Tinned Steel (Tinplate) is a cold-rolled thin steel sheet coated with a thin layer of metallic tin. It combines the strength of steel with the corrosion resistance, aesthetic appeal, non-toxicity, odorlessness, excellent formability, and weldability of tin. It is widely used in industries such as food and beverage packaging, chemical and pharmaceutical containers, electronic enclosures, chemical drums, and gift packaging.

Tinned Steel Structure

Base Material: Cold-rolled low-carbon steel coil providing primary structural strength.

Tin Coating: Electroplated or hot-dip tinned to deliver rust prevention, corrosion resistance, and weldability.

Surface Treatment: Supports decorative or functional processes including painting, printing, and lamination.

Structural Design: Geometric configurations and joining methods for can body, bottom, and lid.

Sealing System: Sealing processes like crimping, welding, or adhesive bonding ensure secure containment of contents.

Material

- MR Type (Non-metallic Inclusion Controlled Steel): Meets deep drawing requirements, the most common type offering high purity and excellent formability.

- L Type (Ultra-Low Carbon-Nitrogen Steel): Meets ultra-deep drawing requirements with extremely low carbon and nitrogen content, providing outstanding aging resistance and formability.

- D Type (Aluminum-Killed Steel): High strength achieved through aluminum deoxidation, delivering tough mechanical properties.

- TH Type (Phosphorus-Hardened Steel): High-strength steel offering both high strength and lightweight characteristics.

Surface

- Bright Surface (Code: B): Mirror-like finish with a lustrous appearance.

- Stone-textured Surface (Code: R): Silver-gray matte finish with subtle textured patterns.

- Silver Surface (Code: S): Characteristic appearance of hot-dip tin plating, featuring a thick tin layer with a distinctive “silver-white” texture.

- Matte Surface (Code: M): Natural, non-glossy finish achieved by omitting soft annealing after tin plating.

Tin Coating Quantity Codes

| Type | Tinning Quantity Code (US System) | Approximate Metric Tinning Quantity (g/m²) |

| Equal Thickness | #25 | E2.8/2.8 (11.2) |

| Equal Thickness | #50 | E5.6/5.6 (22.4) |

| Equal Thickness | #75 | E8.4/8.4 (33.6) |

| Differential Thickness | #50/#25 | D5.6/2.8 (22.4/11.2) |

| Differential Thickness | #75/#25 | D8.4/2.8 (33.6/11.2) |

Tempering Degree Code

| Temper Designation | Characteristics |

| T-1, T-2 | Soft, with excellent formability |

| T-3 | Standard hardness, with a balance of formability and strength |

| T-4, T-5 | Hard, with high strength |

| T-6 | Extra-hard |

Tinned Steel Advantages and Applications

Tinned steel has become a core material in food packaging, electronics, automotive, and construction sectors due to its superior rust resistance, low cost, non-toxicity, corrosion resistance, printability, and environmental friendliness.

Advantages

- Rust Prevention: The tin coating isolates air and moisture, preventing steel plate corrosion.

- Cost-Effectiveness: Compared to stainless steel, tinplate steel offers mature, high-efficiency processes at lower costs.

- Safety and Hygiene: Tin is a non-toxic, odorless metal widely recognized as a safe food contact material.

- Mechanical Strength: Tinplate offers superior strength and rigidity, enabling thinner, lighter containers with enhanced compression and impact resistance.

- Versatility: Diverse forming processes like deep drawing, shallow drawing, and bulging produce circular, square, or irregular-shaped containers.

- Decorative Properties: Tinplate offers diverse surface finishes including glossy, matte (stone-textured), and supports offset and gravure printing.

- Environmental Sustainability: Tinplate is a quintessential “green packaging” material with permanent recyclability.

Applications

- Food Packaging: Bottle caps, food cans, dry food containers, beverage cans, candy boxes, tea tins, cookie tins, etc.

- Chemicals & Pharmaceuticals: Chemical containers, aerosol cans, packaging for paints, oils, pharmaceuticals, etc.

- Electromechanical & Hardware: Labels, toys, small hardware items, gifts, valves, water pipes, radiators, etc.

- Electronics: Raw materials or packaging for electronic component housings, battery casings, etc.

- Other: DIY materials, cultural and creative products, smart packaging.

Tinned Steel Customization

Wanzhi Group Factory is located in Boxing County, Binzhou City, Shandong Province, China. We operate a coating plant, laboratory, and sample room to support customization of substrates, coatings, mechanical properties, dimensions, and surface treatments. Lead time for tinned steel is 5-45 business days with a minimum order quantity of one coil. Select specifications are available from stock.

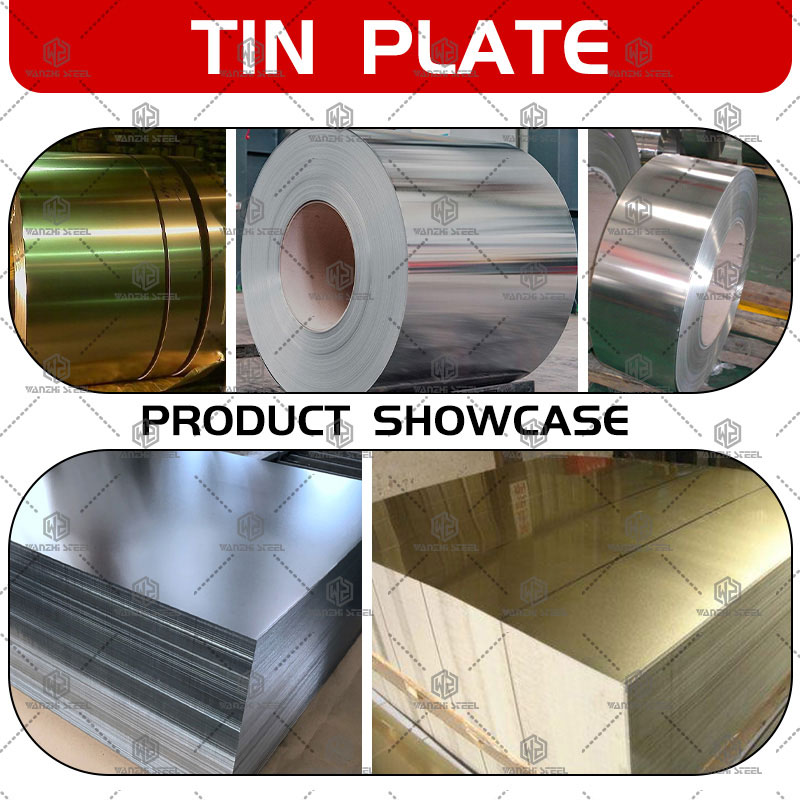

Factory of Tinned Steel

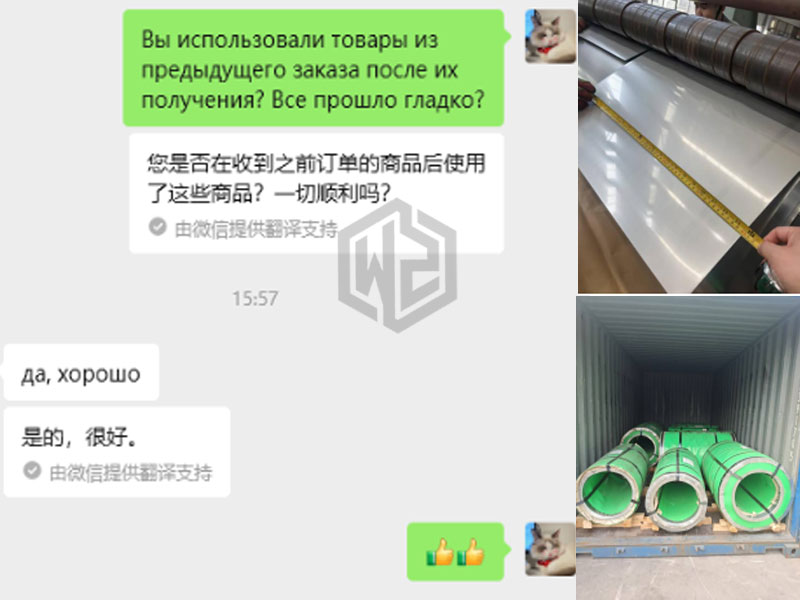

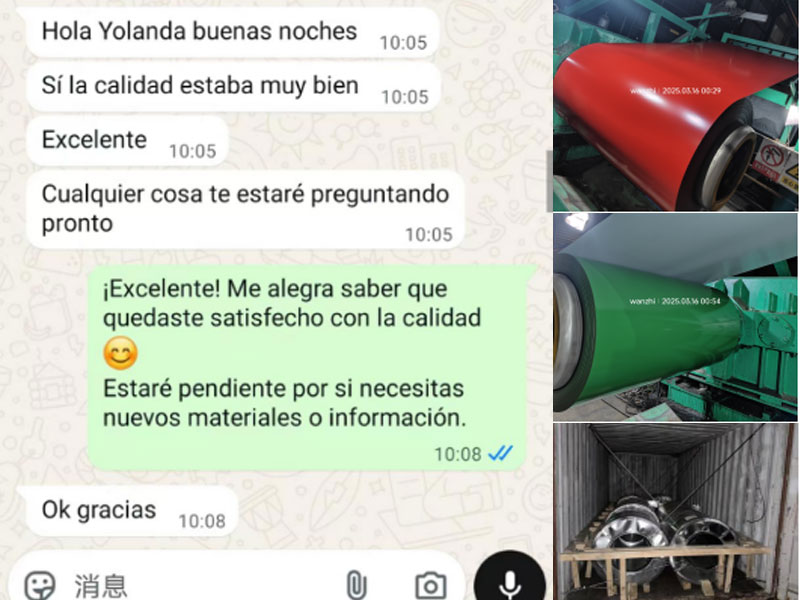

Customer Feedback

Process

- Requirements: Define application scenarios, transportation methods, etc.

- Materials: Determine substrate thickness, tin plating quantity, coating type.

- Samples & Testing: Provide samples for quality inspection.

- Process Confirmation: Establish critical process parameters for printing, soldering, coil sealing, etc.

- Quality Control: Develop inspection standards to ensure consistency and reliability of bulk production.

Comparison of Tinned Steel and Chrome-Plated Steel

| Property | Tin-Plated Steel | Chrome-Plated Steel |

| Coating Composition | Metallic tin | Metallic chromium + chromium hydrated oxide |

| Appearance | Silvery-white luster | Matte silver-gray |

| Corrosion Resistance | Excellent. | Good. |

| Weldability | Excellent. | Poor. |

| Paintability and Adhesion | Good. | Superb. |

| Formability | Excellent | Excellent |

| Cost | High (tin is a precious metal). | Low. |

If you’re seeking metal solutions for packaging or other applications, feel free to contact us for a free quote!