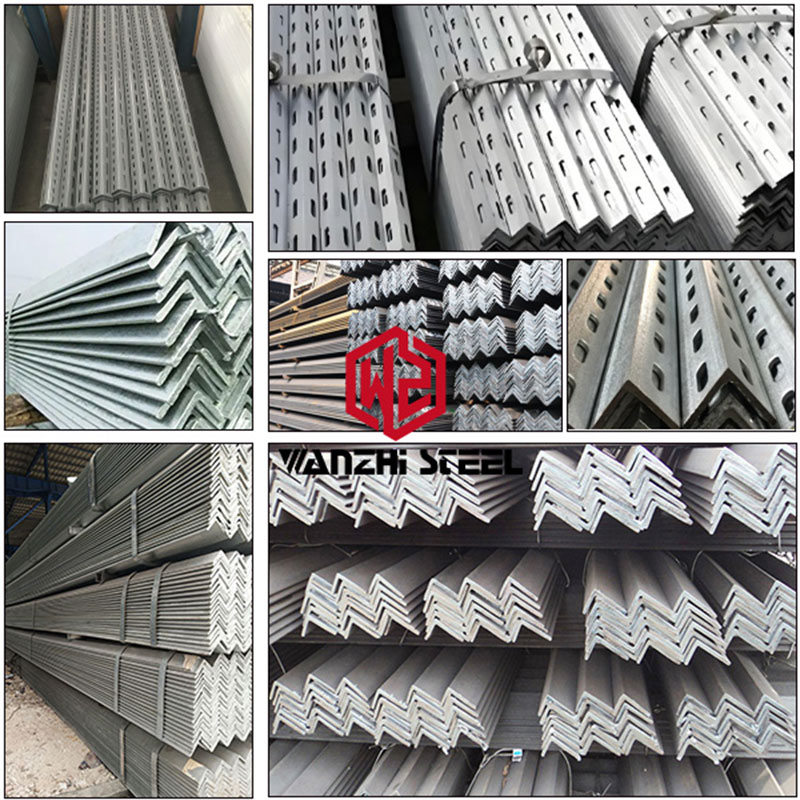

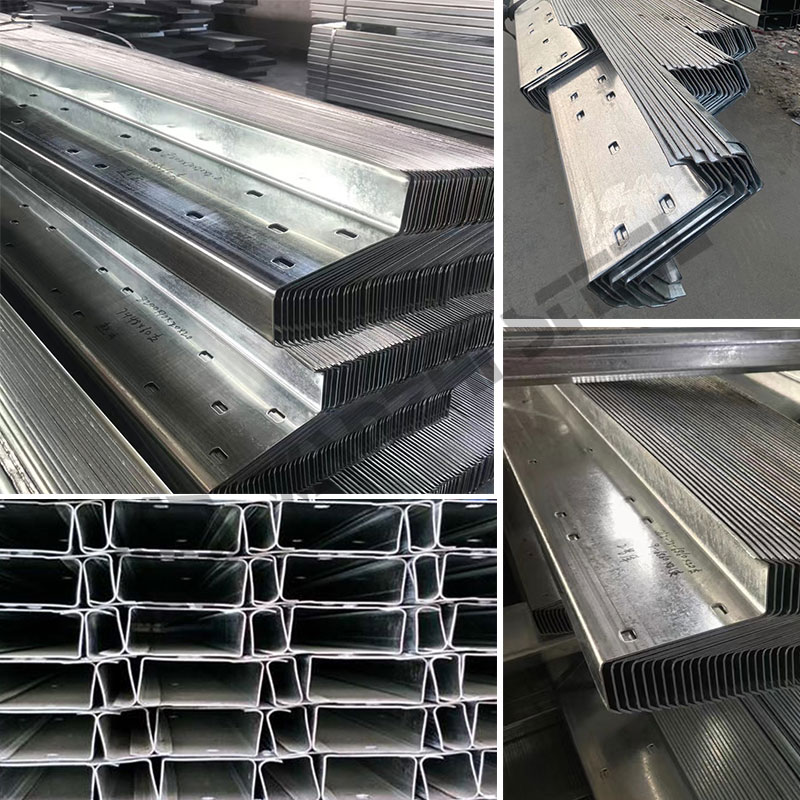

Galvanized Z-Purlin, also known as galvanized Z-section steel, is a galvanized steel product formed into a “Z-shaped cross-section” through a cold-roll forming process. Its dimensions are adjustable. As a professional section steel supplier, Wanzhi Group provides both standard and customized galvanized Z-purlins, covering various types such as equal-section, lipped, pre-punched, etc., to meet diverse needs ranging from industrial plants, logistics warehouses, transportation, and infrastructure construction to distributed photovoltaic (PV) power stations.

Galvanized Z-Purlin Specifications

The core dimensions of Galvanized Z-Purlin are based on section height (H), flange width (B), web thickness (d), and lip width (C). Combined with theoretical weight and standard length, they form a three-tier specification system (small, medium, large) to meet different span and load requirements.

| Specification Type | Main Dimensions (mm) H × B × d × C | Theoretical Weight (kg/m) | Standard Length (m) |

| Small Z-Purlins | 80 × 40 × 2.0 × 15 | 2.15 | 6–12 |

| 100 × 50 × 2.5 × 15 | 2.88 | 6–12 | |

| 120 × 50 × 2.5 × 15 | 3.22 | 6–15 | |

| Medium Z-Purlins | 140 × 60 × 3.0 × 20 | 4.15 | 6–15 |

| 180 × 70 × 3.5 × 20 | 5.82 | 6–18 | |

| 200 × 75 × 4.0 × 20 | 6.75 | 6–18 | |

| Large Z-Purlins | 250 × 80 × 4.5 × 25 | 8.95 | 6–20 |

| 300 × 90 × 5.0 × 25 | 11.42 | 6–20 | |

| 350 × 100 × 6.0 × 30 | 15.80 | 6–20 |

Galvanized Z-Purlin Classification

Based on their structural role and installation environment in engineering projects, galvanized Z-purlins can be categorized into three main types, precisely matching different load-bearing and assembly requirements. They are widely used in automotive, railway vehicles, building doors/windows, transportation racks, electrical cabinets, highway guardrails, building steel structures, containers, steel formwork and scaffolding, solar mounting systems, shipbuilding, bridges, transmission towers, sheet piling, cable trays, agricultural machinery, furniture, storage, guide rails, studs, greenhouse frames, pipe supports, municipal construction, and more.

Small Galvanized Z-Purlins

- Suitable for light-duty cladding and auxiliary structures, such as light-gauge color steel sheet roofs, sandwich panel wall framing, indoor ceiling joists, light canopies, wall purlins for small warehouses, residential PV mounting, display racks, etc.

Medium Galvanized Z-Purlins

- The primary specification for roof and wall purlins in medium-span industrial and commercial buildings, roofs of medium-sized logistics warehouses, standard industrial plant purlins, main beams for distributed PV power stations, and large-span exhibition hall roofs.

Large Galvanized Z-Purlins

- Designed specifically for roofs of heavy-duty industrial plants (e.g., machinery factories, steel mills), purlins for large logistics park warehouses, main beams for centralized PV mounting systems, and special load-bearing scenarios in mega-sized plants (span > 18m).

Zinc Coating

The corrosion resistance of Galvanized Z-Purlin relies on the dual protection of the zinc coating: physical barrier + sacrificial anode. Wanzhi Group primarily uses two galvanizing processes: Hot-Dip Galvanizing (mainstream) and Cold Galvanizing (for light-duty scenarios).

Hot-Dip Galvanizing Process (Preferred for Outdoor/Humid Environments)

- Appearance: Uniform silver-gray surface, minor spangling allowed, complete coating.

- Service Life: 15-25 years outdoors, 10-18 years in industrial humid environments.

- Suitable Scenarios: Most construction applications.

Cold Galvanizing Process (For Dry Indoor Environments)

- Appearance: Smooth surface without spangles, uniform color.

- Service Life: 5-8 years in dry indoor environments.

- Suitable Scenarios: Avoid outdoor or humid environments.

Galvanized Z-Purlin Features

Compared to galvanized C-purlins and channels, galvanized Z-purlins possess four irreplaceable features due to their “Z-shaped cross-section” structural design and the corrosion protection of the zinc coating.

Superior Overlap Design

- The flanges of the Z-shaped section allow for continuous overlapping. When connected with high-strength bolts, they form a continuous beam, significantly reducing mid-span bending moments. This allows for wider purlin spacing or thinner sections, achieving structural optimization and cost savings.

Excellent Mechanical Performance

- The overall bending performance of a Galvanized Z-Purlin increases by approximately 25% after overlapping. Additionally, the unique sloped lip design enhances the local stability of the flanges, preventing premature buckling under compression.

High Material Utilization Efficiency

- Under the same load-bearing requirements, the weight is 20%-30% lighter compared to a galvanized channel steel of similar specification, reducing the overall building load.Reduces the quantity of purlins and supporting columns required, lowering project costs.

Long-Term Corrosion Protection

- The hot-dip galvanized coating provides comprehensive physical and electrochemical protection. Under standard building envelope conditions, the design service life can exceed 25 years, essentially requiring no maintenance.

High Installation Efficiency

- Factories can perform pre-punching (for mounting holes, grounding holes), notching, and chamfering in advance. No secondary on-site processing is needed; they can be directly connected to roof/wall panels and steel beams using self-drilling screws or bolts.

Galvanized Z-Purlin Customization Services

Wanzhi Group provides full-dimensional customization services covering “section + length + zinc coating + value-added processing”, offering various galvanized section steel solutions for unconventional projects like long-span buildings, heavy-duty PV mounting systems, and uniquely shaped warehouses.

Customization Range

Height: Up to 400mm max (e.g., 400×120×8.0×35).

Flange Width: Up to 150mm max (e.g., 300×150×6.0×30).

Thickness: Standard 2.0-6.0mm, special orders 6.0-10mm.

Lips: Can be customized as unlipped or with unequal lips.

Length Customization: 1-20m cut-to-length.

Zinc Coating Customization: Standard hot-dip galvanizing Z30-Z350 g/m², customizable for coastal/chemical environments.

Value-Added Processing: Pre-punching, web stiffeners, end cutting, welded assemblies.

Factory Strength

Our factory is located in Xingfu Town, Boxing County, Binzhou City, Shandong Province, China, with convenient access to Qingdao Port/Tianjin Port for exports. The factory is equipped with section steel cold-roll forming lines, hot-dip galvanizing lines, and value-added processing lines. It is certified with ISO9001, ISO14001, ISO45001, etc.

Quality Control

Our products comply with international standards such as EN 10219 and ASTM A607. Our factory houses a professional sample room and laboratory equipped with a material testing machine, impact tester, magnetic coating thickness gauge, salt spray test chamber, and laser section measuring instrument. A quality inspection report (including zinc coating thickness, mechanical properties, dimensional deviation data) is provided for each batch.

Delivery Capability

- Stock Availability: Standard specifications (80-250mm height) are available from stock, with delivery in 3-5 days after order confirmation.

- Production Lead Time: Standard production takes 5-15 days; complex customization (large size, value-added processing) takes 15-45 days.

- Logistics Service: Domestic “factory-to-site” direct transportation is supported. For export, we offer CIF/FOB terms, handling customs declaration, inspection, and can assist with overseas warehousing.

Galvanized Z-Purlin vs. Other Section Steels

Galvanized Z-Purlin vs. Galvanized C-Purlin

| Aspect | Galvanized Z-Purlin | Galvanized C-Purlin |

| Cross-Section Shape | Z-shaped | C-shaped |

| Span Capability | Strong (continuous overlap, span 15-20m) | Medium (independent bearing, span 8-12m) |

| Connection Method | Continuous overlapping | Independent installation, requires purlin brackets |

| Bending Performance (Same Weight) | High (section modulus 15%-20% higher than C-purlins) | Medium (slightly lower section modulus) |

| Typical Applications | Long-span buildings (plants, warehouses), PV mounting | Medium/small-span buildings (civil construction, light-duty supports) |

| Material Consumption | Saves Material (uses 10%-15% less material than C-purlins for same span) | More Material (requires more purlins for support) |

Galvanized Z-Purlin vs. Plain Carbon Z-Purlin

| Aspect | Galvanized Z-Purlin | Plain Carbon Z-Purlin |

| Material | Z-section steel as base material | Low-carbon steel (Q235B, Q355B mainstream) as base material |

| Corrosion Resistance | Excellent | Poor |

| Weather Resistance | Excellent | Poor |

| Mechanical Properties | Base steel strength consistent with Z-section steel | Base steel strength: e.g., Q235B yield strength ≥235MPa, tensile strength 370-500MPa |

| Maintenance Cost | Low | High |

| Lifecycle Cost | Low | High |

| Suitable Environments | Outdoor, humid, industrial corrosive environments | Dry indoor, temporary short-term scenarios |

With mature production technology, flexible customization capabilities, and strict quality control, Wanzhi Group can provide customers with full-cycle services, from standard products to special Galvanized Z-Purlin solutions. If you need samples, span/load calculations, quotations for galvanized Z-purlins, or have customization requirements, please feel free to contact Wanzhi Group!