-Channels

- Made from high-strength Q355B base material (yield strength ≥355MPa). Some sections include stiffeners on the web for enhanced shear strength. Suitable for heavy equipment bases, long-span supports, etc.

Mechanical Properties (Q355B Material)

| Performance Indicator | Standard Requirement | Typical Value |

| Yield Strength (ReH) | ≥355 MPa | 370–420 MPa |

| Tensile Strength (Rm) | 470–630 MPa | 500–580 MPa |

| Elongation (A) | ≥22% | 24–28% |

| Impact Toughness (20°C) | ≥34J | ≥40J |

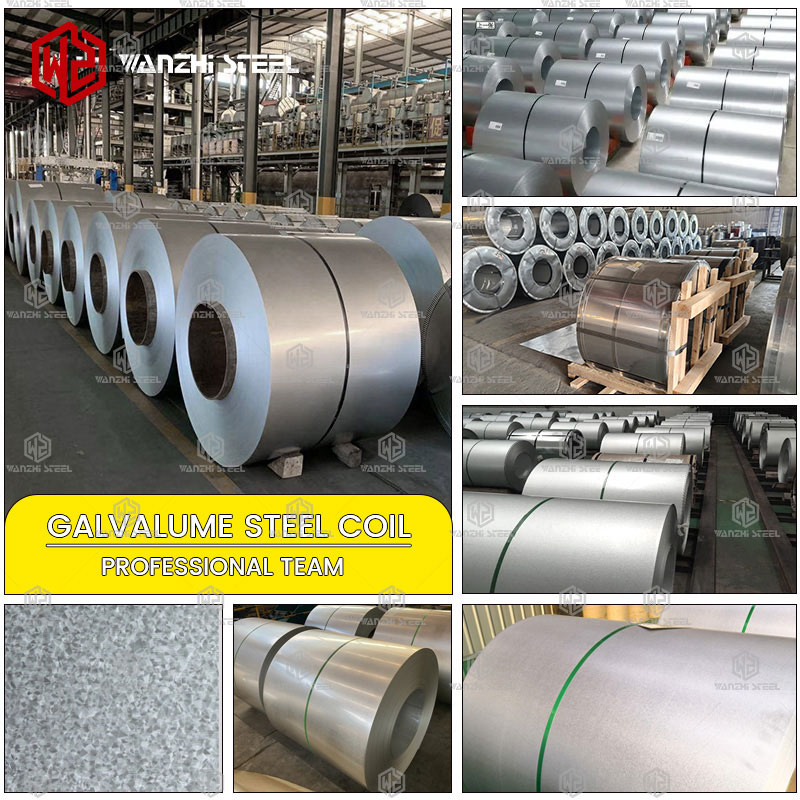

Zinc Coating

Hot-Dip Galvanizing (Preferred for Outdoor/Humid Environments)

- Appearance: Uniform silver-gray surface, thick coating, minor spangling allowed.

- Applications: Building purlins, PV mounting systems, outdoor equipment frames.

Electro Galvanizing (For Dry Indoor Environments)

- Appearance: Smooth surface without spangles, thin and uniform coating.

- Applications: Indoor ceiling joists, internal supports for small equipment.

Features of Galvanized C-Channels

Excellent Corrosion Resistance

- The hot-dip zinc coating provides both physical barrier and electrochemical protection. Service life in outdoor environments can reach 20–40 years, significantly reducing maintenance frequency and costs.

High Section Efficiency & Lightweight

- The C-shaped section optimizes material distribution, improving material utilization by approximately 30%. It offers excellent bending and compression resistance with high load-bearing efficiency per unit weight, making it ideal for long-span, light-gauge steel structures.

Easy Installation & Compatibility

- Wanzhi Group supplies C-channels with standard hole patterns and uniform cross-sections for quick connection with bolts, self-drilling screws, etc., facilitating modular assembly.

Dimensional Flexibility

- The cross-section of Galvanized C-Channels can be customized according to architectural requirements, adapting to non-standard scenarios.

Neat & Aesthetic Appearance

- The galvanized surface presents a uniform silver-gray finish, suitable for exposed structures without additional painting.

Custom Manufacturing Services

Wanzhi Group supports customization of non-standard dimensions, materials, zinc coatings, and hole patterns for Galvanized C-Channels to meet the full-scenario demands of steel structure engineering.

Customization Scope

- Section Customization: Height up to 500mm, width up to 120mm, web thickness up to 12mm.

- Special Sections: Custom lipped C-channels, unequal flange C-channels.

- Length Customization: Precision cutting from 1m to 18m, with end treatments available.

- Zinc Coating Customization: Standard coatings from 60–600 g/m², adjustable based on environmental corrosion levels.

- Value-Added Processing: Wanzhi Factory provides secondary processing such as punching, cutting, bending, and welding (e.g., into C-channel trusses), delivering components ready for direct assembly.

Factory & Quality Control

- Production Base: Located in Xingfu Town, Boxing County, Binzhou City, Shandong Province. Equipped with fully automated cold-forming lines, hot-dip galvanizing lines, and painting lines.

- Quality System Certifications: ISO9001, ISO14001, CE, ASTM A1003, etc.

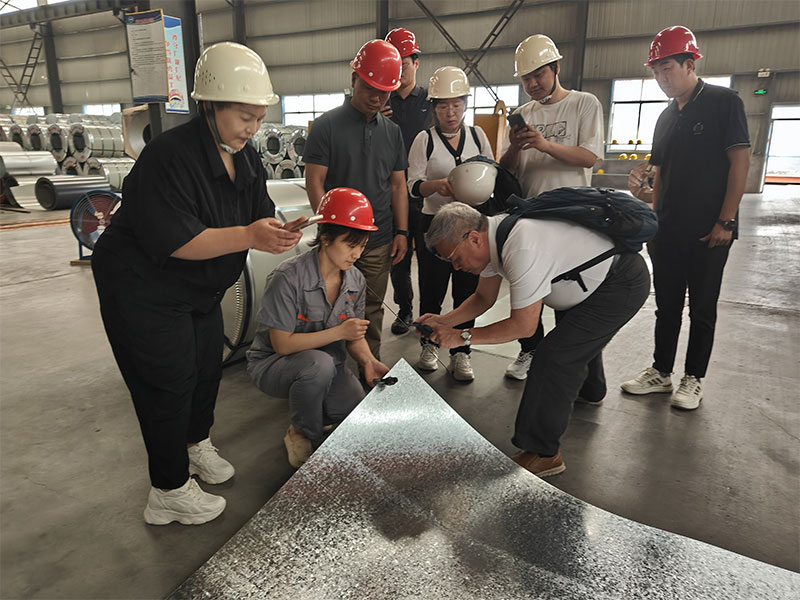

- Laboratory Equipment: Universal testing machines, spectrometers, coating thickness gauges, salt spray test chambers, etc., ensuring full-process quality control from raw material to finished product.

- Delivery Capability: Standard specifications available from stock. Lead time for custom orders: 5–45 working days.

Galvanized C-Channels vs. Plain Carbon Steel C-Channels

| Comparison Aspect | Galvanized C-Channels | Plain Carbon Steel C-Channels (Uncoated) |

| Corrosion Resistance | Excellent – active zinc protection | Poor – relies on paint coatings |

| Service Life | 20–40 years (outdoor) | 5–10 years (requires regular maintenance) |

| Initial Cost | Higher (approx. 30%–60% more) | Low |

| Lifecycle Cost | Low (minimal to no maintenance) | High (cumulative maintenance and replacement costs) |

| Installation Efficiency | High – no on-site anti-corrosion treatment needed | Low – requires on-site painting or fireproofing |

| Environmental Impact | Favorable – zinc is recyclable | Moderate – paints may contain volatile compounds |

| Suitable Environments | Universal – indoor/outdoor, especially high humidity, industrial atmospheres | Limited to dry indoor or short-term outdoor use |

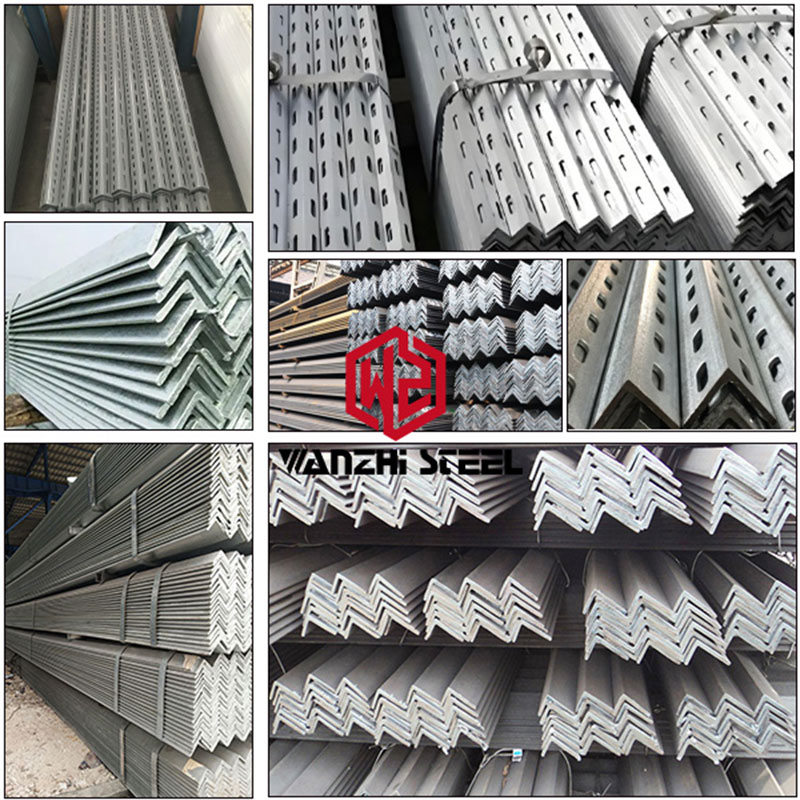

Wanzhi Galvanized Section Steel Product Series

In addition to Galvanized C-Channels, we also supply:

Galvanized Angles: L-shaped section for bi-directional support; suitable for frames, guardrails.

Z-Purlins: Z-shaped section with excellent torsional resistance; suitable for long-span purlins.

Channels: U-shaped section with high load-bearing capacity; suitable for heavy equipment bases.

Square/Rectangular Tubes: Closed sections with balanced bi-directional bending resistance; suitable for columns, beams.

I-Beams/H-Beams: Heavy load-bearing sections; suitable for main building structures, bridges.

Customer visit

Galvanized C-Channels, with their comprehensive advantages of lightweight design, high bending resistance, and long-term corrosion protection, have become an essential component in modern light-gauge steel structure systems. Wanzhi Group provides galvanized C-channel solutions—from standard products to deep customization—for clients across various sectors. Please contact us for more information, solutions, and pricing.