Wanzhi Group, a brushed stainless steel supplier, specializes in high-quality 201, 430, 304, and 316 stainless steel with brushed, snowflake, and other finishes. We offer stainless steel OEM/ODM services for applications in architecture, home appliances, and decoration.

Brushed Stainless Steel for Sale

Wanzhi Group offers stainless steel in a variety of standard specifications and finishes, as well as customized special stainless steel services. We offer a wide variety of stainless steel types, including austenitic, ferritic, martensitic, duplex, and precipitation-hardening stainless steels. Please leave a message to share your requirements and receive a free quote.

| Parameter | Specification | Common Values |

| Material Grades | 304 / 304L | Commonly used material, good corrosion resistance, heat resistance, and machinability. |

| 316 / 316L | Contains molybdenum, higher cost, stronger pitting resistance. | |

| 201 | Contains manganese and nitrogen, partially replacing nickel, lower cost, average corrosion resistance. | |

| 430 Stainless Steel | Ferritic stainless steel, suitable for environments with slightly higher corrosion and heat resistance requirements, with moderate strength. | |

| Mechanical Properties | Yield Strength (Rp0.2) | ≥205 MPa (304) |

| Tensile Strength (Rm) | ≥515 MPa (304) | |

| Elongation (A) | ≥40% (304) | |

| Hardness | Typically HV150-200 (annealed state), surface hardness slightly altered by brushing process. | |

| Physical Properties | Density | About 7.93 g/cm³ (304) |

| Surface Hardness | HV150-200 (annealed state), surface hardness slightly altered by brushing process. |

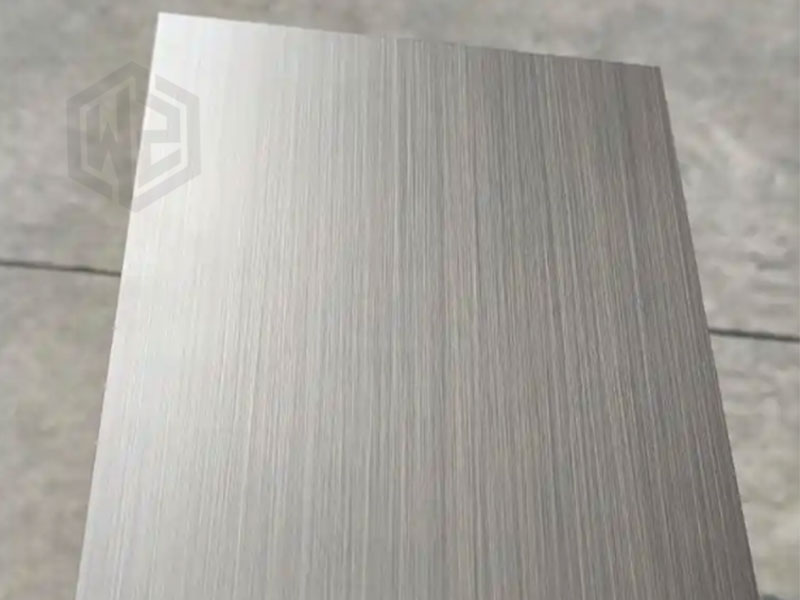

Brushed Stainless Steel Texture

Brushed stainless steel features a regular linear pattern created on the surface of stainless steel through mechanical processing. These patterns diffusely reflect light, creating a soft, subdued metallic luster, avoiding the glare and fingerprint-prone nature of mirror-finished stainless steel.

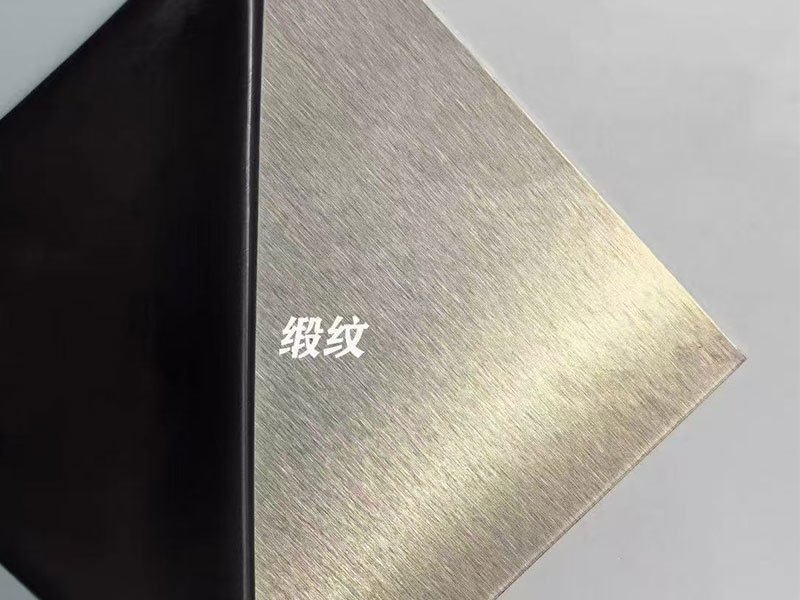

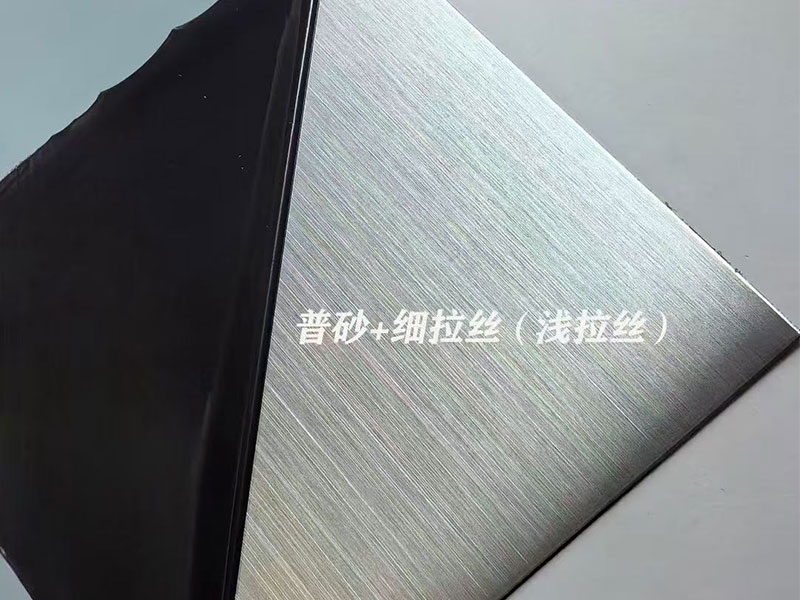

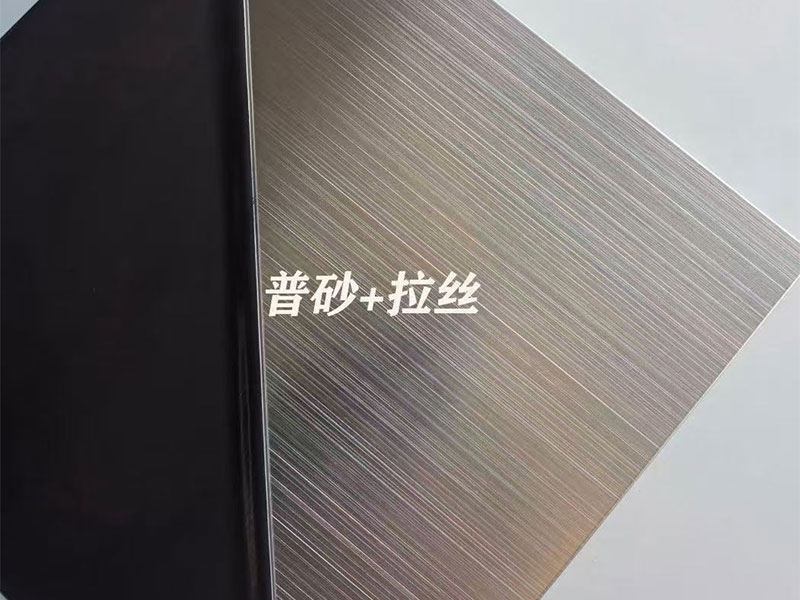

- Straight (Hairline) Texture: This is the most common pattern, with straight, continuous lines like hair, creating a simple, flowing appearance.

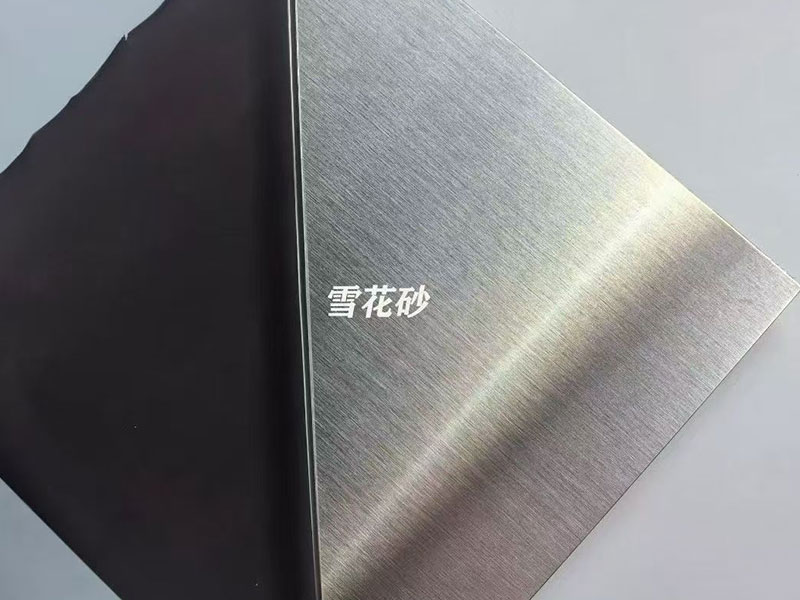

- Snowflake Texture: Irregular lines, resembling snowflakes or tangled strands, offer a more refined feel and effectively conceal minor scratches.

- Random Texture: Irregular, chaotic lines, interlaced in swirling or arc-like patterns, offer a strong decorative effect.

- Wave Texture: Rippled lines undulate like ripples, creating a dynamic effect and are often used in more decorative applications.

- Nylon Texture: Created through a nylon brush, the texture is delicate and suitable for high-end decoration.

Brushed Stainless Steel Process

Brushed stainless steel features a regular or irregular, filamentous pattern created on the surface by physical friction. Common processing methods include mechanical and manual drawing. Mechanical drawing is currently the mainstream method due to its high efficiency and low cost.

Process Flow

- Pretreatment: Degrease, pickle, rinse, and dry the stainless steel material to ensure a clean, oil-free surface.

- Brushing: Select tools and drawing pressure based on the customer’s desired finish.

- Polishing: Improves the surface finish and gloss of the steel, enhancing its texture.

- Lamination: Prevents oxidation and scratches on the stainless steel surface.

Processing Methods

- Mechanical Brushing: A brushing machine equipped with a nylon wheel, abrasive belt, or stainless steel wire brush rubs the stainless steel surface with a constant linear or rotary motion under pressure to create a uniform pattern.

- Chemical Brushing: A chemical etchant reacts with the stainless steel surface to etch the desired texture (used for complex shapes).

- Sandblasting: Sandblasting is performed to create a matte finish before brushing, resulting in a unique, complex texture.

Features of Brushed Stainless Steel

Aesthetics: Unique textured surface for a premium feel

Wear-Resistant: The brushed surface effectively conceals minor scratches incurred during production, transportation, and use

Easy to Clean: The matte finish resists fingerprints and is easy to clean.

Durable: Retains stainless steel’s excellent properties, including corrosion resistance, rust resistance, high-temperature resistance, and high strength.

Versatile: Suitable for a variety of design styles, including modern minimalist, industrial, and affordable luxury.

Applications of Brushed Stainless Steel

Architectural Decoration: Elevator cabs, hall doors, railings, stair railings, accent walls, door and window frames, signage, etc.

Home Appliances: Panels for refrigerators, range hoods, ovens, disinfection cabinets, and housings for microwave ovens and water heaters.

Kitchen and Bathroom Supplies: Sinks, faucets, kitchenware, countertops, and hardware accessories.

Consumer Electronics: Smartphone midframes, laptop cases, and smartwatch cases.

Public Transportation: Interior trim, interior components, wheels, and door handles for subway and high-speed rail carriages. Furniture and Home Furnishings: Dining tables, coffee tables, cabinets, lamps, shelves, etc.

Medical Devices: Manufacturing of some medical equipment.

Industrial Sector: Industrial equipment and devices with certain aesthetic requirements.

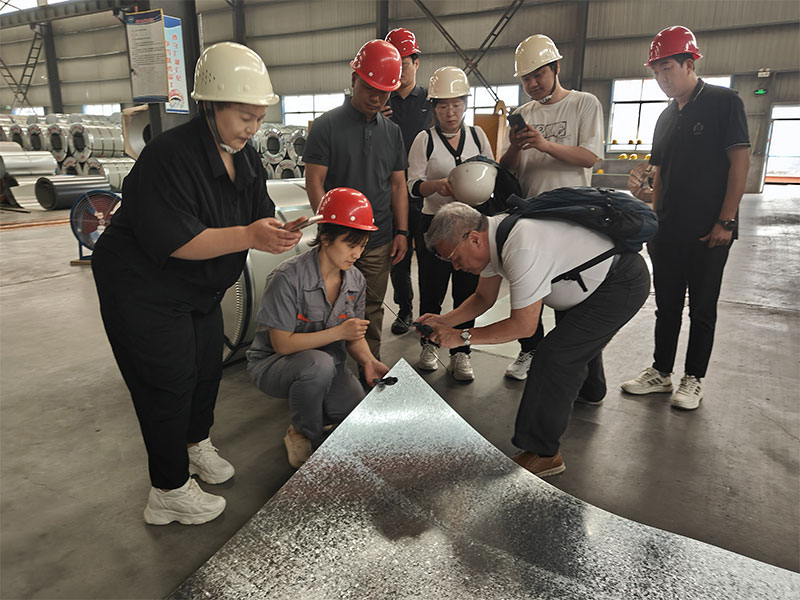

Brushed Stainless Steel Factory Supplier

Wanzhi Group is a stainless steel supplier from China. Our stainless steel products, including 2B stainless steel, 8K stainless steel, BA stainless steel, brushed stainless steel, stainless steel pipes, and more, have been exported to over 100 countries and regions worldwide, including Russia, Indonesia, Turkmenistan, Iran, and Brazil.

Wanzhi Factory Advantages

Quality Assurance: Raw materials are sourced from renowned domestic steel mills, and the quality of the stainless steel substrate is strictly controlled from the source, ensuring the quality of the finished brushed products.

Cost Control: Factory wholesale pricing provides customers with the best cost solutions.

Custom Finished Product: We offer a variety of widths and thicknesses, as well as custom surface textures.

Precision Control: We can precisely control surface roughness (Ra value) and gloss (GU value) to ensure consistency across batches.

Quality Control: From raw material warehousing, through the production process, to finished product shipment, a professional team conducts quality inspections.

One-Stop Service: We offer slitting, cutting, laser cutting, bending, welding, sheet metal processing, and other follow-up services.

Wanzhi Product Packaging

Wanzhi Customer Feedback

If you’re looking for stainless steel production and processing with brushed, bright annealed, or mirror finishes, please contact us. We offer a variety of stainless steel finishes in coils, sheets, tubes, and strips.