VCM Sheet stands for Vinyl Clad Metal sheet or Vinyl Laminated Metal sheet. It is a composite panel manufactured by bonding a plastic film to a steel or aluminum metal substrate using an adhesive. The surface can be pre-printed with various wood grain, stone patterns, solid colors, or designs, and embossed with different textures (such as brushed or leather finishes). It is one of the ideal materials for high-end home appliances.

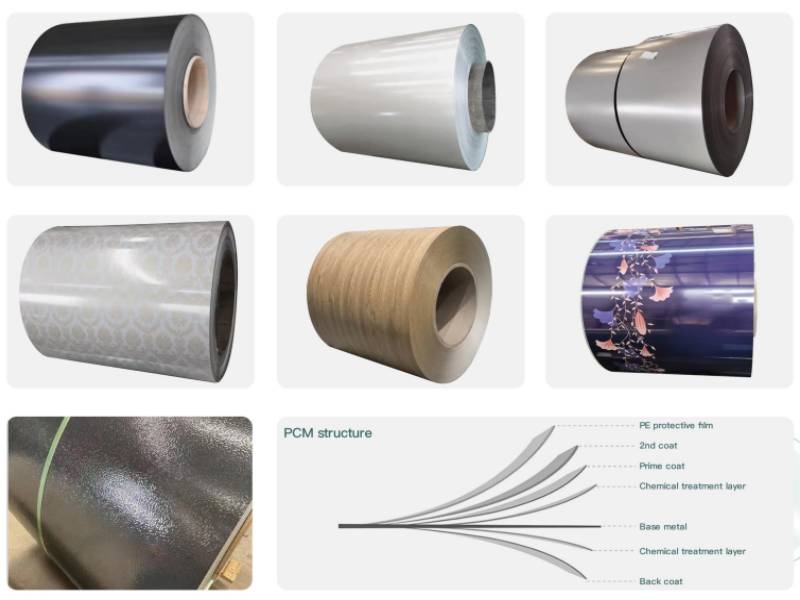

Structure of VCM Sheet

VCM sheet is a laminated metal panel, which can be simply understood as a “sandwich” composite material consisting of a metal substrate + adhesive + decorative plastic film.

Composition

Substrate: Typically cold-rolled steel sheet, galvanized steel sheet, aluminum sheet, or other metallic materials.

Adhesive Layer: The substrate and decorative film are firmly bonded together through a high-temperature, high-pressure process.

Coating Layer: Films made of PVC (polyvinyl chloride), PET (polyethylene terephthalate), PETG, etc., with thickness ranging from 0.1 to 0.5 mm.

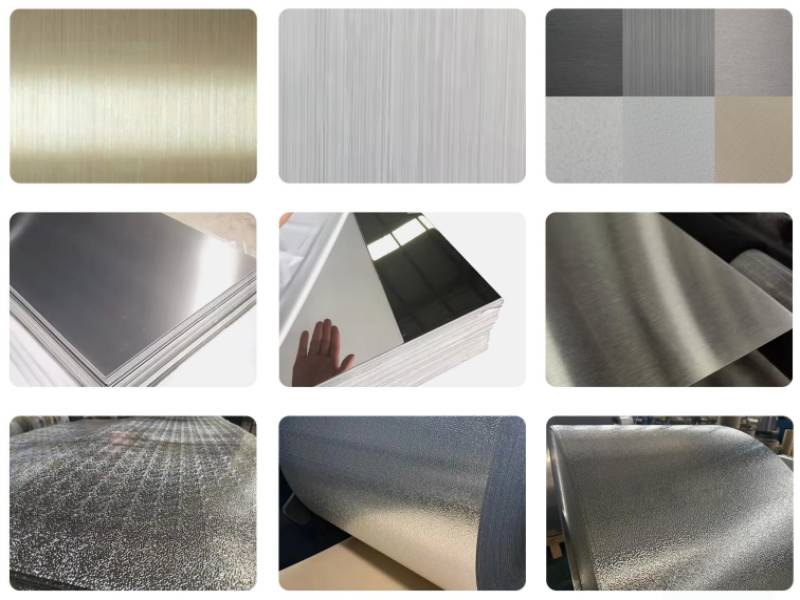

Surface Effects

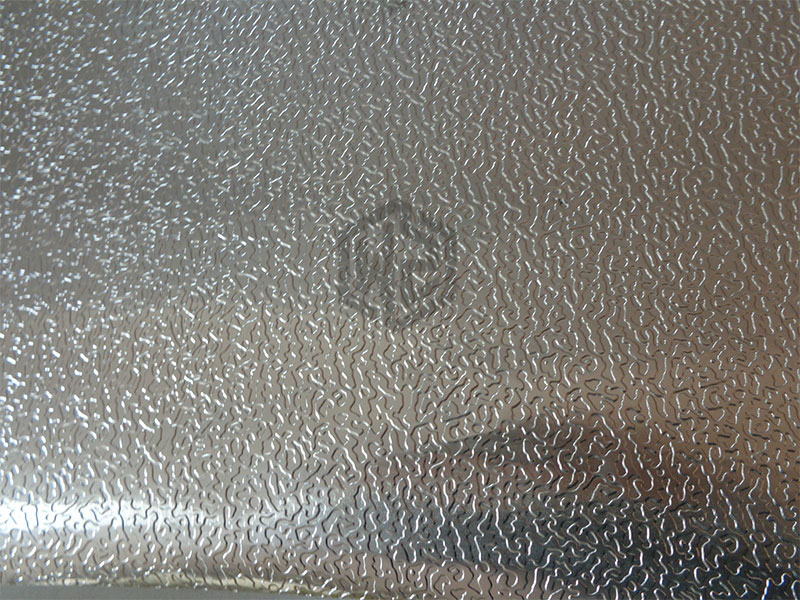

Gloss Level: Matte, High-gloss/Mirror finish

Colors & Patterns: Brushed, Matte, Velvet, Leather grain, Wood grain, Stone texture, Embossed dots, Stainless steel imitation, or Pearl effect.

Classification of VCM Sheets

PVC-Coated Sheets: Metal sheet + PVC film, the most classic and common VCM sheet. Surfaces can feature rich patterns like wood grain, stone texture, or leather grain. Offers diverse colors and patterns, excellent texture, and high cost-effectiveness.

PET-Laminated Panels: Metal sheet + PET film. Typically superior to PVC in environmental friendliness and performance, representing the current mainstream trend. Features include eco-friendliness, scratch resistance, high hardness, and a brilliant appearance.

PETG-Laminated Panels: Metal sheet + PETG film. Characterized by excellent toughness, ease of processing and forming, and impact resistance.

PET Polymer Composite Panels: Primarily composed of metal sheet + PET film, offering enhanced performance and environmental sustainability.

Brushed Film-Coated Panel: VCM panel integrating brushing and film-coating technologies. Surface lines are formed via brushing on the plastic film before high-temperature lamination onto the metal sheet.

High-Gloss Film-Coated Panel: Mirror-like, luxurious VCM panel produced through specialized composite processes. Enhanced surface thickness enables high-temperature bonding at joints.

Advantages and Applications of VCM Laminated Sheets

VCM sheets combine the strength of metal with the decorative appeal of plastic film. In industrial production, they can replace traditional materials like wood, aluminum, and stainless steel, enhancing product aesthetics, extending service life, and reducing project costs.

Advantages

- Decorative Appeal: Rich patterns, diverse textures, and vivid colors

- Physical & Chemical Properties: Corrosion-resistant, stain-resistant, scratch-resistant, and flexible

- Processing Flexibility: Supports cutting, punching, bending, and other advanced fabrication techniques

- Cost-Effectiveness: Lower cost than solid wood veneering or high-end spray coating processes

Applications

- Refrigerator doors

- Washing machines

- Microwave ovens

- Electric ovens

- Water heaters

- Small appliances

- Door panels

- Furniture

- Elevator cabins

- Wall cladding panels

Wanzhi Group VCM Sheet Factory

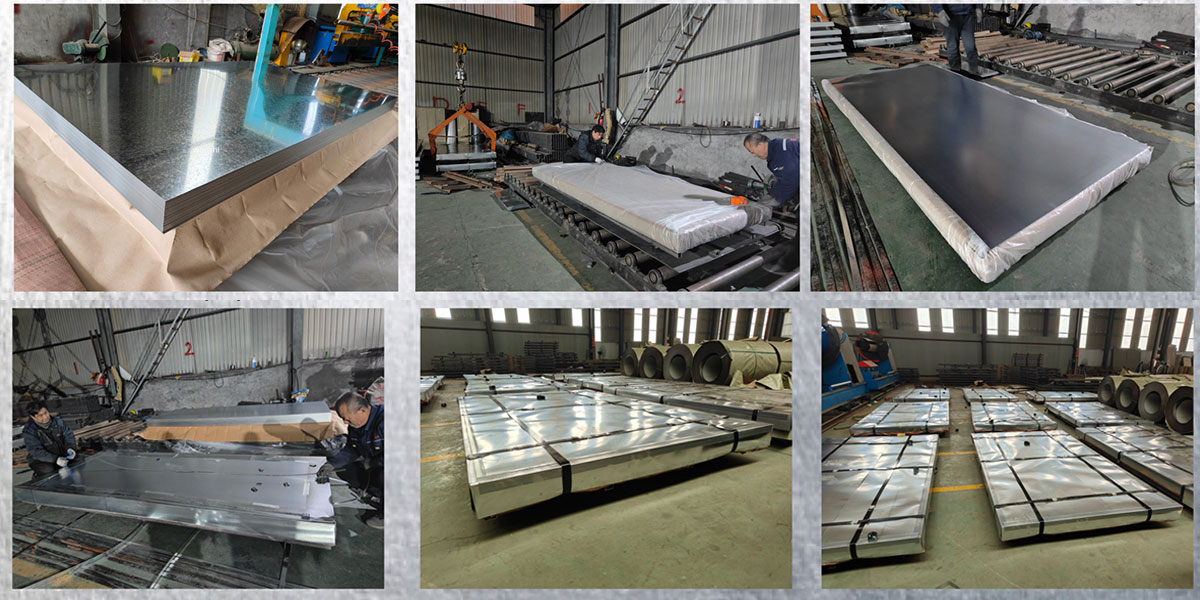

Wanzhi Group maintains a comprehensive supply chain management system. We operate metal substrate production lines and VCM production lines, while maintaining long-term, stable partnerships with renowned domestic plastic film manufacturers to ensure strict quality control over every batch of VCM sheets.

Quality Management

From incoming inspection of raw materials (metal coils, films, adhesives) to in-process monitoring (film thickness, color difference, etc.), and culminating in performance testing of finished products, Wanzhi Steel Factory maintains a comprehensive quality system to ensure product consistency.

VCM Sheet Packaging

Case

VCM Laminated Panels vs. Spray-Coated Panels

| Characteristic | VCM Sheet | Sprayed Coated Sheet |

| Process | The pattern is printed on PVC/PET film and bonded to the metal substrate via adhesive and heat pressing. | Paint is sprayed onto the metal substrate and baked to form a cured coating. |

| Appearance | Extremely rich, can simulate wood grain, stone pattern, fabric texture, etc., and achieve finishes like brushed, mirror, or orange peel textures. High-end appearance. | Simple appearance, mainly solid colors, metallic shades, basic pearl effects, and orange peel textures. |

| Performance | Excellent corrosion and scratch resistance, and environmental friendliness. | Good corrosion and scratch resistance, excellent weather resistance. |

| Cost | Relatively high | Relatively low |

| Processing | Average | Good |

| Main Applications | High-end household appliances, high-end cabinets, interior decorative doors, elevator cabins. | Mid-to-low-end household appliances, electrical enclosures, office furniture, building roofs/walls. |

VCM Sheet and PCM Sheet

| Characteristic | VCM sheet | PCM sheet |

| Process | Laminating | Roller coating |

| Appearance | High decorative appearance | Functional decoration |

| Performance | – Weather resistance: Good | – Weather resistance: (e.g., PVDF) |

| – Chemical resistance: Excellent | – Chemical resistance: Good | |

| – Scratch resistance: Excellent | – Scratch resistance: Good | |

| – Environmental friendliness: PET film is more eco-friendly | – Environmental friendliness: Production is eco-controlled | |

| Cost | Relatively high | High cost-performance ratio |

| Processing | Ordinary laminated boards may have rebound stress at bending and stamping areas, causing film cracks in deep stamping. | The coating has a strong bond with the substrate and can withstand certain bending and stamping without peeling or cracking. |

| Main Applications | Household appliance appearance parts | Household appliance structural and appearance parts, building project materials |

VCM Sheet represents an advanced form of “decorative laminate” or “color-coated steel sheet,” widely used in the production and processing of products emphasizing aesthetic design and texture. It fulfills design requirements for intricate patterns, natural material imitations, or tactile three-dimensional effects.