Brushed metal laminate sheet combines the brushed texture of metal with laminate technology, offering metallic aesthetics, durability, ease of fabrication, and design flexibility. It meets diverse requirements such as rich color options, complex deep-drawing, or bending processes, and is widely used in interior design, furniture manufacturing, and commercial space decoration.

Brushed Metal Laminate Sheet for Sale

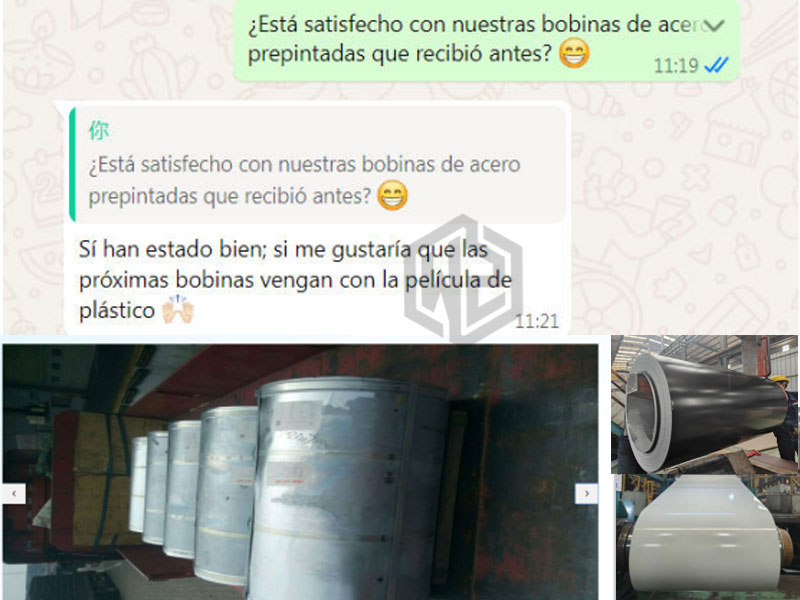

Wanzhi Group manufactures and sells VCM sheets in various materials and surface finishes, including Brushed Metal Laminate Sheets and PET/PVC Laminate Sheets, while offering OEM and ODM services.

Customization

Base Material Selection: Cold-rolled steel or aluminum alloy.

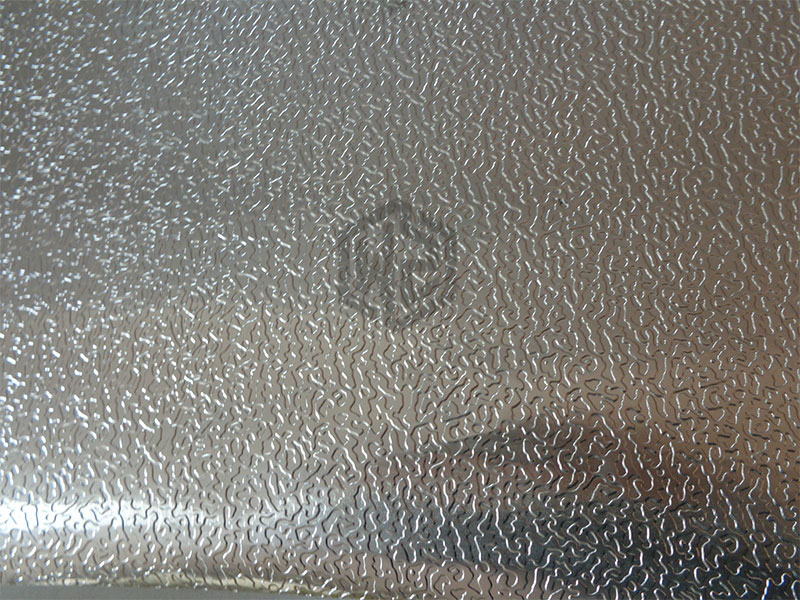

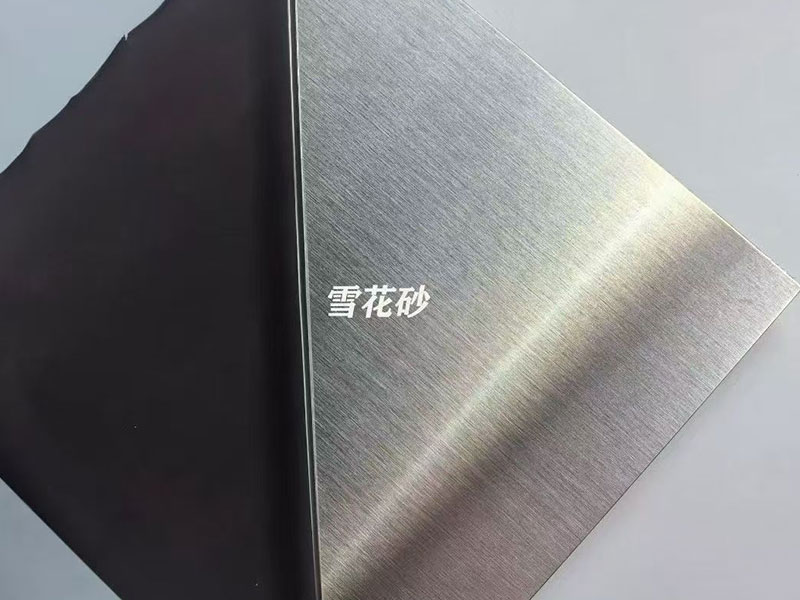

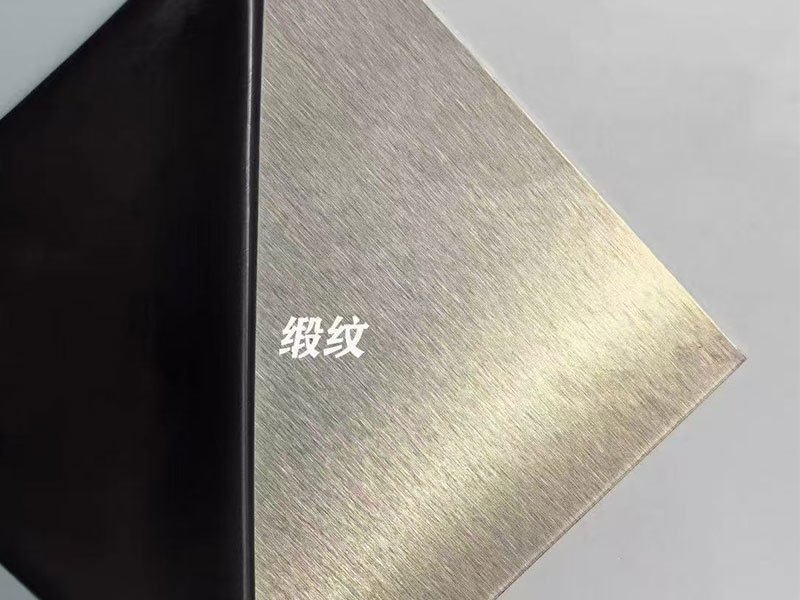

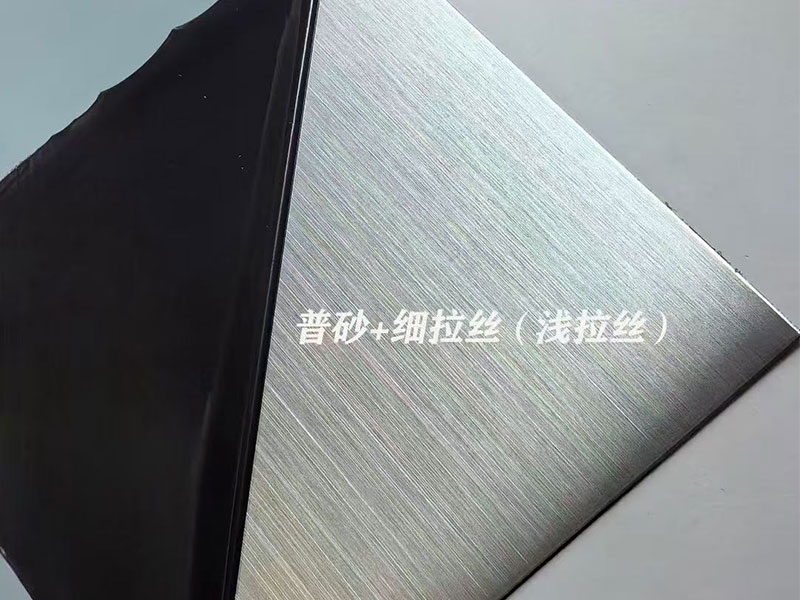

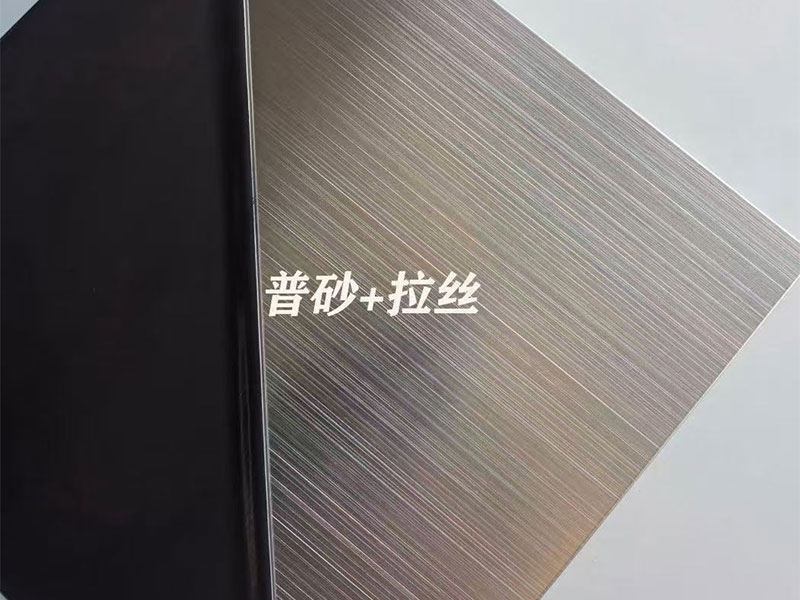

Brushed Textures: Fine straight grain, soft random grain, circular thread patterns, etc.

Colors & Gloss: Available in stainless steel natural, black, champagne gold, rose gold, titanium gold, and more. Customizable finishes include matte, glossy, and other gloss levels.

Surface Feel: Standard smooth texture or customizable authentic metallic feel with subtle friction.

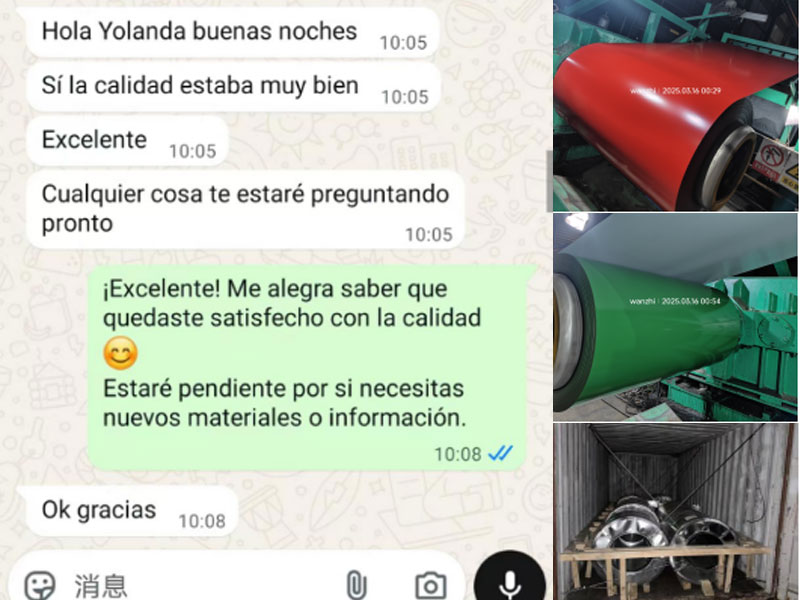

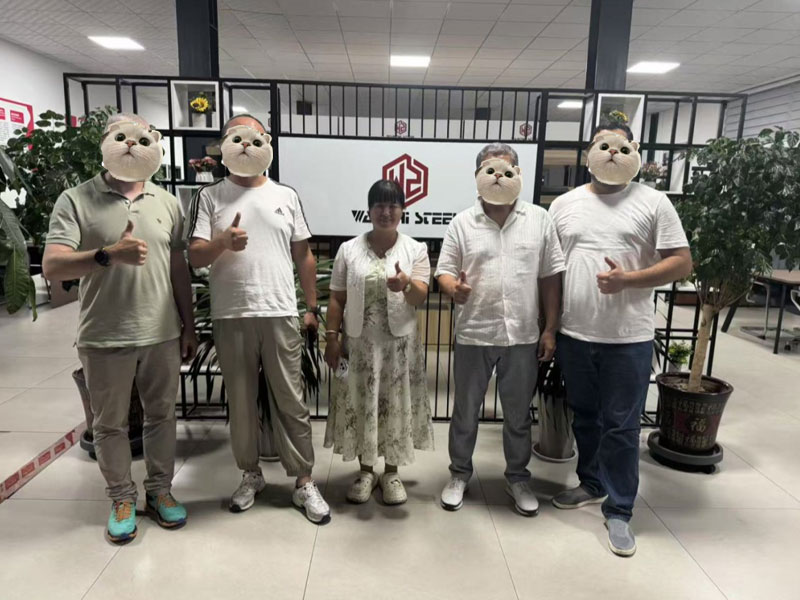

Customer Feedback

Brushed Metal Laminate Sheet Advantages

Metallic Finish: Brushed plastic film imparts a premium metallic texture to VCM material.

Durability: Metal laminate offers exceptional abrasion and corrosion resistance.

Workability: Easily cut, drilled, and bent for on-site installation and customization.

Design Flexibility: Available in diverse metallic colors and textures, including stainless steel silver, aluminum gold, and copper tones.

Lightweight: Compared to solid metal sheets, brushed metal laminate is lighter, simplifying transportation and installation.

Applications of Brushed Metal Laminate Sheet

Brushed Metal Laminate Sheet achieves rich metallic decorative effects at minimal cost, making it a preferred material for high-end appliance panels, elevator interiors, office furniture, and commercial decor.

- Appliances: High-end refrigerators, ovens, dishwashers, range hood panels, etc.

- Architecture: Elevator cabs, interior/exterior wall panels, cabinet doors, commercial space trim, etc.

- Furniture: Office partitions, filing cabinets, kitchen cabinets, tabletops, etc.

- Electronics: Equipment, smart home devices, server cabinet enclosures, etc.

- Transportation: Decorative panels for ship interiors, RV interiors, etc.

- Signage & Display: Backdrops, logos, display stands, etc.

Brushed Metal Laminate Panels and Brushed Metal Sheets

Brushed surfaces offer unique wear resistance, slip resistance, and decorative appeal. Currently, Wanzhi Group’s brushed metal materials include brushed metal laminate panels, brushed aluminum sheets, and brushed stainless steel. Among these, brushed metal laminate panels have become a popular choice due to their more economical cost, easier processing methods, and greater design possibilities.

| Characteristic | Brushed Metal Laminated | Brushed Aluminum | Brushed Stainless Steel |

| Structure | Composite material (metal substrate + imitation metal film) | Pure metal (aluminum) | Pure metal (stainless steel) |

| Cost | Most cost-effective | Moderate | Highest |

| Weight | Can be light or heavy, depending on the substrate | Lightest | Heaviest |

| Strength/Hardness | Determined by the substrate | Lower | Highest |

| Corrosion Resistance | Excellent | Excellent | Good |

| Processing Performance | Excellent | Excellent | Difficult |

| Appearance Diversity | Can be customized in any color (e.g., black steel, champagne gold), with strong texture consistency. | Mostly in the original color of aluminum, anodized colors, or painted colors, with fewer choices. | Original color of stainless steel or electroplated colors (e.g., titanium gold, black titanium). |

| Touch and Temperature | Laminated surface feel, warm and not cold. | Metallic touch, with a strong cold sensation. | Metallic touch, with the strongest cold sensation. |

Brushed Metal Laminated Panel Supplier

Wanzhi Group possesses R&D, production, and customization capabilities for brushed metal laminated panels. We offer one-stop services from substrate and lamination to processing, supporting third-party inspections by SGS, BV, and others.

Factory

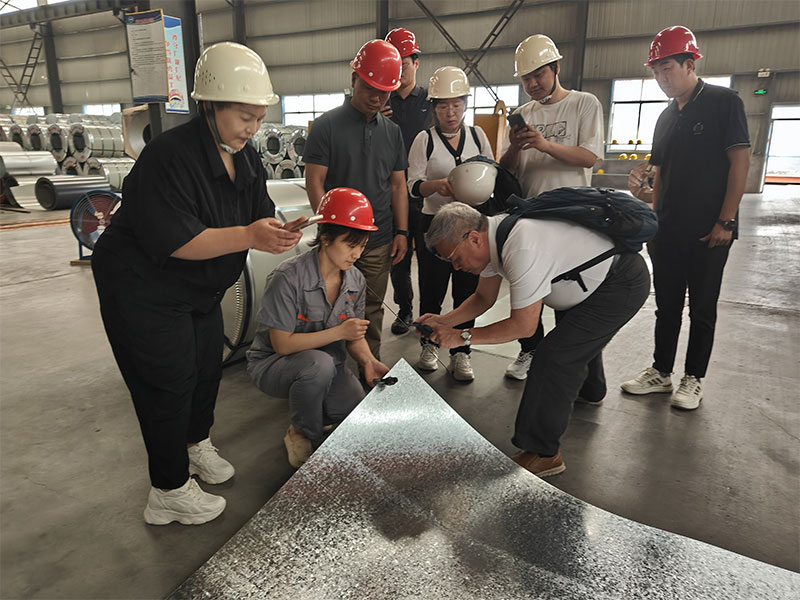

Our facility is located in Boxing County, Binzhou City, Shandong Province, China. We feature precision cleaning and pretreatment, high-speed precision coating, and online quality monitoring systems. We also provide secondary processing and forming services for coil and sheet materials, including precision slitting/coil cutting, precision cross-cutting/flattening, stamping, bending, cutting, welding, and assembly. If you plan to visit our VCM sheet or other coated steel facilities, please contact us—we’d be delighted to arrange your tour.

Services

One-Stop Customization: We provide full technical support from substrate selection and texture design to processing and forming.

Quality Certification: Our factory holds ISO9001 and other international management system certifications, ensuring stable and reliable product quality.

Technical Support: Our experienced team provides optimal material selection and process recommendations tailored to your specific applications.

If you’re seeking a metal surface treatment solution that elevates your product’s sophistication, aesthetics, and functionality, Brushed Metal Laminate Sheet is your ideal choice. Contact us anytime to request complimentary sample books and detailed technical specifications!