316 stainless steel is an austenitic stainless steel containing molybdenum (Mo), which significantly improves chloride corrosion resistance on the basis of 304 and is widely used in highly corrosive environments such as marine, chemical, medical, etc.As a steel supplier in China, Wanzhi Group provides solutions for many types of stainless steel such as 304, 430, 2205,etc., in addition to 316, please feel free to contact us for a free quote!

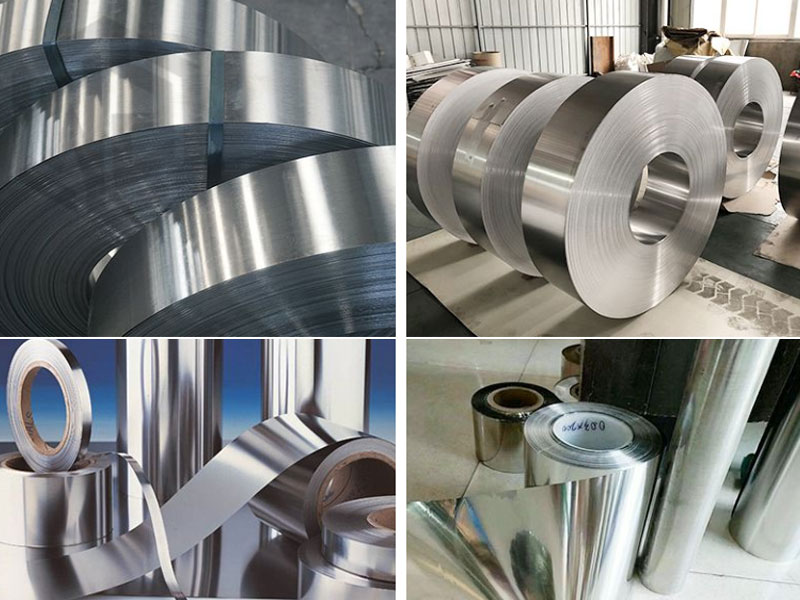

Wanzhi – 316 Stainless Steel

Wanzhi Group is a stainless steel factory supplier in China, we supply many kinds of austenitic stainless steel, including 304 stainless steel, 316 stainless steel, 321 stainless steel, 310 stainless steel, 309 stainless steel and so on.

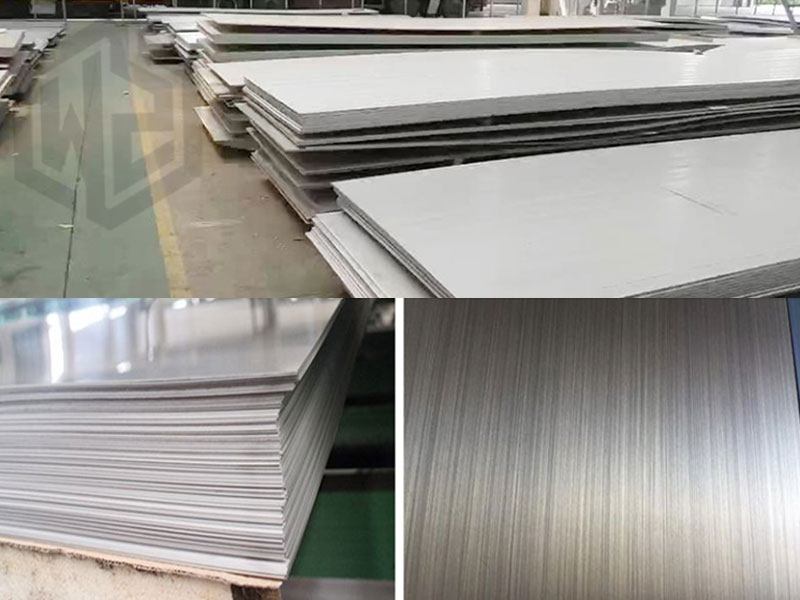

| Product Form | Specification Range |

| Material | 316, 316L (extra low carbon), 316H (high temperature type) |

| Sheet/Coil | Thickness 0.1-120mm, Width ≤2000mm |

| Pipe | Ø6-630mm (Welded pipe/Seamless pipe) / Thin-walled precision tube (Wall thickness 0.5mm ± 0.05) |

| Bar | Ø5-300mm (Hot-rolled/Cold-drawn) |

Chemical composition

316 ss In addition to chromium (Cr) and nickel (Ni) as the main alloying elements, 2-3% molybdenum (Mo) is added to form a stronger passivation film, which significantly enhances the resistance to pitting/crevice corrosion.

| Element | Content Range |

| Carbon (C) | ≤0.08% |

| Chromium (Cr) | 16.0-18.0% |

| Molybdenum (Mo) | 2.0-3.0% |

| Nickel (Ni) | 10.0-14.0% |

| Manganese (Mn) | ≤2.00% |

| Silicon (Si) | ≤0.75% |

| Nitrogen (N) | ≤0.10% |

Corrosion Resistance

| Medium | 316 Stainless Steel |

| Chloride Solution | Pitting corrosion resistant (Cl⁻ > 1000ppm) |

| Seawater Environment | Long-term corrosion resistance (>25 years) |

| Sulfuric Acid (10%) | Corrosion rate < 0.1 mm/y |

| Salt Spray Test | 3000+ hours without rust |

Mechanical Property

| Property | Value |

| Yield Strength | ≥205 MPa |

| Tensile Strength | ≥515 MPa |

| Elongation | ≥40% |

| Hardness | ≤95 HRB |

International Standard

| Standard System | Grade | Key Differences |

| China GB | 06Cr17Ni12Mo2 | Molybdenum content ≥ 2.0% |

| USA ASTM | S31600 | Basic type 316 |

| Europe EN | 1.4401 | Minimum Nickel content 12% |

| Japan JIS | SUS316 | Phosphorus content ≤ 0.045% |

| Extra low carbon variant | 316L | Carbon ≤ 0.03% (Welded for intergranular corrosion resistance) |

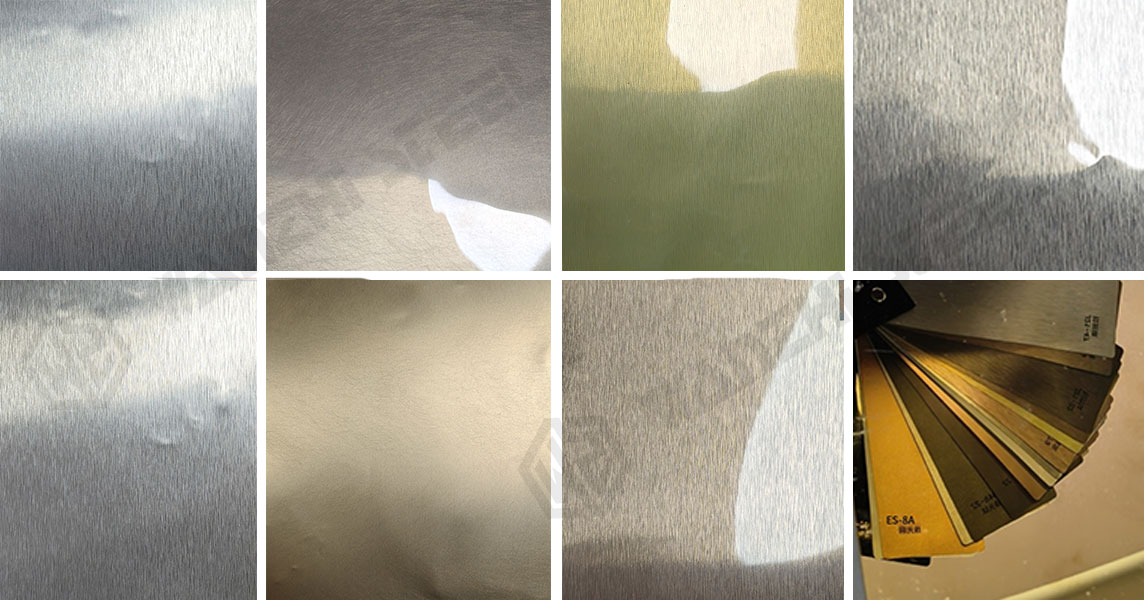

Surface Treatment Process

Electrolytic polishing + passivation of 316 is better:

- BA mirror surface (≤0.05μm): medical equipment, food machinery

- Brushed surface (0.4-0.8μm): ship decoration, building components

- Sandblasted surface (35-75μm): chemical valves, marine platforms

Core Advantages and Application Scenarios

316 stainless steel has become an important material for many industries such as construction, chemical, food, pharmaceutical, medical, energy, marine and so on due to its strong corrosion resistance, high temperature resistance, good mechanical properties, abrasion resistance and medical grade safety and hygiene properties.

Advantages – 316 Stainless Steel

- Excellent corrosion resistance: Resistant to chloride, seawater and brine, sulfuric acid, hydrochloric acid, hydrofluoric acid corrosion, corrosion rate is 50% lower than 304.

- Excellent high temperature resistance: continuous oxidation resistance below 870℃, at low temperatures, it still maintains good toughness and is not easy to be brittle.

- Good mechanical properties: used in complex shapes of welded joints.

- Good abrasion resistance: Resistant to a certain degree of abrasion, suitable for applications with high friction.

- Medical grade safety: ISO 13485 certified, microbial adsorption rate <3%, the surface is not easy to accumulate dirt and microorganisms, easy to clean and disinfect.

Typical applications – 316 Stainless Steel

- Building decoration: decorative or structural materials such as building facades, railings, door and window frames, etc.

- Marine engineering: marine valves, seawater pipelines, vessels, seawater treatment equipment, ocean engineering equipment

- Chemical equipment: reactors, acid storage tanks, piping systems, heat exchangers, and other equipment

- Medical equipment: surgical instruments, implant carriers (e.g., artificial joints, bone nails, etc.))

- Energy and environmental protection: flue gas desulphurization devices, nuclear power pipelines

- Food and pharmaceuticals: equipment and containers for the dairy, beverage and pharmaceutical industries (aseptic production lines)

- Daily necessities: high-quality kitchen knives, stainless steel pots and pans, earrings, necklaces, etc.

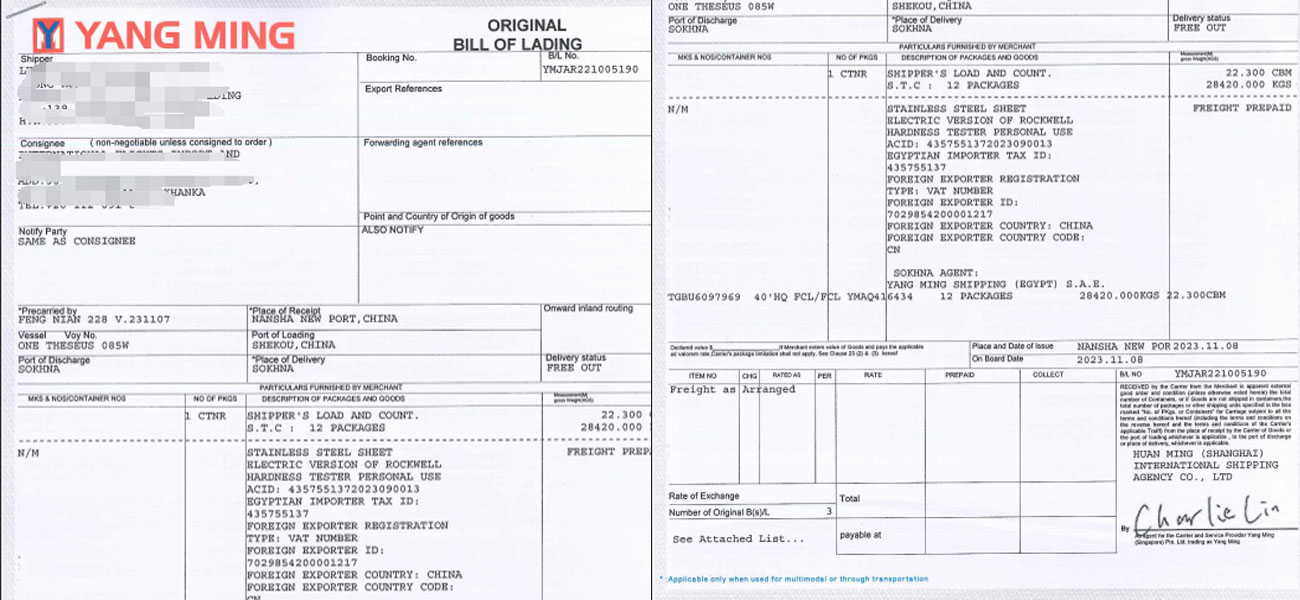

Wanzhi Group Service

Zhengzhou Wanzhi Steel Materials is certified by ISO 9001:2015, ISO 14001, etc. We not only have professional roll mills, stainless steel production line (thickness tolerance ±0.01mm), but also have the testing capacity of direct reading spectrometer/OES testing, etc. If you are looking for a steel supplier, or you are looking for a solution for your project, please feel free to contact us. If you are looking for a steel supplier, or selecting a solution for your project, please feel free to contact us.

316 Stainless Steel Factory

Our factory not only supply all kinds of stainless steel sheets, coils, strips and tubes, we also have stainless steel precision parts/structural parts/stamping parts machining service and stainless steel electrolytic polishing, PVD coating, brushing surface treatment.

316 Stainless Steel OEM ODM

Wanzhi Group provides stainless steel OEM to specified specifications and ODM innovative partnership services.

- Quick quote: 2 hours

- Sampling service: 5-7 days

- Small batch trial production: 15 days

- Rush order: 5-7 days

Project Examples

So far, we have provided steel solutions for offshore anti-corrosion projects, tool production, construction material processing and other applications.

Industry customized solutions

Marine engineering anti-corrosion

Requirement: Solve seawater Cl- corrosion + bio-adhesion problem

Solution:

- 316L substrate (Mo≥2.5%)

- Super-hydrophobic nano-coating (contact angle>150°)

- Cathodic protection system design

Chemical Pressure Vessel Integration

Requirements: High Temperature Resistance + Chemical Corrosion Resistance

Solutions:

- 316H (High Temperature Creep Resistance)

- TIG + Backside Argon Protection

Food Engineering

Requirements: corrosion resistance + antimicrobial resistance + easy cleaning

Solutions:

- Tank: 316L electrolytically polished (Ra = 0.08 μm)

- Pipes: EP-grade clean polished (Ra ≤ 0.15 μm inside)

In addition to austenitic 316 stainless steel, Wanzhi Group also has ferritic stainless steel, ferrite stainless steel, martensitic stainless steel, duplex stainless steel, precipitation hardening stainless steel,galvanized steel and so on, what specifications and types of steel you need, leave a message to get a free quote!