Profiled steel cladding refers to formed steel sheets, while architectural cladding systems encompass both wall cladding and roof cladding systems. Typically manufactured from color-coated steel (color-coated galvanized steel and color-coated aluzinc steel), these products combine high-strength steel with premium coatings and forming techniques to enhance both the aesthetics and functionality of buildings.

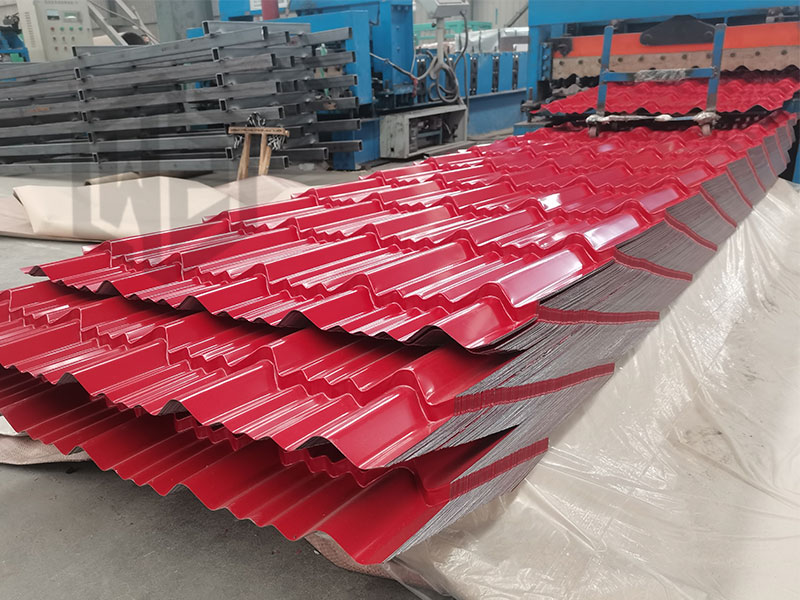

Profiled Steel Roof Cladding

Primarily featuring PPGI roof sheet and PPGL roofing sheet, profiled steel roof cladding serves as the primary waterproof barrier for buildings. It directly withstands harsh conditions like sun exposure, rain, wind, and snow, offering excellent drainage efficiency, corrosion resistance, weather resistance, and decorative appeal.

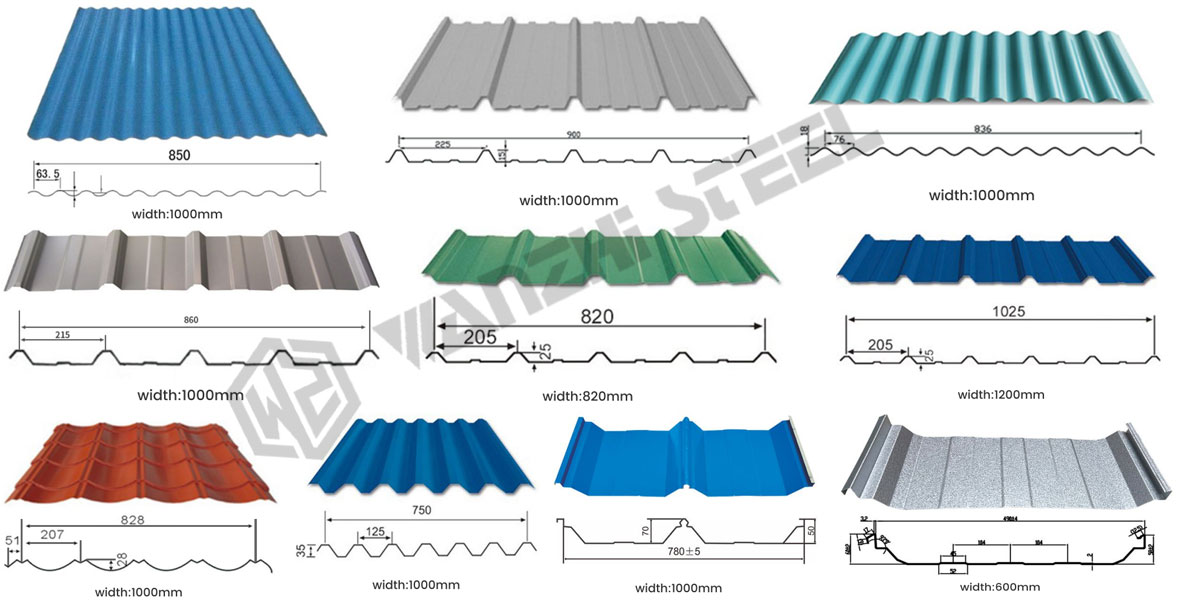

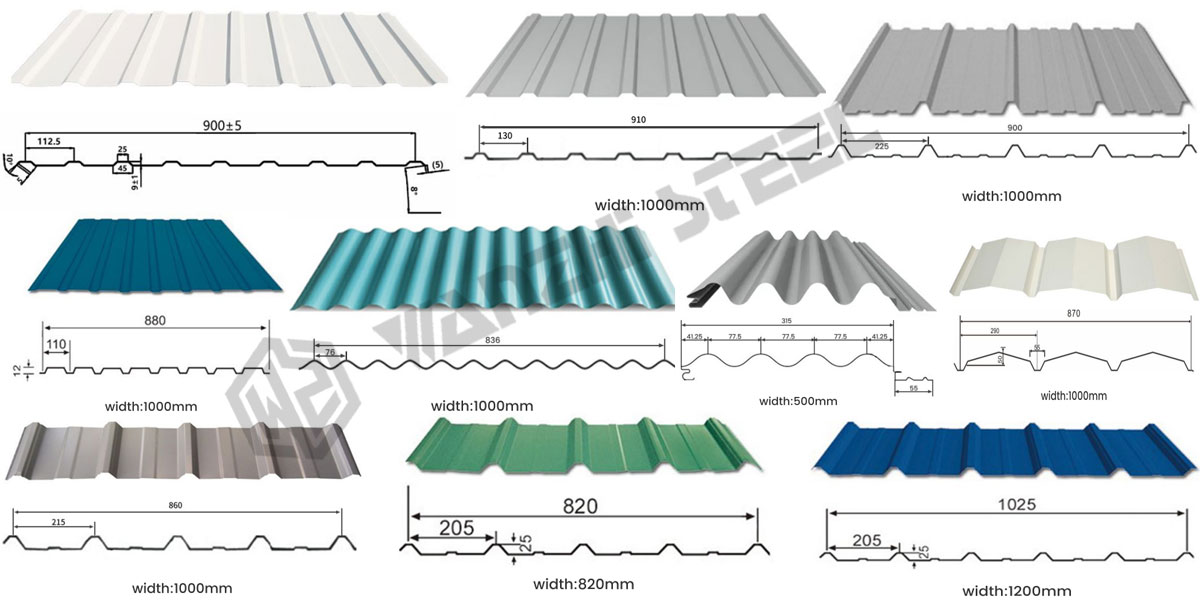

Specifications

- Common thickness: 0.3–0.8 mm. Among these, 0.4 mm, 0.5 mm, and 0.6 mm are the most common specifications, achieving a good balance between cost and strength.

- Common width: 600–1250 mm

Panel Profiles

- Roof panels feature deep profiles for enhanced structural strength, primarily using interlocking or snap-fit connections to withstand loads and pressure. Designs like corrugated, fan-shaped, or tile-imitation panels typically incorporate high ribs and narrow wave spacing to accelerate rainwater drainage and prevent pooling.

Features

- Waterproofing: Tight interlocking systems and efficient drainage ensure leak-free performance.

- High Strength & Rigidity: Despite thin profiles, optimized panel designs deliver exceptional load-bearing capacity.

- Weather Resistance & UV Protection: Surface coatings (e.g., PVDF fluorocarbon) provide long-term resistance to UV exposure and weathering, maintaining vibrant color retention.

- Lightweight and Cost-Effective: Significantly reduces structural load compared to traditional concrete roofs, lowering overall construction costs.

Applications

- Residential and commercial building roofs

- Industrial plants, logistics warehouses

- Large-span structures like stadiums, airports, and train stations

Profiled Steel Cladding for Wall

Profiled steel wall cladding, typically utilizing PPGI and PPGL corrugated and ribbed panels with sufficient rigidity and stability to support building structures, provides weather protection and visual appeal. Wall systems demand higher performance in sound insulation, thermal insulation, fire resistance, and aesthetic decoration.

Specifications

- Common thickness: 0.4–1.2 mm. Thicker panels offer greater wind pressure resistance.

- Common widths: 600–1250mm

Panel Types

- Wall panels are typically installed vertically using bolted fasteners, welding, or simple overlaps. Panel types are diverse, including low-profile corrugated sheets, trapezoidal panels, ribbed sheets, and polyurethane sandwich panels.

Features

- Aesthetic Appeal: Offers diverse colors, coatings, and profiles to accommodate modern, industrial, minimalist, and other architectural styles.

- Flatness: Ensures smooth, clean wall surfaces with superior visual appeal.

- Installation Ease: Forms composite walls with insulation materials for rapid construction.

- Wind Resistance: Withstands high wind loads.

Applications

- Factory and workshop exteriors

- Office buildings and tech park facades

- Shopping mall curtain walls

- Agricultural buildings, cold chain warehouses

Advantages of Profiled Steel Cladding

Superior Corrosion Resistance: Utilizing PPGI/PPGL as base material effectively withstands harsh environments like humidity and acid rain.

Exceptional Weather Resistance: Surface coatings, particularly PVDF (polyvinylidene fluoride), offer outstanding UV resistance with a service life of 15-30 years.

Robust Durability: Formed processing enhances steel sheet strength, structural support, compression resistance, and impact resistance.

Lightweight: Compared to traditional concrete or clay tiles, profiled steel sheets are significantly lighter in weight.

Rapid Installation: Utilizing bolts, self-tapping screws, and other fasteners, factory-prefabricated panels enable direct on-site installation for high efficiency and speed.

Easy Cutting and Processing: Can be easily cut and reworked to fit on-site architectural dimensions.

Low Cost: Low raw material costs, mature manufacturing processes reduce processing expenses, and minimal long-term maintenance costs.

Rich Color Options: Wanhi Group offers any RAL or Pantone color selection, with custom tinting available based on samples.

Diverse Profiles: Multiple styles available including corrugated, fan-shaped, trapezoidal, and tile-imitation.

Excellent fire resistance: Steel is a Class A non-combustible material, meeting most building fire code requirements.

Thermal insulation: Can be combined with materials like glass wool or rock wool to form sandwich panels.

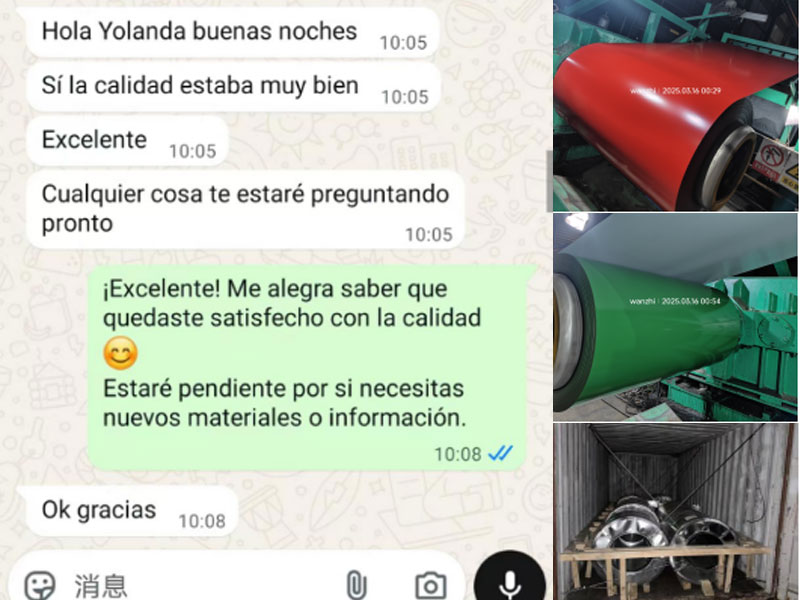

Profiled Steel Cladding Factory

Wanzhi Group Factory is located in Boxing County, Binzhou City, Shandong Province, China. The factory houses processing equipment for profiled steel sheets and sandwich panels, with an annual production capacity of 600,000 tons. Raw materials are also produced in-house, and the facility holds certifications including ISO9001 and ISO14001. If you are seeking raw materials or finished products for your project, please contact us for a complimentary quotation.

Profiled Steel Cladding is a metal material that combines durability, light weight, strength, speed, economy, aesthetics, and environmental friendliness. Whether used as exterior walls or roofing, it is key to the success and longevity of construction projects.