Galvanized steel roofing sheets are used on residential and commercial building roofs, industrial plants, logistics warehouses, agricultural greenhouses, and other structures. They are subject to loads such as wind, snow, rain, and maintenance personnel, and are exposed to rain, condensation, and corrosive environments.

Structural Design

Galvanized steel roofing sheets must be designed based on building drainage, lighting, and ventilation requirements. Roofing sheets typically feature a high-peak design (slope ≥ 3%), providing exceptional rigidity and rapid, effective drainage.

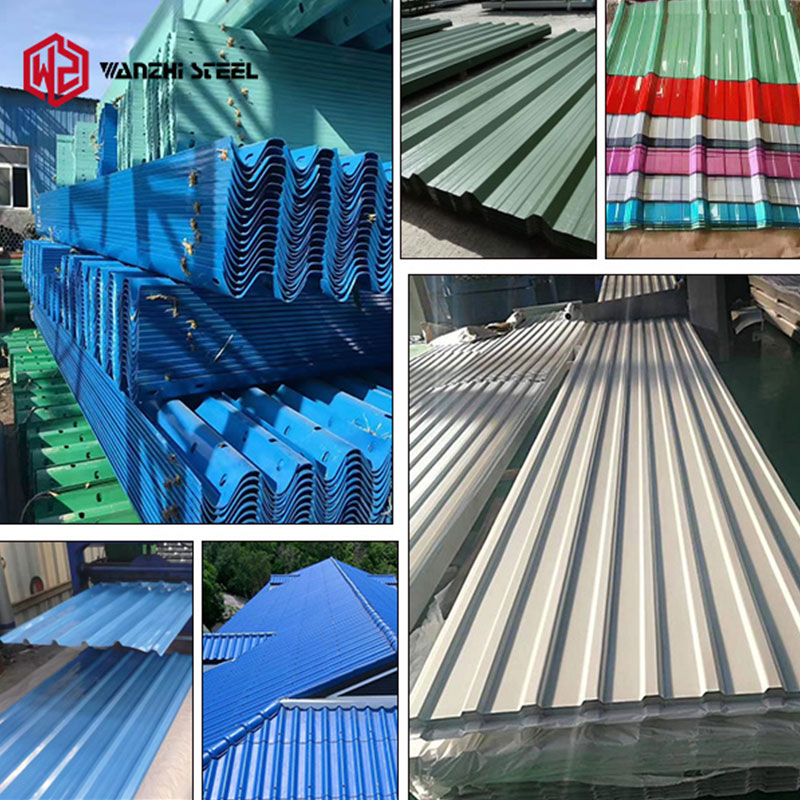

Common Sheet Types

- GI Corrugated Sheet: Features traditional curved peaks, is simple to manufacture, and offers high versatility.

- GI Trapezoidal Sheet: The most commonly used sheet type in modern industrial construction. Its trapezoidal ribs provide optimal rigidity and load distribution.

- GI Tile Panel: Mimics the shape of traditional tiles, offering the performance of metal sheets with a more traditional appearance.

Advantages

- Waterproofing and Drainage: Galvanized steel roofing sheets offer excellent waterproofing. The peaks of the sheet ensure rapid drainage of rainwater, significantly reducing the risk of leaks caused by accumulated water.

- Wind-Resistance and Load-Bearing: The corrugated surface structure allows it to withstand greater loads (snow, wind, and people) than galvanized GI plain sheet at the same thickness, making it less susceptible to bending. In areas with high wind pressure, roof panels require increased purlin spacing, additional fixing points, or the use of wind-resistant clamps to enhance stability. Some roof panels also need to bear the additional weight of accumulated snow and equipment.

- Insulation: Roof panels are often combined with insulation layers (such as glass wool or rock wool) to reduce building energy consumption and improve roof thermal performance.

Applications of Galvanized Steel Roofing Sheets

- Industrial Buildings: Roofs of various industrial plants and production workshops.

- Logistics and Warehousing: Roofs of large warehouses and distribution centers.

- Agricultural Buildings: Livestock farms, greenhouses, and agricultural product processing workshops.

- Public Facilities: Awnings for stadiums, train platforms, and large market places.

- Temporary Buildings: Temporary construction sites and emergency facilities.

How to Choose High-Quality Galvanized Steel Roofing Sheets?

Is it a large-span public building roof or a general residential roof? Choosing a galvanized steel roofing sheet that will protect your project for years to come requires careful consideration of factors such as the coating, substrate, form, surface, and quality. Consider the characteristics of the galvanized roof sheet and the application requirements to select the most cost-effective solution.

- Coating Weight: This determines the corrosion lifespan of the roofing sheet. It is usually indicated by “Zxxx” (e.g., Z180 represents a total coating weight of 180g/㎡ on both sides). For galvanized roofing, we recommend choosing Z180 (180g/m2) or higher. For coastal or high-humidity areas, choose Z275 or higher.

- Baseboard Thickness: This affects strength and load-bearing capacity. Common thicknesses range from 0.5mm to 0.8mm. Thickness is primarily determined by purlin spacing and the application environment.

- Sheet Design: Selecting a sheet with a higher wave height (e.g., 25mm or higher) can effectively improve stiffness and drainage efficiency, preventing water accumulation.

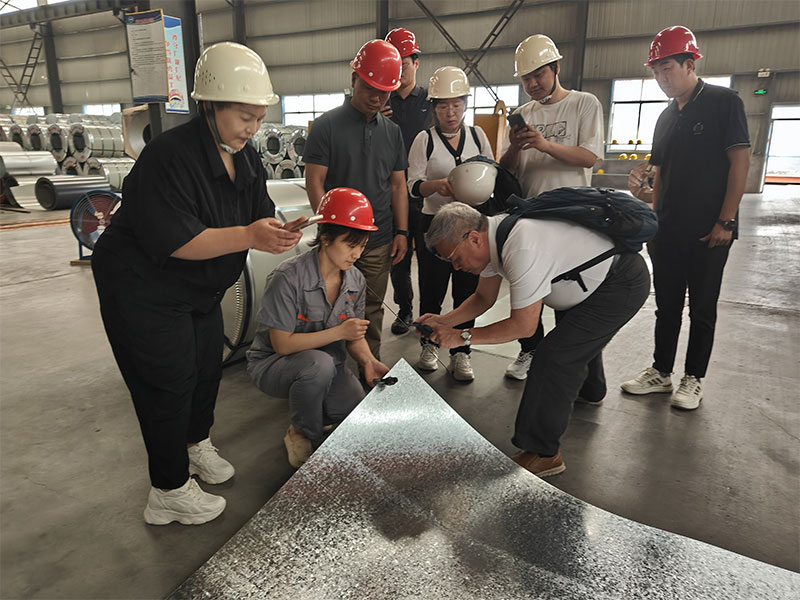

- Surface: Prefer low-spangle or no-spangle finishes for better corrosion resistance; avoid visible scratches, bubbles, or zinc nodules.

- Brand and Warranty: Choose products from reputable steel mills for guaranteed zinc coating adhesion, uniformity, and a quality assurance system.

- Quality Inspection: Ensure smooth, burr-free cuts, a crisp sound when tapped, and a third-party inspection report.

Reliable Galvanized Steel Roofing Sheets

Wanzhi Group‘s galvanized steel roofing sheets offer excellent corrosion resistance and formability, making them widely used in construction, machinery, automobiles, home appliances, and other fields. Our factory boasts multiple galvanizing lines, a painting line, and galvanized steel roofing sheet forming machines, with an annual production capacity of 600,000 tons. Furthermore, our factory is ISO9001 and ISO14001 certified. If you require pricing on galvanized steel roofing sheets, please contact us.