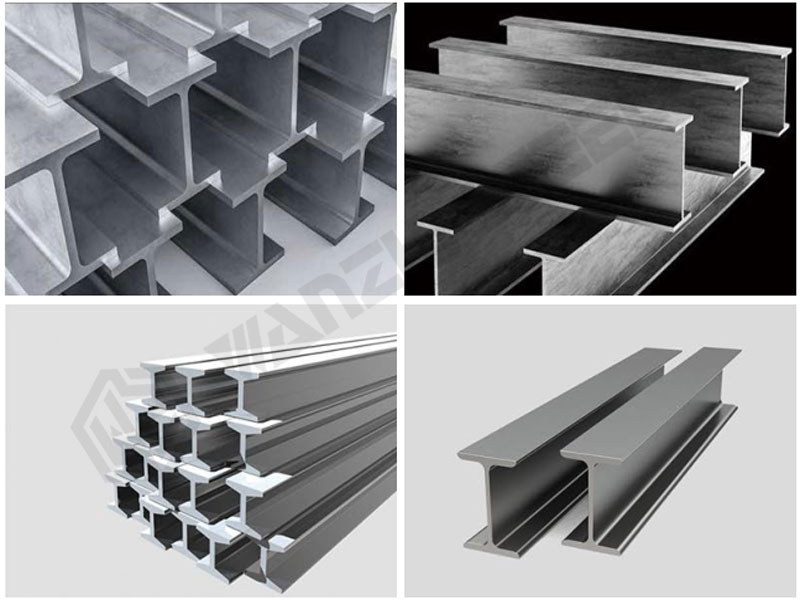

Galvanized I Beam, one of the common forms of galvanized structural steel, is a hot-dip galvanized steel section with an “I”-shaped cross-section. Featuring narrow, thick flanges and a thin, tall web, it combines the structural load-bearing capacity of an I-beam with the corrosion resistance and weathering advantages of a galvanized coating. It serves as a core load-bearing component in construction, bridges, and machinery manufacturing.

Specifications of Galvanized I Beam

| Specification Example (GB) | Cross-sectional Dimensions H×B×d×t (mm) | Theoretical Weight (kg/m) | Standard Length (m) |

| I16 | 160×88×6.0×9.9 | 20.5 | 6 – 12 |

| I25a | 250×116×8.0×13.0 | 38.1 | 6 – 12 |

| I36a | 360×136×10.0×15.8 | 60.0 | 6 – 12 |

| I50a | 500×158×12.0×20.0 | 93.6 | 6 – 12 |

H-Height, B-Flange width, d-Web thickness, t-Average flange thickness.

Material of Galvanized I-Beams

The base material for Wanzhi Group galvanized I-beams is low-carbon structural steel or low-alloy high-strength steel, requiring good weldability, plasticity, and suitability for galvanizing.

- Chinese National Standard: Q235B, Q355B, etc.

- American ASTM Standard: ASTM A36, ASTM A572 Gr.50, etc.

- European EN Standard: S235JR, S355JR, etc.

- Galvanizing Process: Hot-dip galvanizing is employed, with zinc coating thickness typically ranging from 30-600 g/m².

Model Classification

Standard I-Beam (I): Features moderate flange width and uniform web thickness, representing the most commonly used type.

Lightweight I-Beam (QI): Offers narrower flanges, thinner webs, and reduced weight for the same height.

Heavy-duty I-beams (HI): Feature thicker flanges and increased web thickness for enhanced strength.

Applications of Galvanized I-Beams

Galvanized I-beams exhibit excellent unidirectional bending resistance but weaker torsional performance. They are suitable for loads perpendicular to the web plane and can be connected and secured via welding, high-strength bolts, or bolt-welded joints.

- Construction Engineering: Roof beams, floor beams, secondary beams in multi-story buildings, load-bearing frames for prefabricated buildings, support beams for canopies and carports.

- Bridge Engineering: Transverse connecting beams for small-to-medium span bridges, guardrail support structures.

- Machinery Manufacturing: Base frames for mechanical equipment, supports for conveying systems, auxiliary load-bearing components for cranes.

- Municipal Engineering: Signage supports, streetlight pole foundations, load-bearing columns for temporary fencing.

Advantages of Galvanized I-Beams

Superior Corrosion Resistance and Weathering Performance: Hot-dip galvanized coatings isolate steel from air and moisture, significantly extending service life and reducing long-term maintenance costs.

High Bending Strength: The I-shaped cross-section concentrates material in tension/compression zones, delivering exceptional resistance to bending forces.

Processing Flexibility: Easily cut, drilled, and welded to meet customized structural requirements. The galvanized coating exhibits strong adhesion, minimizing peeling after fabrication.

Cost-effective: Compared to other shaped galvanized beam, I-beams consume less raw material and offer lower costs while delivering equivalent load-bearing capacity and span.

Easy installation: As a standard rolled section with consistent dimensions, it enables rapid construction.

Galvanized I Beam vs Galvanized H Beam

| Comparison Item | Galvanized I Beam | Galvanized H Beam |

| Cross-sectional Shape | The cross-section is in an “I” shape. | The cross-section is in an “H” shape. |

| Flange Characteristics | The inner surface has an inclination. The outer end of the flange is thin, and the inner end is thick. | The inner and outer surfaces are parallel, and the flange thickness is uniform. |

| Mechanical Properties | It has unidirectional bending resistance and weak torsional resistance. The load is concentrated on the web. | It can withstand bidirectional bending and torsion, with more even force distribution and stronger overall stability. |

| Optimal Applications | Suitable for horizontal beams with unidirectional bending and small to medium-span structures. | Can be used as beams, columns, and for large-span (≥12m) structures. |

| Connection | Sometimes, gaskets are required. | Connection is more convenient. |

| Economic Efficiency | When used as a beam, it has the highest material utilization rate. | Offers higher overall cost-effectiveness. |

Galvanized I Beam Factory

Wanzhi Group, as a professional metal materials factory supplier, operates Shandong Wanzhi Steel—a facility equipped with production lines for galvanized steel, structural steel, carbon steel, stainless steel, color-coated steel, and alloy steel. With an annual output of 6.6 million tons, we provide customized solutions for construction, home appliances, industrial applications, and more.

We support customization for various specifications and shapes of beam steel and structural steel, including Galvanized I Beams. Leave us a message with your requirements to get a free quote!