Wanzhi Group operates as a modern coating and galvanizing facility certified under management systems including ISO9001 and ISO14001. We are dedicated to producing high-performance, high-precision galvanized coil, galvanized sheet, and galvanized strip. We provide raw materials and processing services for applications across construction, manufacturing, energy, transportation, agriculture, daily consumer goods, and other sectors.

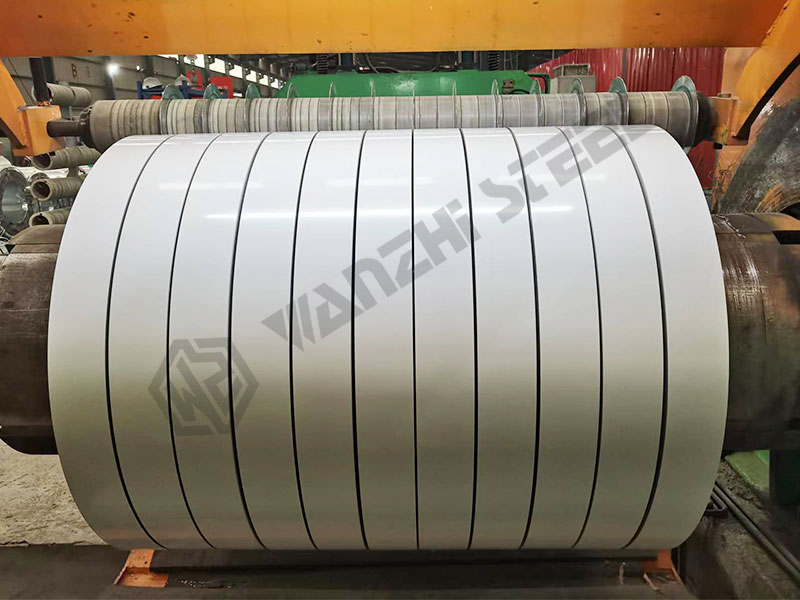

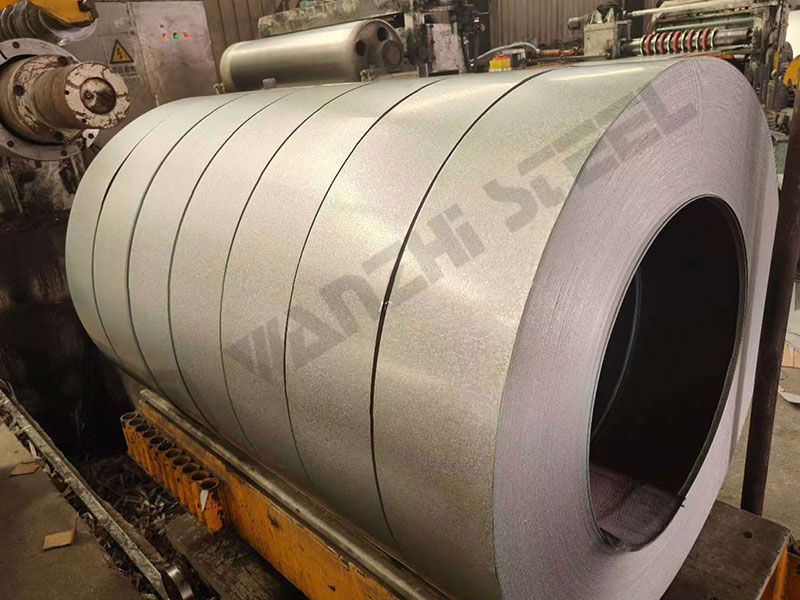

Galvanized Strip for Sale

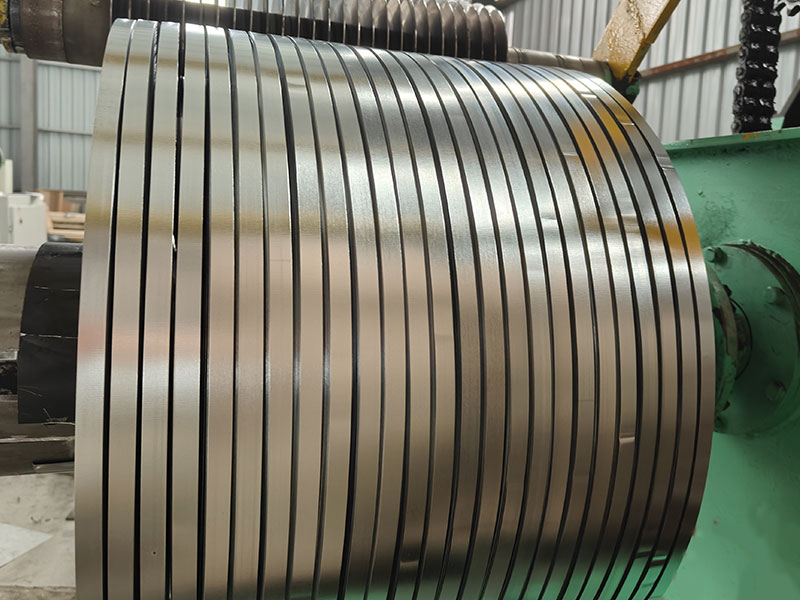

Galvanized steel strip is typically sold in coil form, produced by precision slitting galvanized steel coils. Wanzhi Group manufactures galvanized steel and offers slitting services, capable of processing and producing various specifications according to your requirements.

| Specification | Range |

| Thickness | 0.12-6mm |

| Width | 20mm – 1250mm |

| Length | Customized |

| Status | Coil |

| Coating | Z30-Z350 |

| Substrate | Q195-Q345/SGCC/G30, G60, G90/SGCC, SGCD1, SGCD2, SGCD3, SGC340, SGC400, SGC440/DX51D, DX52D, DX53D, DX54D/DC51D, DC52D, DC53D, DC54D/S220GD, S250GD, S350GD |

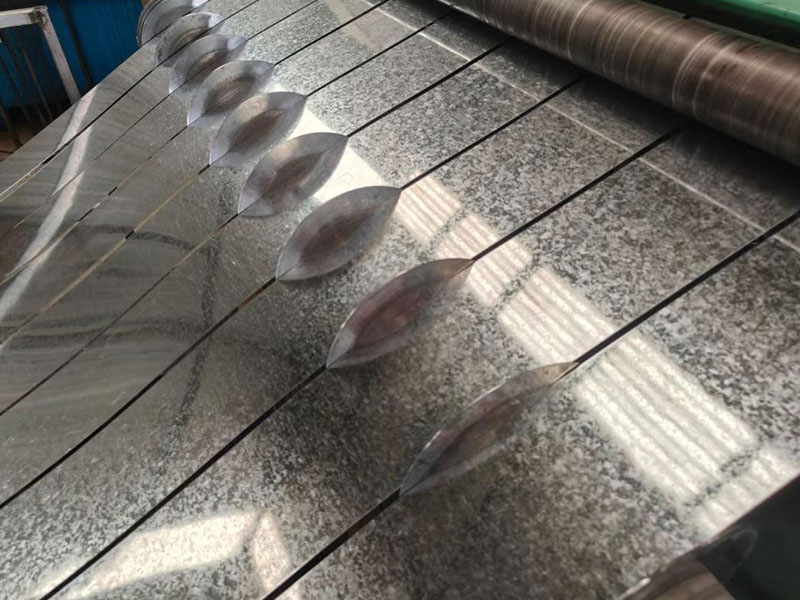

| Surface | Small zinc flower, large zinc flower, regular zinc flower, no zinc flower |

| Treatment | Passivation/oil coating/fingerprint resistant paint/phosphating/painting |

| Packaging | Standard export packaging (plastic film + moisture-proof paper + galvanized steel sheet) |

Product Performance

- Tensile Strength and Yield Strength: The tensile strength of galvanized steel strip ranges from 315 to 600 MPa.

- Elongation: The elongation of galvanized steel strip shall be ≥10%.

- Flatness and Surface Finish: The surface of galvanized steel strip shall be flat and smooth, free from defects such as scratches, pits, or zinc particle accumulation. Oil Film Uniformity: For oiled steel strip, the oil film shall be evenly distributed without dripping or pooling.

- Thickness and Width: Thickness tolerance may be ±0.02 mm, while width tolerance may be ±0.5 mm.

Standard

| Standard System | Typical Standard Number | Coating Representation | Substrate Grade (Example) |

| USA | ASTM A653 | G90 (≈275 g/m²) | CS Type B, SS Grade 33 |

| Europe | EN 10346 | Z275 (275 g/m²) | DX51D+Z, S350GD+Z |

| Japan | JIS G 3302 | Z27 (≈270 g/m²) | SGCC, SGC 340 |

| China | GB/T 2518 | Z275 (275 g/m²) | DX51D+Z, S350GD+Z |

| International | ISO 3575 | – | CR4, SR4 |

Galvanized Strip Coating Composition and Treatment

The coating and surface treatment of galvanized strip determine the physical and chemical properties of the steel. A comprehensive understanding of the coating helps us select more cost-effective strip solutions for projects.

Surface Finish Classification

- No-Spangle: Spangle-free galvanized strip features a uniform, dull surface without crystalline patterns. Its high production cost makes it suitable as a substrate for color-coated galvanized steel.

- Regular Zinc Flowers: Features medium-sized, randomly distributed, flake-like zinc flowers on the surface. These form naturally during the hot-dip galvanizing cooling process. It offers low cost and the widest range of applications.

- Large Zinc Flowers: Features coarse, three-dimensional zinc crystals with pronounced sparkle. Formed during slow cooling after hot-dip galvanizing, it offers aesthetic appeal and excellent decorative properties.

Coating Classification

- Pure Zinc Strip: Manufactured from 99% pure zinc-coated steel, providing fundamental protection in applications. Corrosion resistance is determined by the thickness of the zinc layer.

- Aluminum-zinc coated steel strip: Metal strip produced by adding 55% Al and 1.6% Si to molten zinc before hot-dip galvanizing. Offers 2-6 times the corrosion resistance of galvanized steel and excellent heat resistance.

- Color-Coated Galvanized Steel Strip: Produced by roller-coating organic paint onto galvanized coil before precision slitting. Offers superior corrosion resistance, decorative appeal, and weatherability.

Surface Treatments for Galvanized Steel Strip

- Passivation: Environmentally friendly chromium-free/trivalent chromium passivation primarily prevents white rust and is standard for all galvanized steel.

- Phosphating: Primarily enhances paint adhesion, suitable for galvanized materials requiring painting.

- Oil coating: Works synergistically with passivation to enhance short-term rust prevention.

- Fingerprint-resistant treatment: Primarily elevates product quality, suitable for industrial production in home appliances, electronics, etc.

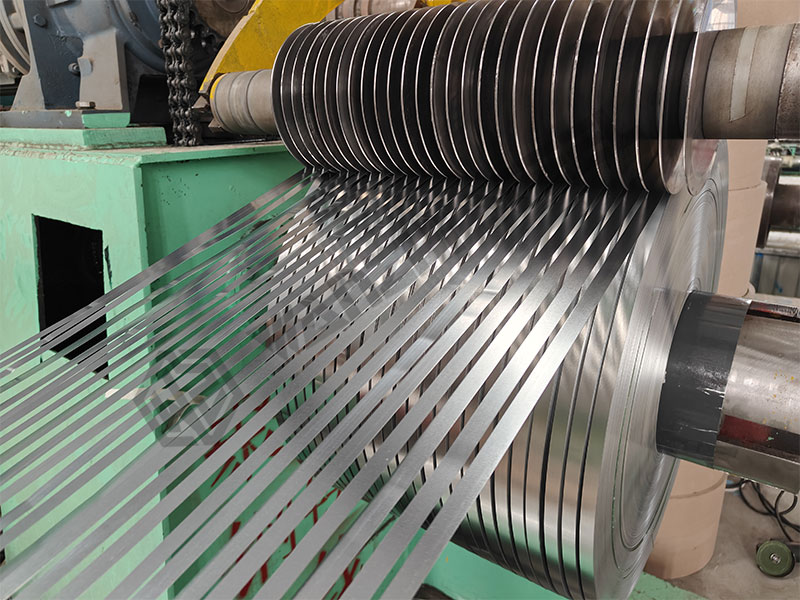

Galvanized Strip Slitting

We possess advanced galvanized strip slitting equipment, offering high-precision slitting services to cut wide coils into specific widths as required by customers.

Galvanized Strip Processing

- Coil Loading and Uncoiling: Galvanized steel coils are hoisted onto the uncoiler to release the strip.

- Straightening: A straightening machine corrects sheet defects such as sickle bend and wave edge formed during coil winding.

- Slitting: The strip is precisely slit into multiple narrow strips by passing through pre-set blades according to the ordered widths.

- Separation and Rewinding: The slit strips are separated and packaged to prevent entanglement or scratches.

- Packaging: Steel straps secure the coils, which are labeled and stored for future use.

Process Requirements

- High-Precision Cutting: Ensures straight edges and burr-free surfaces to prevent edge cracking or jamming during subsequent processing.

- Minimal Tolerance Control: Width tolerances precisely controlled to ±0.1 mm or tighter, meeting stringent demands of precision stamping industries.

- Custom Coil Weight: Tailored inner diameters (e.g., 508mm/610mm) and coil weights to enhance production efficiency.

Galvanized Strip Supplier

We can produce and test according to any major international standard per customer requirements, providing Material Test Certificates (MTC).

OEM ODM

Supply Chain Management: Wanzhi Group strictly controls every step from raw materials to finished products, ensuring consistent quality.

Customization Services: Our engineering team offers material selection guidance, technical consultation, and OEM/ODM customization solutions.

Reliable Supply Capacity: With an annual production capacity of 600,000 tons and lead times ranging from 5 to 45 business days, we guarantee timely delivery to support your production schedules.

Certification Assurance: ISO9001, ISO14001, and other system certifications demonstrate our commitment to consistently delivering compliant products and fulfilling environmental responsibilities.

Packaging

Our Galvanized Strip is packaged according to international standards with moisture-proof and rust-resistant properties to prevent damage during transportation and storage. Packaging materials are labeled with product name, specifications, model, production date, and manufacturer on the outer packaging for traceability and management.

Galvanized Strip Pricing

The price of galvanized strip primarily depends on the zinc coating weight, substrate thickness and grade, surface treatment method, purchase quantity, and current market conditions for zinc ingots and steel. Currently, standard-sized galvanized steel coil is priced between 600-800 USD per ton. Prices for different specifications fluctuate by approximately 50 USD per ton. Contact us for a free quote.

Applications

General hardware components, structural parts, cable trays, standard ventilation ducts, furniture frames, agricultural equipment.

Building roofing/wall systems, automotive exhaust pipes, heat-resistant equipment, coastal construction structures.

Appliance housings (refrigerators, washing machines, air conditioners), interior decoration, office partitions, etc.

We can provide the materials, specifications, and solutions you need—including plain/patterned galvanized strip, color-coated steel strip, stainless steel strip, and more!