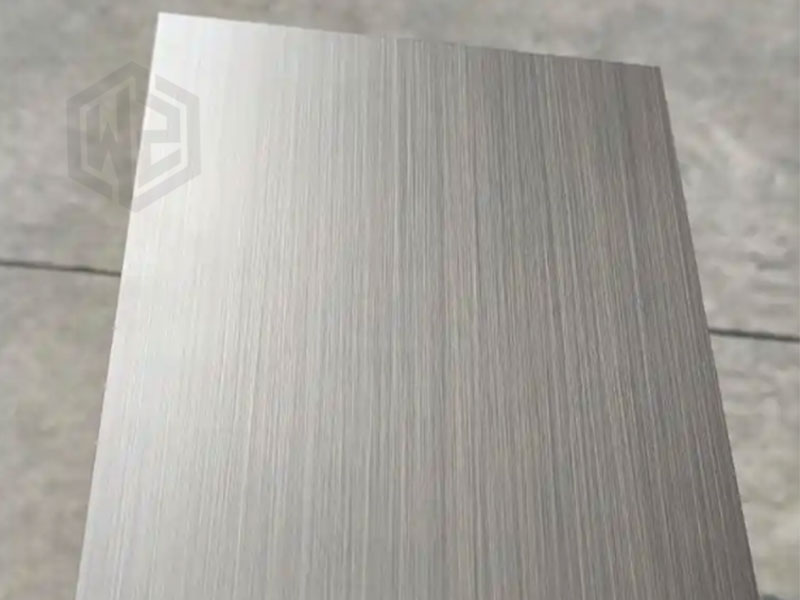

2B Stainless Steel is the most basic and commonly used surface type among stainless steel materials. It features a smooth, flat surface with a slight directional pattern and a soft, reflective silver-white matte finish, making it suitable for subsequent processing such as brushing, polishing, and plating. Wanzhi Group’s 2B finish is applicable to steel grades including 304, 304L, 316, 316L, 430, 410, and 420.

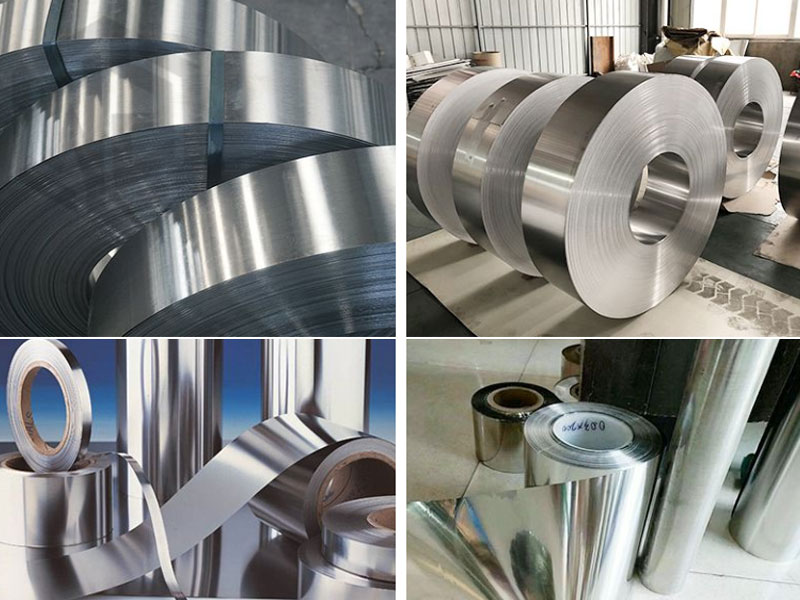

2B Stainless Steel For sale

Wanzhi Group sells various types of cold-rolled stainless steel, including 2B Stainless Steel, 2D, BA, NO.1, NO.4, HL, SB, and more. We provide stainless steel materials that comply with international standards such as ASTM A480, JIS G4305, and EN 10088-2 to customers worldwide. We can provide material certificates, samples, testing, and free quotes.

Specifications

| Item | Product Parameter |

| Product Name | 2B Stainless Steel Coil Plate |

| Thickness | 0.1-300mm or according to customer request |

| Length | According to customer request |

| Width | According to customer request |

| Surface Treatment | 2B |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

| Material Grade | 201, 202, 301, 302, 303, 304, 304L, 316, 430, S30400/S30403, 06Cr19Ni10/022Cr19Ni10, S31600/S31603, 06Cr17Ni12Mo2/022Cr17Ni12Mo2, S43000, 10Cr17, etc. |

| Technique | Cold Rolled, Hot Rolled |

| Application | Food, Natural Gas, Metallurgy, Biotech, Electronics, Chemical, Petroleum, Boilers, Nuclear Energy, Medical, Equipment, Fertilizers, etc. |

Supplier

Wanzhi Group is a steel manufacturer and supplier based in China. We operate seven steel production lines with an annual output exceeding 600,000 tons. Our factory is certified to ISO 9001 and ISO 14001 standards. We supply a wide range of stainless steel products, including stainless steel coils, stainless steel sheets, color-coated stainless steel, stainless steel strips, stainless steel tubes, and other raw materials and finished products in various specifications and grades. Additionally, we offer stainless steel OEM/ODM services, providing cost-effective solutions tailored to specific application requirements.

Pricing

The price of 2B stainless steel is primarily determined by the type of steel grade, with prices ranging from 1,000 to 4,000 USD per ton. Among these, duplex stainless steel is more expensive than austenitic, and martensitic is more expensive than ferritic. Leave us a message with your required steel specifications, dimensions, and material type to receive a free quote!

2B Stainless Steel Production Process

2B refers to the surface finish obtained after cold rolling of stainless steel, followed by annealing, acid washing, and then bright annealing or similar treatment. The surface has a certain degree of luster but is not as bright as BA finish, belonging to the semi-bright category.

- Cold Rolling: Hot-rolled sheets are processed through a rolling mill to achieve the desired thickness and initial surface finish.

- Annealing: The material is heated to high temperatures and then slowly cooled to eliminate internal stresses caused by cold rolling, restoring the stainless steel‘s ductility and mechanical properties.

- Acid Pickling: A mixture of nitric acid and hydrofluoric acid is used to remove residual black oxide scale and impurities from the surface of the annealed stainless steel.

- Flattening/Temper Rolling: Light cold rolling using highly polished rollers to adjust the sheet shape (e.g., eliminating waves or warping) and refine surface roughness, ultimately achieving a 2B surface finish.

Highly Processed Base Material

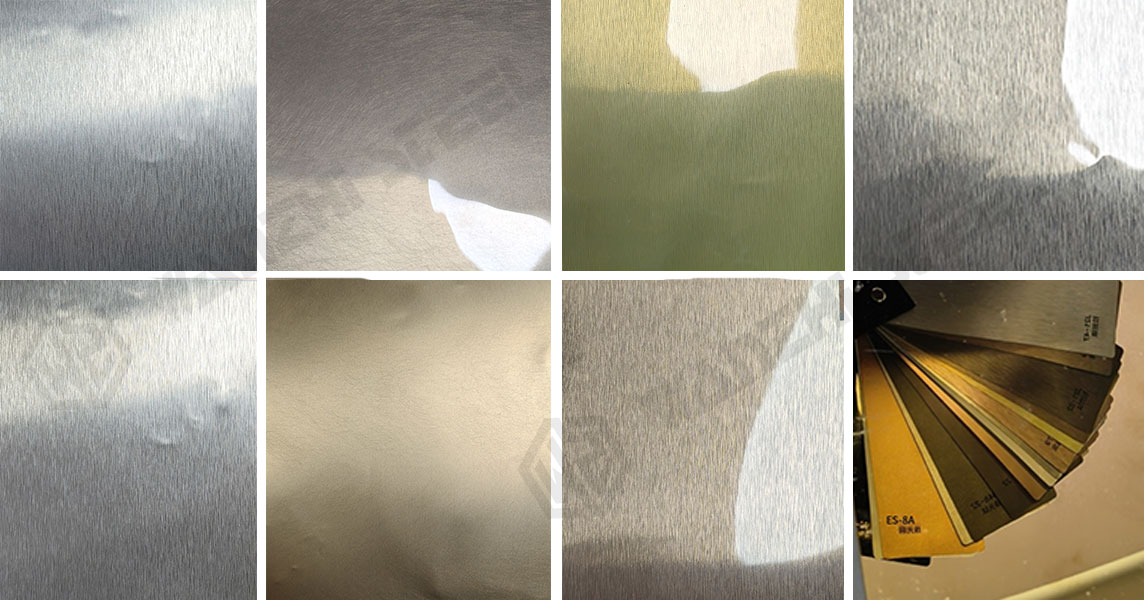

2B stainless steel has a high surface flatness, moderate roughness, and low internal stress, making it an “ideal substrate” for secondary processing such as 8K mirror finishing, polishing, sandblasting, etching, and embossing.

8K mirror finishing

- 2B finish stainless steel can be processed into 8K mirror stainless steel through multiple polishing steps (coarse polishing → medium polishing → fine polishing).

Polishing (non-mirror finish)

- 2B finish stainless steel can be used as a substrate to reduce surface roughness through polishing, creating a surface with higher gloss and texture.

Sandblasting

- 2B stainless steel sheets can be processed into sandblasted stainless steel with anti-slip and decorative effects through high-pressure sandblasting, creating a rough textured surface.

Etching

- 2B finish stainless steel can be selectively etched using chemical solutions (or a combination of masks and solutions) to create patterns, textures, or text on the surface.

Embossing

- Using patterned rollers, 2B SS sheets are rolled under high pressure to create raised or recessed patterns or other textured designs on the surface.

PVD

- In a vacuum environment, physical vapor deposition (PVD) technology is used to deposit an extremely thin layer of metal ceramic coatings such as titanium gold, rose gold, black titanium, or champagne gold onto the surface of 2B finish stainless steel.

2B Stainless Steel Characteristics

2B Stainless Steel Application Scenarios

With the advantages of “moderate cost + flexible processing”, the 2B side is widely used in many industries such as kitchen equipment, home appliances, architectural decoration, and industrial equipment.

- Architectural decoration: elevator interiors, curtain walls, door panels, door frames, baseboards, decorative trim, ceiling panels (requires brushing or plating).

- Home appliances and kitchenware: refrigerator liners, washing machine housings, cabinets, countertops, dishwashers.

- Industrial equipment: chemical containers, pipes, reactors, conveyor covers, storage tanks (corrosion-resistant + easy to weld).

- Household goods: sinks, cookware, hardware accessories (low-cost + easy to process).

- Transportation: interior wall panels, ceilings, luggage racks, etc.

- Structural components and frames: as machine guards, brackets, platforms, stairs.

2D, 2B, and BA Surface Stainless Steel

| eature Dimension | 2D Surface | 2B Surface | BA Surface |

| Finish | Dull Surface | Matte Surface | Bright Surface |

| Process Features | Normal Annealing + Pickling | Normal Annealing + Pickling + Flattening | Bright Annealing |

| Appearance Description | Dull gray-white color, no gloss | Smooth and flat, matte appearance | Extremely smooth and bright, close to mirror effect |

| Gloss (Gs60°) | Very Low | Matte | High |

| Roughness (Ra μm) | Relatively High | Medium | Extremely Low |

| Touch Feel | Rough | Relatively Smooth | Very Smooth |

| Corrosion Resistance | Excellent | Excellent | Good |

| Cost | Low | Medium (Most Cost-Effective) | High |

| Base Material | Ideal for deep stretching processing | Standard material for 8K, sandblasting, etching, etc. | Finished product, or undergo PVD coating |

2B Stainless Steel offers the best balance of corrosion resistance, appearance, workability, cost, and availability. Contact Wanzhi Group for a free quote.