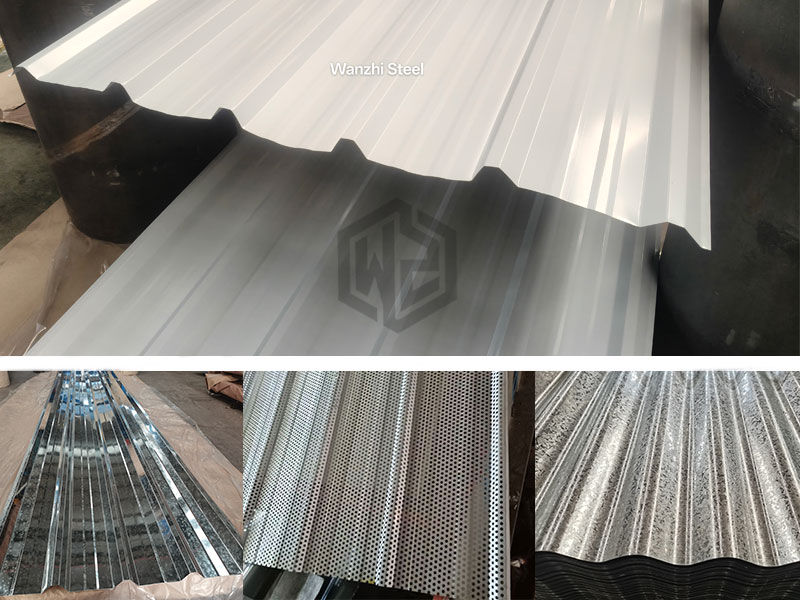

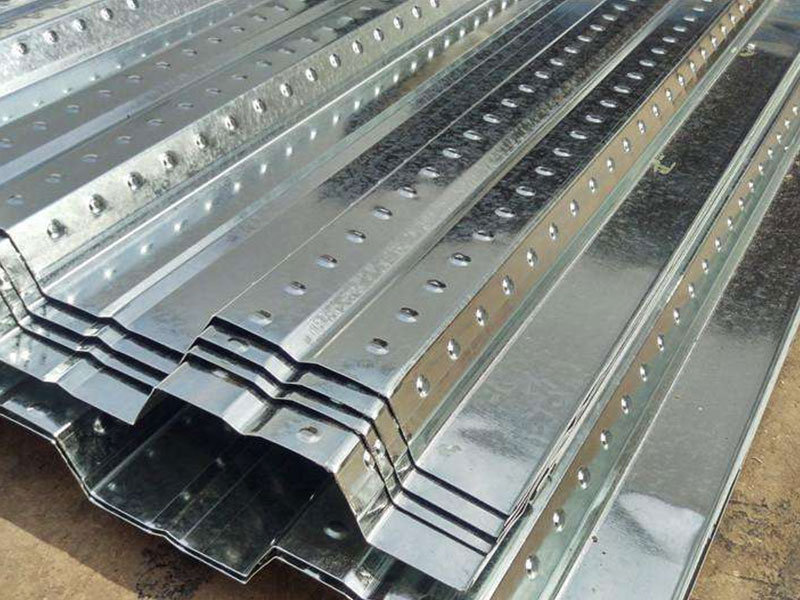

Profiled Steel Sheet Decking, also known as steel decking, is a critical material in the construction industry. Common types include galvanized steel decking and stainless steel decking. Metal decking offers superior load-bearing capacity and deformation resistance, corrosion and fire resistance, efficiency, and safety. It can permanently replace traditional wooden formwork in steel structures, serving as both formwork for pouring concrete slabs and structural reinforcement.

Profiled Steel Sheet Decking For sale

Wanzhi Group provides production and customization services for Profiled Steel Sheet Decking applications in multi-story industrial plants, high-rise office buildings, public structures, and steel-framed residential buildings.

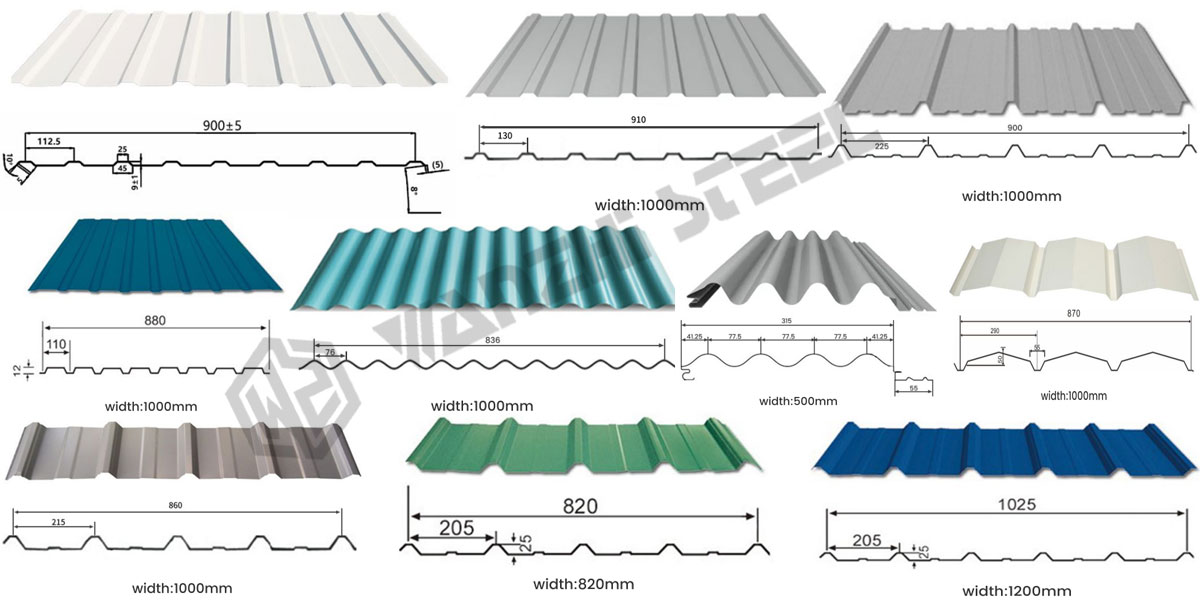

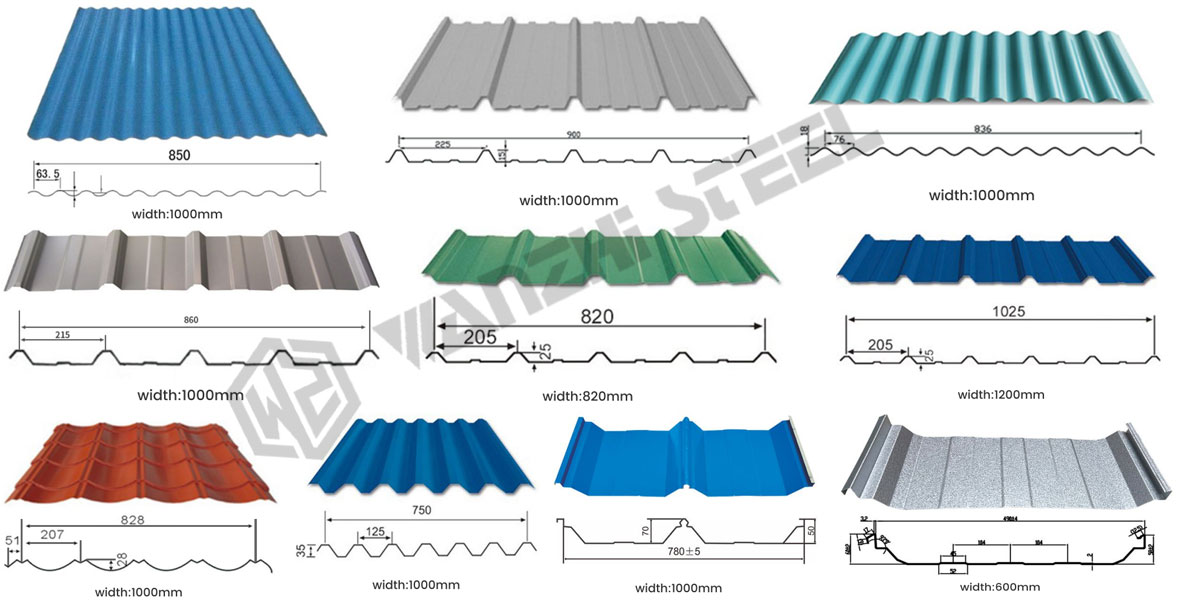

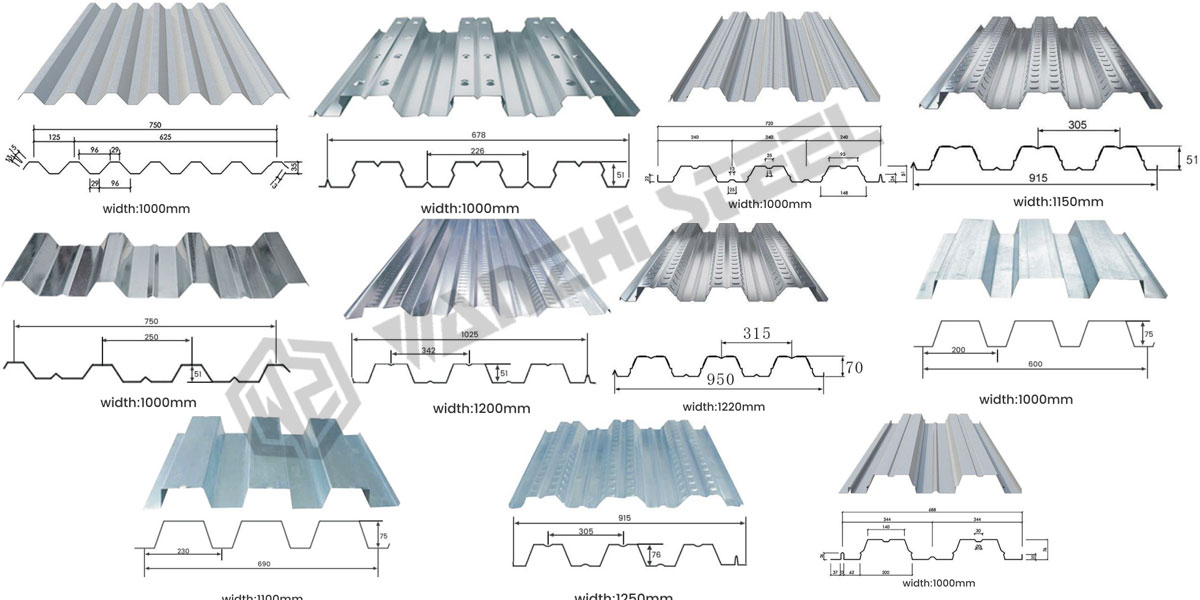

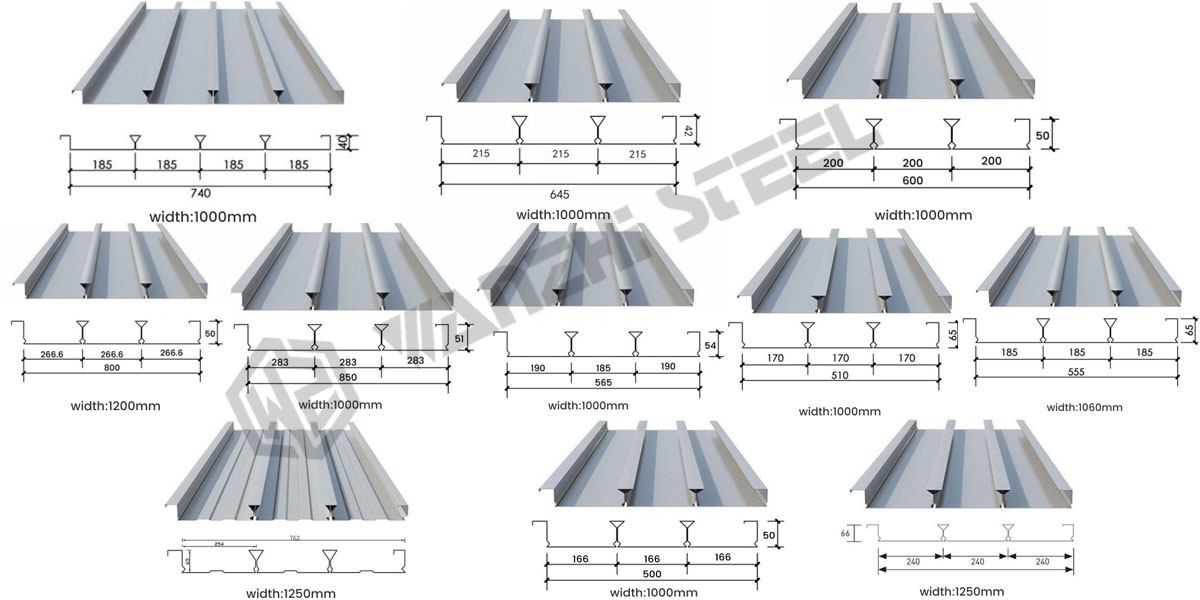

Specifications

Common thickness: 0.8 – 1.2mm. Each 0.1mm increase in thickness boosts flexural strength by 8%.

Flange height: 35-120mm, affecting flexural capacity and concrete bond quality.

Common width: 600–1250mm

Length: Customizable (typically ≤12m)

Materials

Galvanized steel sheet: Cost-effective, suitable for most standard industrial and commercial buildings.

Galvalume steel sheet : Preferred for coastal or chemical plant environments.

Stainless Steel Sheet: For chemical plants or highly corrosive environments with extreme corrosion resistance requirements.

Classification

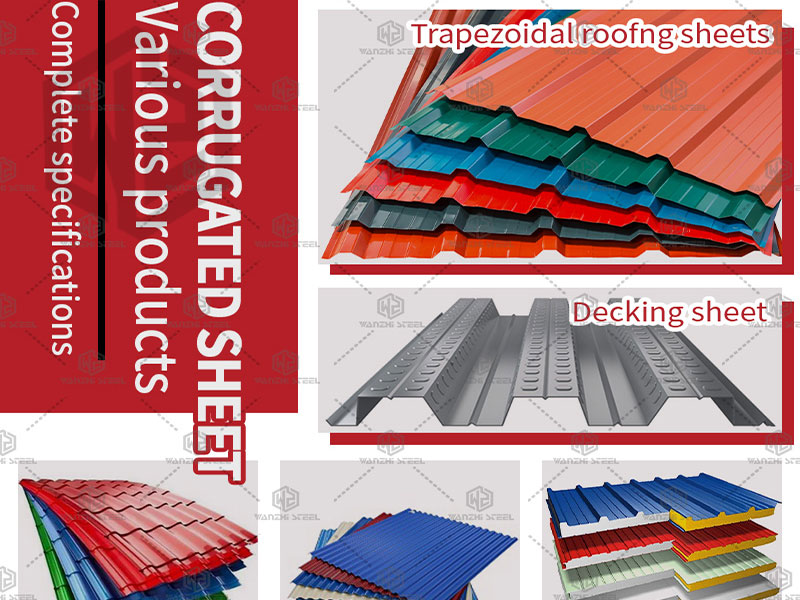

Open-Flange Type: Economical and practical, with strong load-bearing capacity, suitable for small to medium span industrial buildings.

Closed-Flange Type: Fire-resistant properties, with sealed flange bottoms facilitating concealed piping installation, suitable for large span commercial complexes.

Tapered-Flange Type: Combines advantages of open and closed decking, highly economical, and reduces concrete usage.

Panel Characteristics

Compared to standard corrugated sheets, floor decking features a more complex design, delivering exceptional vertical shear resistance.

Increased rib height enhances floor slab rigidity and load-bearing capacity.

Reinforced rib design strengthens the panel’s vertical load-bearing capability and shear resistance.

Special interlocking system ensures tight panel-to-panel connections, improving overall structural integrity.

Features and Applications

Profiled Steel Sheet Decking solutions are widely used in various steel structure buildings. With unmatched construction efficiency, outstanding structural performance, and economic benefits, they serve as an alternative to traditional wooden formwork in construction.

Advantages of Profiled Steel Sheet Decking

Easy Installation: Replacing traditional formwork eliminates the cumbersome processes and material waste associated with formwork erection and removal. It accelerates construction speed and shortens project duration.

Structural Efficiency: Galvanized decking can partially replace structural reinforcement. By welding studs to steel beams, it forms a powerful composite structure that enhances rigidity, strength, and seismic resistance.

Space Optimization: Electrical and communication conduits can be routed within the decking ribs. Integrating structure and piping maximizes clear height.

Safety and Reliability: During construction, the metal decking provides a secure working platform for construction personnel.

Profiled Steel Sheet Decking Applications

Multi-story industrial plants, shopping centers, high-rise office buildings

Logistics warehouses, equipment workshops

Steel-framed residential buildings, apartments, hotels

Public buildings such as hospitals, schools, and gymnasiums

Industrial structures: multi-story factories, etc.

Wanzhi – Profiled Steel Sheets

Wanzhi Group is a factory supplier of profiled steel sheets. We specialize in industrial profiled steel roofing panels, profiled steel wall panels, profiled steel floor decking, and other metal materials for diverse applications. Beyond profiling, we offer comprehensive steel processing services including painting, coating, slitting, and more.