Galvanized H Beam is one of the common forms of galvanized structural steel. It features a hot-dip galvanized H-shaped cross-section with wide, uniform-thickness flanges and a straight transition between the web and flanges. It combines the superior bidirectional load-bearing capacity of H-section steel with the corrosion resistance and weathering advantages of the galvanized coating.

Specifications (GB/T 11263)

| Specification Model (GB) | Cross – Section Dimensions H×B×t₁×t₂ (mm) | Theoretical Weight (kg/m) | Standard Length (m) |

| HW 100×100 | 100×100×6×8 | 17.2 | 6 – 12 |

| HW 200×200 | 200×200×8×12 | 50.5 | 6 – 12 |

| HM 350×250 | 350×250×9×14 | 79.7 | 6 – 12 |

| HN 400×200 | 400×200×8×13 | 66.0 | 6 – 12 |

- H – Section height, B – Flange width, t₁ – Web thickness, t₂ – Flange thickness.

- HW denotes wide-flange H-section steel, HM denotes medium-flange H-section steel, HN denotes narrow-flange H-section steel.

Classification by Type

- Wide-flange H-section (HW): Flange width is nearly equal to height. Features wide flanges and high sectional moment of inertia, offering excellent bending and compression resistance with superior overall stability.

- Medium-flange H-section (HM): Flange width lies between wide-flange and narrow-flange types. Moderate width balances load-bearing capacity and cost-effectiveness, providing well-rounded performance.

- Narrow Flange H-Beam (HN): Features narrow flanges and a taller web, prioritizing unidirectional bending performance optimization. Offers more economical material distribution when used as beams.

Applications

- Construction Engineering: Main beams for industrial plants, high-rise steel structure beams/columns, load-bearing frameworks for light steel buildings, spatial load-bearing structures for large venues, main floor beams.

- Bridge Engineering: Internal cross-girders/main girders for long-span box girders, pier supports, bridge guardrail supports.

- Machinery Manufacturing: Heavy machinery bases, crane main girders, mining conveyor supports.

- Municipal & Energy: Urban rail transit platform structures, main components for power transmission towers, main steel structures for large billboards, internal supports for wind turbine towers.

Advantages of Galvanized H-Beams

Exceptional Structural Stability

- Galvanized H-beams feature high bidirectional moment of inertia, delivering superior combined bending, compression, and torsion resistance for complex load-bearing applications.

Superior Corrosion Resistance and Durability

- The hot-dip galvanized coating (with a maximum thickness of 600g/m²) provides long-term cathodic protection, making it suitable for outdoor, humid, and industrial atmospheric environments with a service life exceeding 30 years.

Ease of Fabrication and Installation

- Hot-dip galvanized steel can be cut, drilled, and welded as needed. The coating exhibits strong adhesion and resists peeling after processing. As a standard rolled profile, it offers high dimensional accuracy and facilitates efficient construction through high-strength bolted connections.

High Material Utilization

- Optimized cross-sectional distribution enables steel savings compared to alternative profiles while maintaining equivalent load-bearing capacity. This offers significant economic benefits, particularly in long-span, heavy-load structures.

Outstanding Overall Benefits

- Although the per-ton cost exceeds that of galvanized I-beams, the overall project cost proves more advantageous in long-span and complex loading scenarios.

Galvanized H Beam vs Galvanized Steel I Beam

| Comparison Item | Galvanized H Beam | Galvanized I Beam |

| Cross – Section Shape | In the shape of “H” | In the shape of “I” |

| Flange Characteristics | The inner and outer surfaces are parallel, with wide flanges and uniform thickness | The inner surface has an inclination, with narrow flanges, being thick inside and thin outside |

| Mechanical Properties | Good biaxial bending resistance and strong torsional resistance | Excellent uniaxial bending resistance and weak torsional resistance |

| Applications | Columns, large – span (≥12m) beams, biaxial – loaded frames | Uniaxial – bending beams, horizontal members with small to medium spans |

| Connection | Easy to connect | Often requires wedge – shaped shims |

| Economy | High comprehensive load – bearing efficiency | Highest material utilization when used as a uniaxial beam |

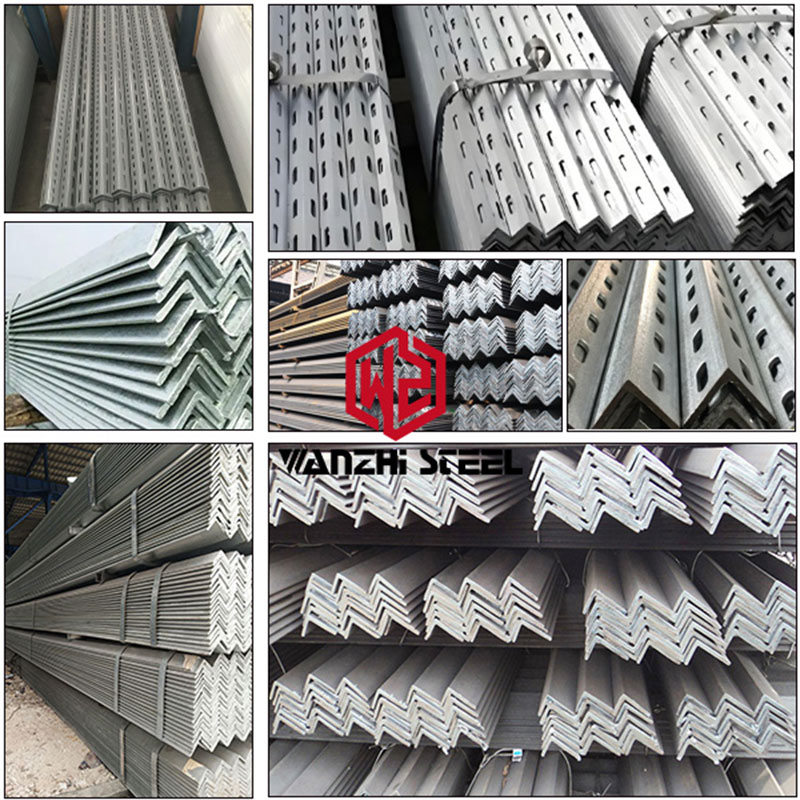

Galvanized H Beam Factory

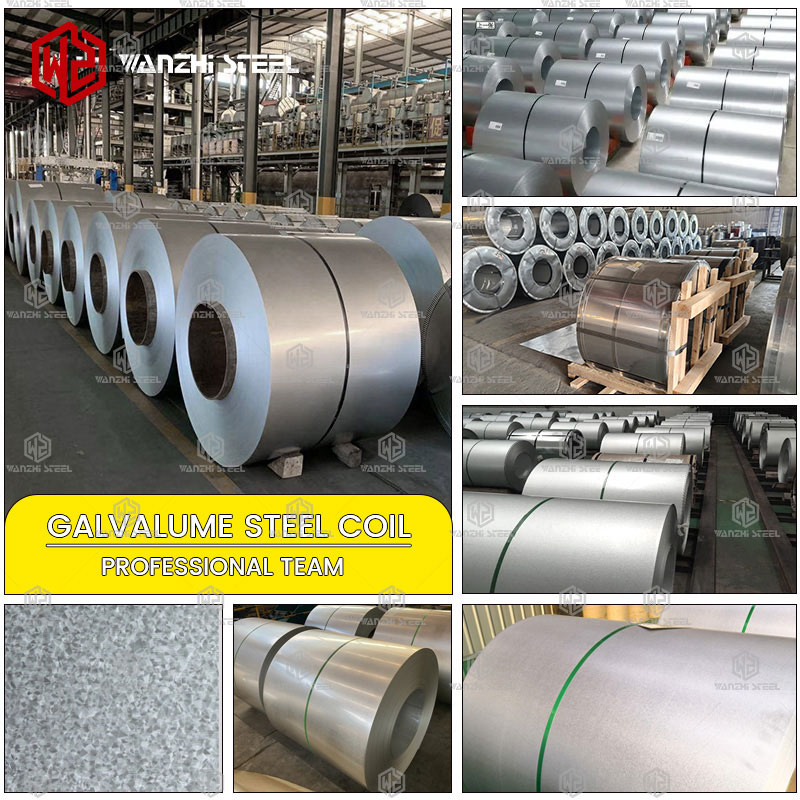

Wanzhi Group, as a professional supplier of metal materials, operates Shandong Wanzhi Steel Co., Ltd., which features advanced hot-rolled and welded H-beam production lines along with supporting hot-dip galvanizing facilities. The company manufactures galvanized H-beams, galvanized I-beams, and other products in various specifications. Additionally, the factory houses production lines for carbon steel, stainless steel, color-coated steel, and alloy steel, with an annual capacity of 600,000 tons and delivery times ranging from 5 to 45 business days.

We support customization of dimensions, materials, and zinc coating thickness for all galvanized structural steel products, including Galvanized H Beams. Pre-processing services such as cutting, punching, and welding are available. Simultaneously, we provide high-precision, corrosion-resistant structural steel and customized solutions for global industries including construction, bridges, energy, and heavy machinery.