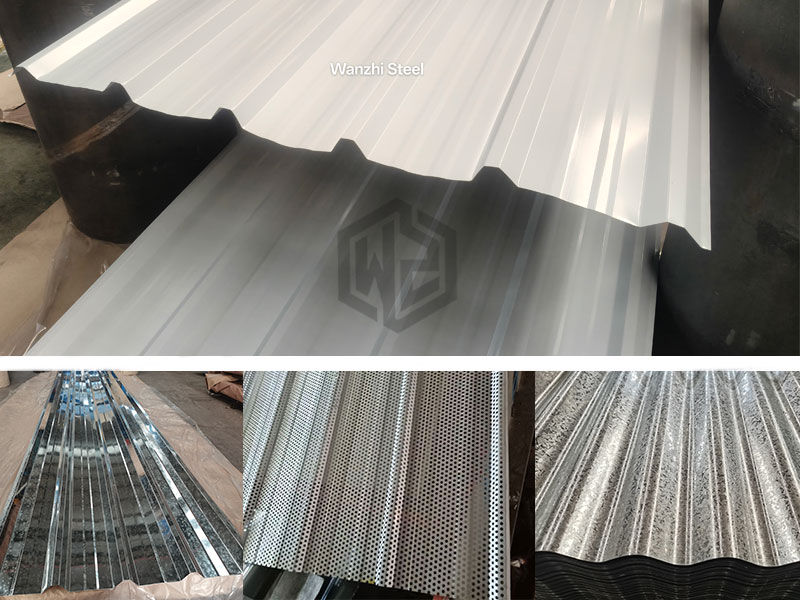

Galvanized trapezoidal sheet refers to building panels formed by cold-rolling hot-dip galvanized steel coils into trapezoidal corrugated profiles. Characterized by corrosion resistance, high strength, and ease of processing, it has become the preferred material for roofing and wall systems in industrial plants, warehousing logistics, and large public buildings.

Galvanized Trapezoidal Sheet for Sale

Wanzhi Group provides customized solutions for galvanized trapezoidal sheets suitable for applications across various industries. Leave us a message with your required model or product images to get a free quote!

Features

- Superior Corrosion Resistance: The galvanized coating provides sacrificial electrochemical protection for the steel substrate, preventing rust.

- High Structural Strength: The trapezoidal cross-section design grants the sheet exceptional load-bearing capacity and wind pressure resistance.

- Excellent Plasticity and Toughness: Adaptable to various shapes and deformation requirements while maintaining good mechanical properties.

- Good Heat Resistance: Maintains stability in high-temperature environments with minimal deformation.

- Lightweight and Cost-Effective: Compared to traditional materials like concrete, galvanized steel sheet has low self-weight, reducing structural loads and overall construction costs.

- Easy Installation: Standard fastening methods and large single-sheet coverage enable rapid and efficient installation.

- Low Maintenance: Corrosion-resistant surface requires minimal post-installation upkeep.

- Excellent Weldability: Capable of forming strong connections with other materials, widely used in manufacturing machinery and industrial components.

Common Specifications

- Sheet Thickness (t): Refers to the base material thickness, typically ranging from 0.4mm to 1.2mm. Roof panels commonly use 0.5mm-0.8mm.

- Corrugation Height (H): Refers to the height of the trapezoidal ribs, commonly 25mm, 40mm, 50mm, 75mm, or even higher. Higher corrugation height increases rigidity and load-bearing capacity.

- Corrugation Pitch (P): The distance between the centerlines of adjacent trapezoidal ribs, commonly 200mm, 300mm, 400mm, etc.

- Effective Coverage Width (B): The actual width covered by a panel after installation. It equals the panel’s unfolded width minus the overlap width.

Common Trapezoidal Panel Designations

e.g., YX25-205-820, YX75-380-760.

- YX typically denotes profiled sheet metal.

- The first set of numbers (e.g., 25/75) indicates wave height.

- The second set of numbers (e.g., 205/380) indicates wave pitch.

- The third set of numbers (e.g., 820/760) indicates effective coverage width.

e.g., T+number

- T-35 (35mm wave height)

- T-50 (50mm wave height)

- T-75 (75mm wave height)

- T-100 (100mm wave height)

- and other customer-customized profiles.

Classification of Galvanized Trapezoidal Sheets

By Galvanizing Process:

- Hot-Dip Galvanized Trapezoidal Sheets: After continuous annealing in hot-dip galvanizing equipment, the substrate is immersed in molten zinc baths to form an alloy layer on the steel surface before re-forming. This coating offers excellent adhesion and corrosion resistance.

- Electrogalvanized Trapezoidal Sheet: Utilizes electrochemical principles to deposit zinc onto the steel surface before forming. The coating is uniform but offers relatively weaker corrosion resistance.

By Base Material Type:

- Cold-Rolled Base Galvanized : Uses cold-rolled steel as the base material for galvanizing and forming. Suitable for applications requiring higher strength.

- Hot-Rolled Galvanized : Utilizes hot-rolled steel as the substrate for galvanization and subsequent forming. It offers lower cost and is suitable for general construction and decorative applications.

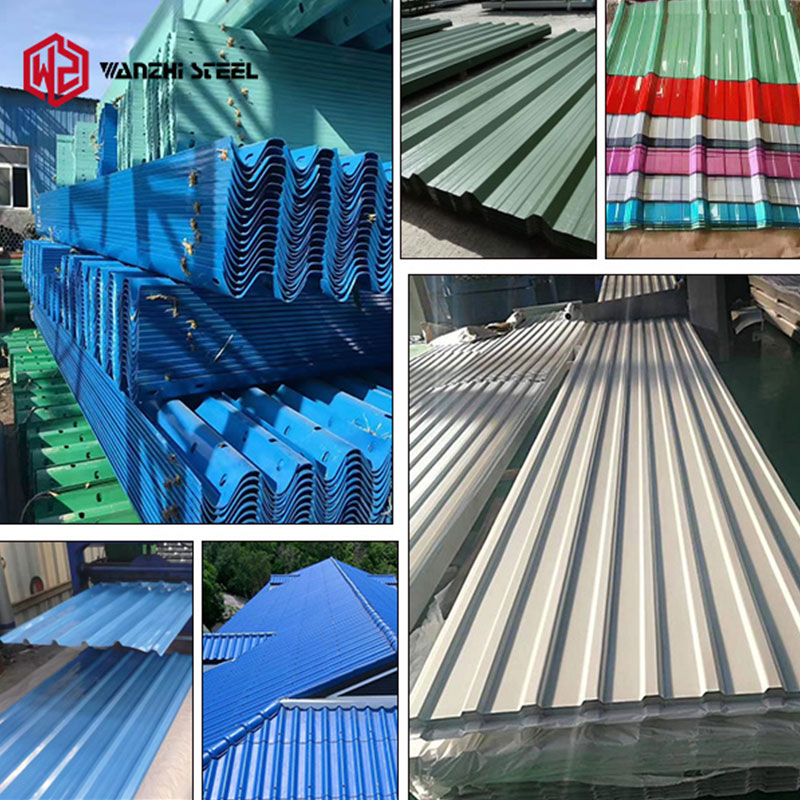

Applications of Galvanized Trapezoidal Sheet

Galvanized trapezoidal sheet meets structural strength, corrosion resistance, and processing requirements for industrial buildings, logistics warehouses, commercial facilities, agricultural structures, and more. It is widely used for roofing, wall cladding, and steel fabrication across diverse construction sectors.

- Roofing Systems: The primary roofing material for industrial plants, warehouses, logistics centers, and manufacturing facilities.

- Wall Systems: Used as exterior wall panels for industrial buildings.

- Public Buildings: Roofing and wall cladding for stadiums, exhibition centers, airports, train stations, and similar structures.

- Modular/Temporary Structures: Roofing and wall panels for prefabricated buildings.

- Partition Walls: Interior partition walls within large-scale buildings.

- Floor Decking: A specialized closed-end trapezoidal panel (also known as corrugated metal sheet) used in conjunction with reinforced concrete as permanent formwork and load-bearing reinforcement.

Why Choose Our Galvanized Trapezoidal Sheet?

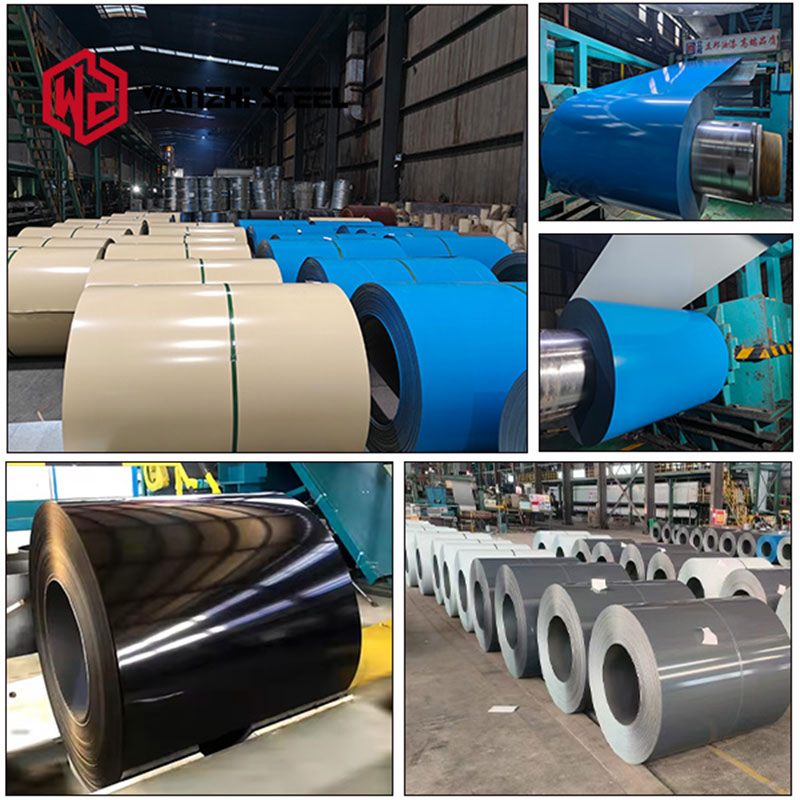

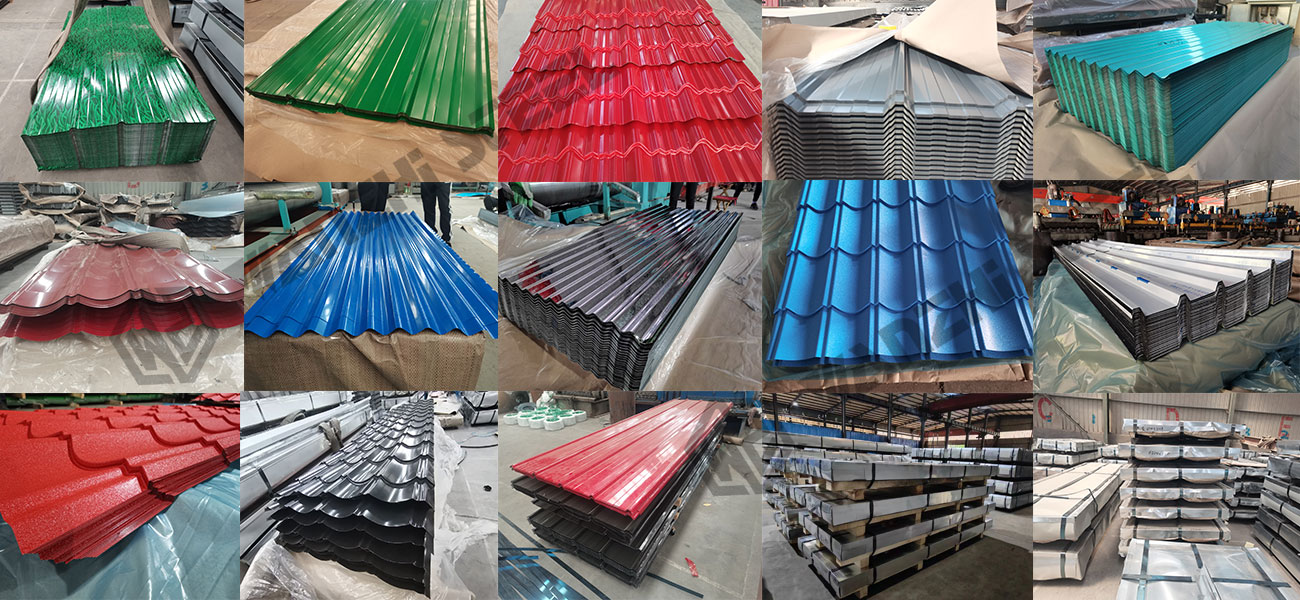

Wanzhi Group is a coated steel manufacturer based in China. We produce coils and sheets of various metal materials including galvanized steel, aluzinc, zinc-aluminum-magnesium, aluminum-magnesium-manganese, aluminum, and stainless steel. We also offer additional services such as slitting, bending, leveling, forming, stamping, punching, and painting. We offer diverse solutions tailored to your application needs, including galvanized trapezoidal sheet, galvalume trapezoidal sheet, stainless steel trapezoidal sheet, and prepainted trapezoidal sheet.

Premium Base Material: We utilize high-quality galvanized steel coil (steel grades DX51D/DX52D+Z/SGCC/S350GD) produced on our proprietary galvanizing line, ensuring uniform zinc coating and strong adhesion.

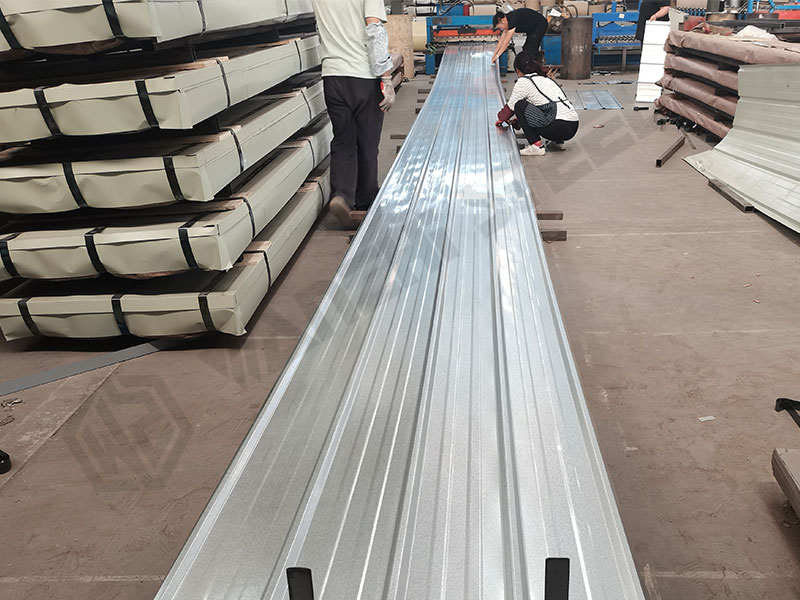

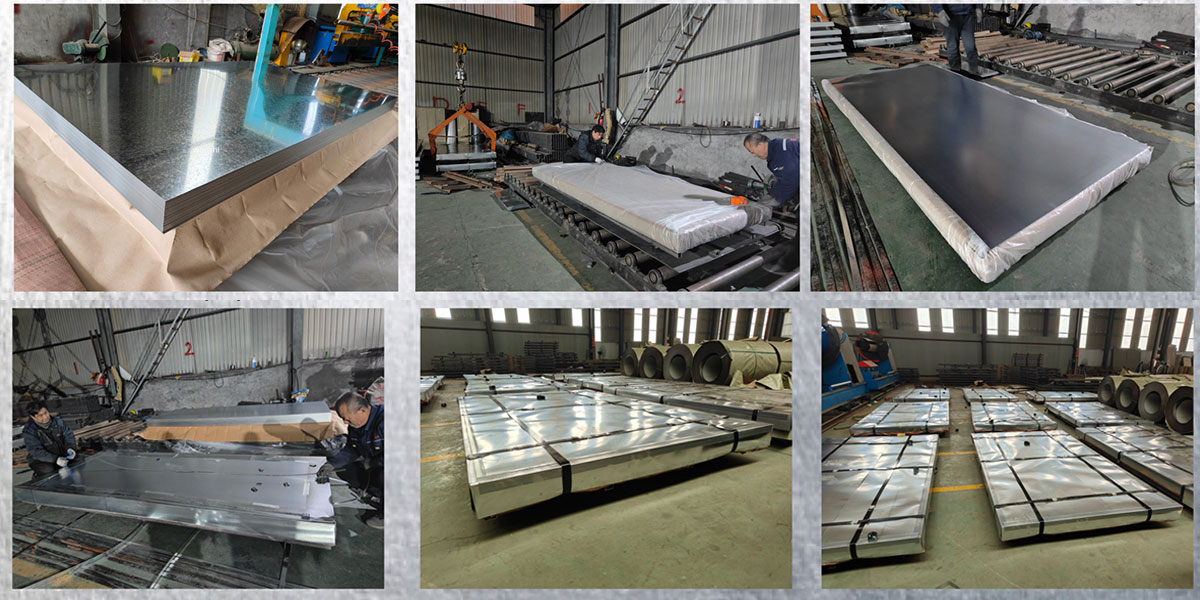

Precision Roll Forming: Advanced cold-forming lines guarantee dimensional accuracy, consistent wave profiles, and seamless interlocking.

Diverse Options: We offer multiple popular wave heights and sheet profiles, guaranteeing structural safety while meeting diverse architectural aesthetic requirements.

One-Stop Service: From raw materials to finished panels, we provide comprehensive processing services including slitting, roll forming, and cut-to-length cutting, saving you time and costs.

Galvanized Trapezoidal Sheet – Buying Guide

| Project Requirements | Recommended Specifications | Description |

| General industrial factory buildings (roofs) | Thickness: 0.5mm – 0.7mm Zinc coated: Z120 – Z150 Wave height: 35mm – 75mm |

Balance economy and structural requirements to meet basic drainage and load-bearing needs. |

| Areas with strong wind pressure/heavy snowfall | Thickness: ≥0.8mm Zinc coated: Z150 – Z200 Wave height: ≥75mm |

Increase the thickness of the sheet and wave height to enhance stiffness and load-bearing capacity. |

| Highly corrosive environments (coastal areas, industrial zones) | Thickness: 0.6mm – 0.8mm Zinc coated: Z200 – Z275 Or use galvalume sheet (GL) |

Use high-zinc layers or more corrosion-resistant base plates to extend service life. |

| Wall linings/inner panels | Thickness: 0.4mm – 0.5mm Zinc layer: Z90 – Z120 |

With lower load-bearing requirements, thinner and more economical sheets can be selected. |

GI Galvanized Trapezoidal Sheet VS PPGI Trapezoidal Sheet

| Item | Galvanized Trapezoidal Plate (GI) | Pre-painted Galvanized Iron Trapezoidal Plate (PPGI) |

| Base Plate | Cold-rolled Steel, Galvanized Steel | Cold-rolled Steel, Galvanized Steel (as the base for coating) |

| Coating | 99% Pure Zinc | – (The coating here refers to the pre-painted layer on top of the galvanized layer) |

| Coating Thickness | – (Not specified in the original text) | – (Not specified in the original text) |

| Advantages | Lowest cost, Pure industrial style | Rich color options, Highly decorative |

| Performance | Corrosion-resistant, High strength, Easy to process | Corrosion-resistant, UV-resistant, High strength, Heat-resistant, Aesthetically pleasing |

| Disadvantages | Single appearance (silver-white), Average weather resistance | Higher cost |

| Applications | Temporary or internal partition buildings with no aesthetic requirements and tight budgets | Preferred choice for most modern industrial and civil buildings |

We are committed to providing global customers with high-quality, cost-effective metal building solutions. Whether you require standard Galvanized Trapezoidal Sheet products or customized services, please feel free to contact us for the latest quotations and technical consultation.