304 stainless steel is the most cost-effective austenitic stainless steel, excellent corrosion resistance, high strength, high temperature resistance and aesthetic properties become one of the indispensable materials in the industrial, food, medical and energy industries. Wanzhi Group is a steel supplier from China, besides 304, 316 austenitic stainless steel, we also provide 430 ferritic stainless steel, 410, 420 martensitic stainless steel, 2205 duplex stainless steel and many other types of steel solutions, contact us for a free quote!

304 Stainless Steel Chemical Properties

304 stainless steel by chromium (Cr), nickel (Ni), carbon (C) and other elements, most of the chemical media (such as acids, alkalis, salts, etc.) has good corrosion resistance, good formability and weldability.

Component

| Element | Content Range |

| Carbon (C) | Max 0.08% |

| Manganese (Mn) | Max 2.00% |

| Silicon (Si) | Max 0.75% |

| Chromium (Cr) | 18.0% – 20.0% |

| Nickel (Ni) | 8.0% – 10.5% |

| Nitrogen (N) | Max 0.10% |

| Phosphorus (P) | Max 0.045% |

| Sulfur (S) | Max 0.03% |

Corrosion Resistance

The protection mechanism of 304 stainless steel relies on a passivation film (Cr₂O₃ dense layer), which is resistant to oxidizing acids and maintains an unchanged appearance.

| Medium | Carbon Steel | Galvanized Steel | 304 Stainless Steel | 316L Stainless Steel |

| Nitric acid (≤65%) | Severe corrosion (>10 mm/y) | Dissolved and ineffective (>20 mm/y) | Excellent (<0.1 mm/y) | Excellent (<0.1 mm/y) |

| Acetic acid (boiling) | Severe corrosion (>15 mm/y) | Moderate corrosion (1 – 2 mm/y) | Good (0.1 – 0.5 mm/y) | Even better (<0.05 mm/y) |

| Chloride solution | Quick rust-through (<1 year) | Sacrificial protection (5 – 30 years). Z60: 5 – 8 years; Z275: >25 years | Risk of pitting corrosion (Cl⁻ > 200 ppm). Pitting corrosion and possible stress corrosion cracking may occur at Cl⁻ > 200 ppm + 50℃ | Resistant to pitting corrosion (Cl⁻ > 1000 ppm) |

| Organic acid (citric acid) | Moderate corrosion (0.5 – 1 mm/y) | Mild corrosion (0.1 – 0.3 mm/y) | Excellent (<0.01 mm/y) | Excellent (<0.01 mm/y) |

| Salt spray environment | Rust-through in 3 months | 500 – 3000 h (determined by zinc layer thickness) | No rust in 1500 h | No rust for >3000 h |

304 Stainless Steel Mechanical Properties

Room Temperature Mechanical Properties

| Performance | Index | Test Standard | Engineering Significance |

| Yield Strength | ≥205 MPa | ASTM E8/E8M | It represents the lower limit of structural load-bearing capacity. |

| Tensile Strength | ≥515 MPa | ASTM E8/E8M | It reflects the material’s ability to resist fracture. |

| Elongation | ≥40% | ASTM E8/E8M | It indicates the margin for forming and processing. |

| Hardness | ≤92 HRB | ASTM E18 | It is related to the material’s machinability. |

Low/high Temperature Performance

| Temperature | Impact Toughness (J) | Strength Change | Recommendations for Use |

| -196°C | >100 (austenite stabilized) | Strength increases by 30% | Applicable for liquid nitrogen containers |

| 540°C | – | Yield strength decreases to 120 MPa | Time-limited use (<1000h) |

| 800°C | – | Oxidation rate increases dramatically | Prohibition of long-term use |

304 Stainless Steel Surface Finish

Industrial grade surface (ISO 9444)

| Type | Roughness (Ra) | Process | Characteristics |

| 2B Surface | 0.1 – 0.5μm | Cold rolling + bright annealing + passivation | The surface appears silver-white with relatively low glossiness |

| BA Mirror Surface | ≤0.05μm | Annealing in a protective atmosphere + polishing | Has high reflectivity |

| Brushed Surface | 0.4 – 0.8μm | Mechanical grinding with directional patterns | The surface has uniform, fine textures |

| Sandblasted Surface | 35~75μm | High-speed jet spraying with a spray gun | Has a uniform matte effect |

Surface Treatment Technology

Electrolytic polishing: removal of surface ferrite, corrosion resistance increased by 30

Passivation: Nitric acid + dichromate solution, Cr/Fe ratio >1.5

PVD coating: TiN layer (gold color), hardness up to 2000HV

Stainless Steel Grades Comparison Table

The grades of 304 stainless steel can vary according to different standards, but its main types are AISI 304, EN 1.4301, JIS SUS304, and so on.

| Standard System | Grade | Correspondence | Key Differences |

| Chinese GB | 06Cr19Ni10 | Equivalent to 304 | Carbon (C) content ≤ 0.08% |

| American ASTM | S30400 | Basic 304 | No special requirements |

| European EN | 1.4301 | Strictly equivalent to 304 | Copper (Cu) content ≤ 1.0% |

| Japanese JIS | SUS304 | General industrial type | Phosphorus (P) content ≤ 0.045% |

| Special Variant | 304L | Ultra-low carbon (C ≤ 0.03%) | Prevents intergranular corrosion during welding |

304 Stainless Steel Advantages and Application Scenarios

304 stainless steel has become an irreplaceable metal material in the food and industrial sectors because of its diverse surfaces and cost-effective price.

Advantages

- Low cost, compared with other materials of stainless steel, 304 grade stainless steel price is low, long life cycle, low maintenance costs.

- Hygiene and safety, microbial adhesion rate <5%.

- All-round corrosion resistance, can resist nitric acid / organic acids and other substances corrosion.

- Excellent processability, elongation > 40%, hardness ≤ 92HRB, can be complex molding process.

- High-temperature oxidation resistance: in high-temperature environment, 304 ss has excellent oxidation resistance.

- Recyclable, the recycling rate of stainless steel is more than 92%.

- Diversified surfaces, metal color + brushed/BA mirror/embossed and other customized surfaces.

Application Scenarios and Selection Guide

Chemical industry

- Application: reactor, piping, storage tanks

- Recommended: 304 2B surface stainless steel, 316L cost

Food Machinery

- Applications: Filling lines, work benches, water storage tanks, refrigeration equipment

- Recommended: 304 BA mirror stainless steel

Architectural Decoration

- Application: curtain wall, handrail, elevator car, art sculpture, balcony railing

- Recommended: 304 brushed surface (8K) stainless steel

Medical equipment

- Application: surgical instrument table

- Recommended: 304L electrolytic polishing

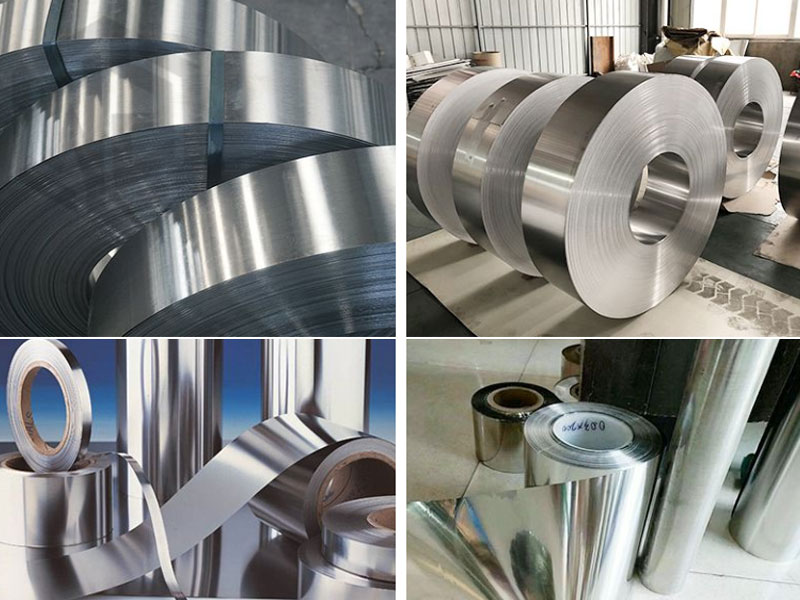

New Energy and Transportation

- Applications: fuel cell bipolar plates, process gas piping, compartment structure skeleton, automotive exhaust systems, automotive parts

- Recommended: 304 ultra-thin strip

304,316L,2205 SS Material Comparison

| Material | Cost Index | Resistance to Cl⁻ Corrosion | Weldability |

| 304 Stainless Steel | 100% | General | Excellent |

| 316L Stainless Steel | 150% | Good | Good |

| 2205 Duplex Steel | 180% | Excellent | Difficult |

| Carbon Steel + Rubber Lining | 70% | Poor | Simple |

Stainless Steel Supplier

Wanzhi Group is a stainless steel supplier from China, besides 304 stainless steel, we also provide OEM,ODM service for 316,430,2205 stainless steel, we have slitting, bending, forming, plating and other processing lines, the factory is certified by ISO9001,ISO14001 and so on. If you are looking for cost-effective steel solution, or coated steel, alloy steel factory supplier, welcome to contact us!