NO.1 Finish Stainless Steel, hot-rolled stainless steel, is the most basic and original industrial surface state of stainless steel. It has excellent machinability and a matte off-white surface. It can be stamped, stretched, or polished. As an industrial raw material with extremely high cost-effectiveness, it is widely used in the stainless steel “deep processing” market.

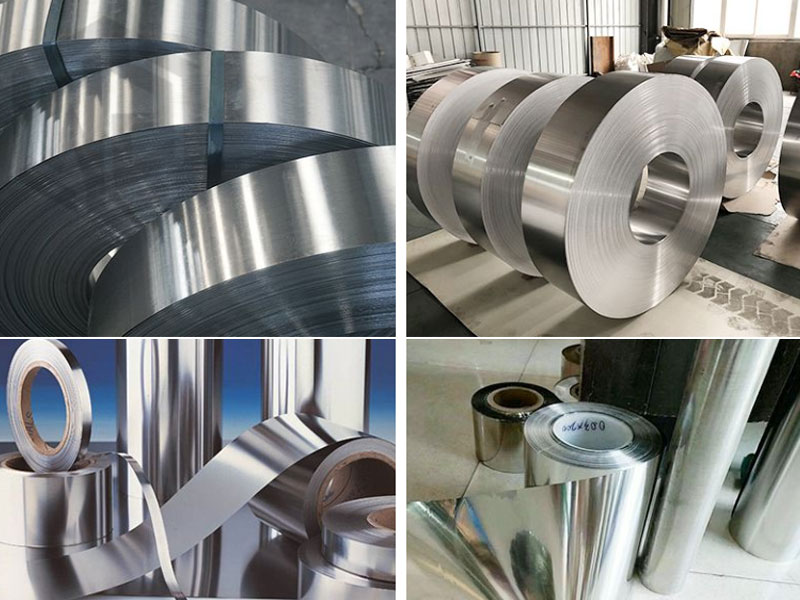

NO.1 Finish Stainless Steel for Sale

Wanzhi Group sells various types of stainless steel raw materials and costs, including NO.1 Finish Stainless Steel, 2B Stainless Steel, 8K Stainless Steel, HL Stainless Steel, etc.

Specification

| Parameter | Range |

| Grade | 304 / 1.4301, 304L / 1.4307, 316 / 1.4401 |

| Thickness | 2.0–10.0mm (standard), customizable up to 150mm (thick plates) |

| Width | 1000–2000mm (standard), extendable up to 2500mm (wide width) |

| Length | 2000–6000mm (standard), can be coil-wound (steel coil) or cut-to-length (flat plate) |

| Thickness Tolerance | ±0.10mm – ±0.20mm |

| Width Tolerance | +6 / -0 mm |

| Flatness Tolerance | +6 / -0 mm |

| Standards | ASTM A480/A480M, EN 10088-2, JIS G4305 |

| Mechanical Properties | Yield Strength ≥ 205 MPa, Tensile Strength ≥ 515 MPa, Elongation ≥ 40% (per ASTM A240) |

Comparison with Other Common Surfaces

| Surface Code | Name | Process | Appearance |

| NO.1 / 1D | Hot Rolled Annealed, Pickled | Non-glossy, gray-white, rough | Industrial deep processing, polishing blanks |

| 2B | Cold Rolled Annealed, Pickled, Flattened | Silver-white, slight gloss, relatively smooth | Most common, used in architecture, home appliances, utensils |

| BA | Bright Annealed | Bright reflection, mirror-smooth | Home appliances, elevators, decorative parts (no polishing required) |

| 8K | Mirror Finish | Polished surface from 2B or BA | Extremely high reflectivity, mirror-like |

| HL | Brushed/Hairline | Continuous brushing with abrasive material | Silk-like gloss and texture |

NO.1 Finish Stainless Steel Factory

Wanzhi Group offers stainless steel coils, plates, tubes, strips, sheets, decorative panels, and color-coated sheets in a variety of grades (austenitic, ferritic, etc.) and finishes (2D, 2B, 4K, 8K, NO.4, brushed, etc.). We can also offer further processing and custom production based on customer needs.

Finishing and Further Processing

- Slitting: Cutting wide coils into narrow strips of varying widths.

- Crosscutting: Cutting coils into flat sheets of specified lengths.

- Surface Finishing: Polishing (to achieve an 8K mirror finish), brushing (HL finish), frosting, and color coating (PVD).

- Forming: Making welded pipes, embossing, and more.

Stainless Steel NO.1 Finishing Process

- Hot Rolling: The steel billet is rolled at high temperature to the desired thickness.

- Annealing: Heating the steel sheet to a specific temperature and then cooling it to restore its corrosion resistance. Pickling: Use solutions such as nitric acid and hydrofluoric acid for immersion or spraying to remove the black oxide scale formed on the surface during high-temperature rolling and annealing.

- Rinsing and drying: Remove any residual acid and set aside.

Uses of NO.1 Finish Stainless Steel

NO.1 Finish Stainless Steel conforms to ASTM (American Society for Testing and Materials) standards and is a basic industrial surface. Its reflective and rough surface allows it to be processed into more decorative stainless steel or used directly in applications where appearance is less critical.

- It is used to manufacture storage tanks, pipes, heat exchangers, industrial equipment frames, brackets, protective covers, and more.

- NO.1 Finish can be stretched to create components such as industrial sinks, kitchenware blanks, automotive exhaust pipes, and washing machine tubs.

- 8K mirror or brushed stainless steel can be achieved through polishing or frosting.

- NO.1 Finish Stainless Steel offers practical applications. If you are looking for stainless steel suitable for further processing such as stamping, stretching, or polishing, please contact us!