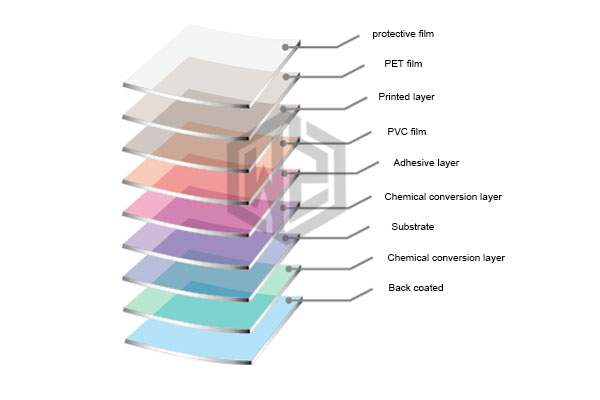

PET laminated sheet is an advanced composite material featuring a high-quality metal substrate core laminated with PET (polyethylene terephthalate) film. With its outstanding eco-friendly properties, scratch resistance, durability, and premium tactile experience, it has become the material of choice for high-end home appliances, modern home furnishings, and commercial space decoration. It offers the perfect solution for markets pursuing both quality and sustainability.

Custom PET Laminated Sheets

PET laminated sheets consist of cold-rolled steel or aluminum alloy substrates, eco-friendly high-performance adhesives, and PET film layers. The metal substrate provides robust structural support, while the PET film imparts unique surface properties. Wanzhi Group offers comprehensive OEM/ODM services for PET laminated sheets, catering to your brand’s personalized needs from substrate selection to surface finishes.

Base Material Customization

- Cold-Rolled Steel Coil (CRC): Economical and practical, easy to stamp and form.

- Aluminum Alloy: Lightweight, high strength, corrosion-resistant, suitable for weight-sensitive applications.

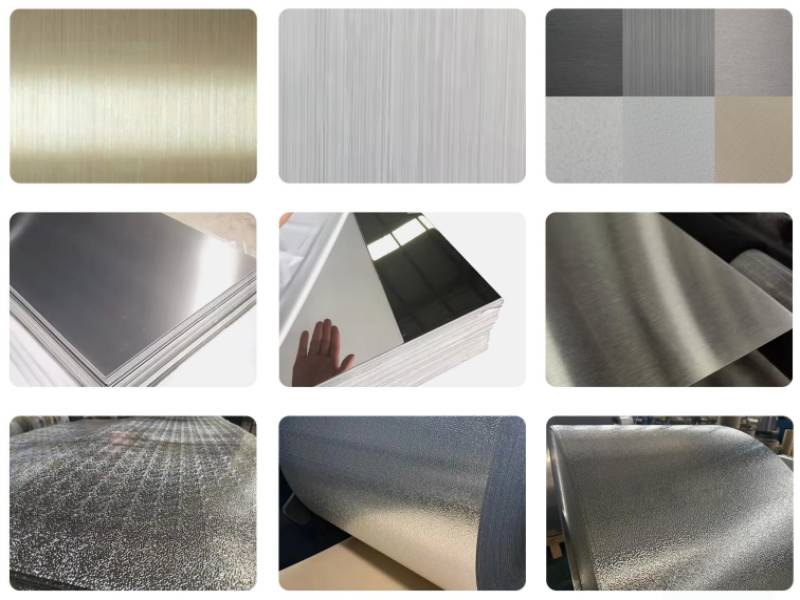

PET Film Customization

Gloss Level Options

Matte: Premium texture, fingerprint-resistant, glare-free.

High Gloss: Vibrant colors, outstanding mirror-like effect, easy to clean.

Skin-Feel: PET’s signature tactile experience—smooth, delicate, and highly fingerprint-resistant.

Patterns & Colors

- Customizable to any RAL color code with pure, saturated hues.

- Offers diverse styles including wood grain, stone texture, fabric weave, geometric abstracts, natural landscapes, and metallic finishes.

Surface Texture & Tactile Feel

- Skin-like Touch: Delivers an unparalleled skin-friendly experience.

- Velvety Touch: Warm, soft, and exceptionally luxurious.

- Custom Options: Special textures and tactile sensations can be developed upon request.

Advantages and Applications

PET laminated sheet is a high-performance eco-friendly decorative material that surpasses traditional PVC materials in overall performance, making it the preferred choice for mid-to-high-end decorative markets.

Characteristics of PET Film

- Ultimate Eco-Friendliness and Safety: Manufactured from food-grade PET raw materials, it is odorless, free of heavy metal residues, and certified under the most stringent environmental standards (e.g., REACH, ROHS).

- Superior Chemical Resistance: Highly resistant to everyday chemicals (e.g., alcohol, cleaners, cosmetics), resisting corrosion and discoloration.

- Exceptional Durability: Significantly outperforms PVC film in yellowing resistance and scratch resistance, maintaining a fresh appearance over time.

- Robust Weather Resistance: Excellent stability under UV exposure, resisting chalking and fading.

- Recyclability: A more sustainable green material.

Advantages of PET Laminated Sheet

- Premium Tactile Experience: The skin-like surface texture is its standout feature, significantly enhancing product value.

- Long-lasting Fresh Appearance: Exceptional scratch and stain resistance ensures products remain pristine even after prolonged use.

- Superior Processability: Excellent flexibility allows bending, stamping, cutting, and other secondary processing to meet complex design demands.

- Premium Choice: Though slightly more expensive than standard PVC, it delivers superior aesthetics, tactile quality, and durability that far exceed its price point.

Application of PET Laminated Sheet

- High-end appliance panels

- Premium cabinet and wardrobe doors

- Office and commercial furniture

- Eco-conscious spaces like healthcare and education facilities

- Electronic device enclosures

PET Laminated Sheet vs. PVC Laminated Sheet

PET laminated and PVC laminated sheets are two popular types of VCM sheets, each offering distinct advantages in environmental friendliness, safety, tactile experience, appearance, durability, and cost. You may select based on your requirements or contact Wanzhi Group for a complimentary solution.

| Characteristic Dimension | PET Laminated Sheet | PVC Laminated Sheet |

| Environmental Friendliness | ★★★★★ | ★★★☆☆ |

| Touch and Appearance | ★★★★★ | ★★★★☆ |

| Durability | ★★★★★ | ★★★★☆ |

| Chemical Resistance | ★★★★★ | ★★★★☆ |

| Physical Properties | ★★★★☆ | ★★★★☆ |

| Temperature Tolerance | ★★★★★ | ★★★☆☆ |

| Cost-Effectiveness | ★★★☆☆ | ★★★★★ |

| Application Scenarios | High-end and environmentally sensitive markets | Widespread mainstream and cost-effective markets |

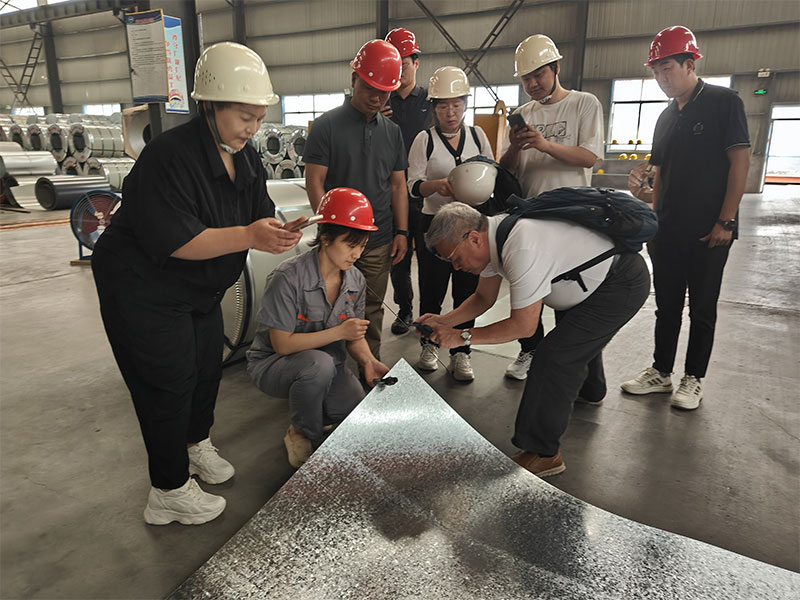

Why Choose Us?

Our PET laminated sheet production base is located in Boxing County, Binzhou City, Shandong Province. Equipped with a comprehensive quality management system and advanced production facilities, our factory holds certifications including ISO9001 and ISO14001. Our products are exported to over 100 countries and regions worldwide.

Services

- Delivery: We provide complimentary samples with order lead times ranging from 5 to 45 business days.

- Supply Chain: Our seven production lines achieve an annual output capacity of 600,000 tons.

- One-Stop Customization: From substrate selection and PET film customization to precision finishing.

- Quality Assurance: Strict adherence to quality control standards, with support for third-party authoritative testing.

- Solutions: We are not only manufacturers but also your material consultants, assisting you in selecting the most suitable solutions for your products.

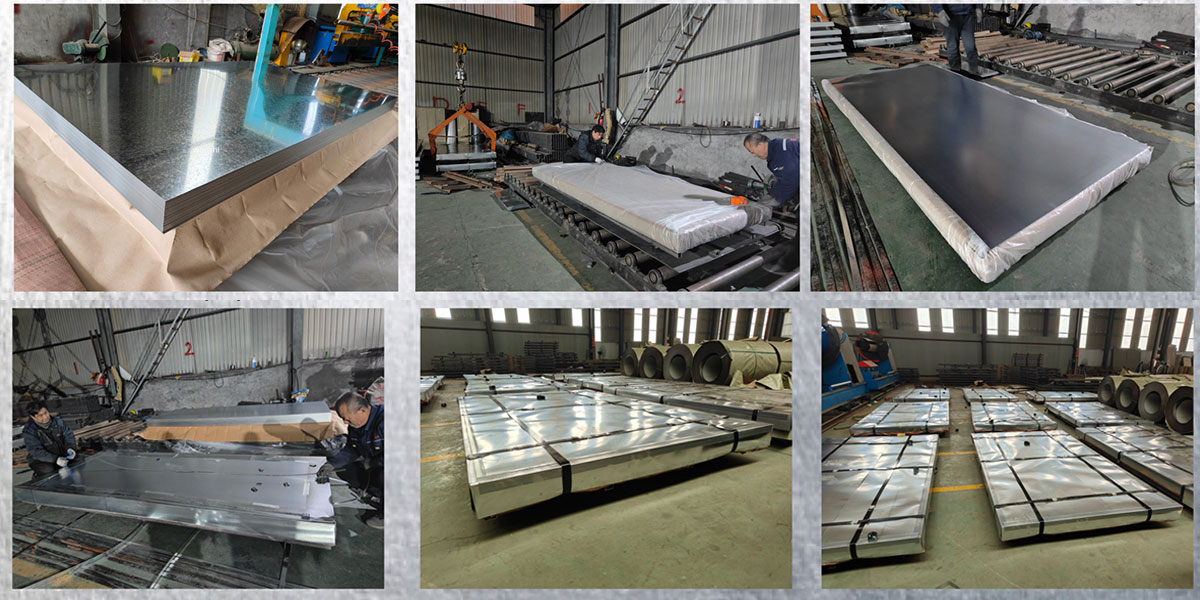

Packaging

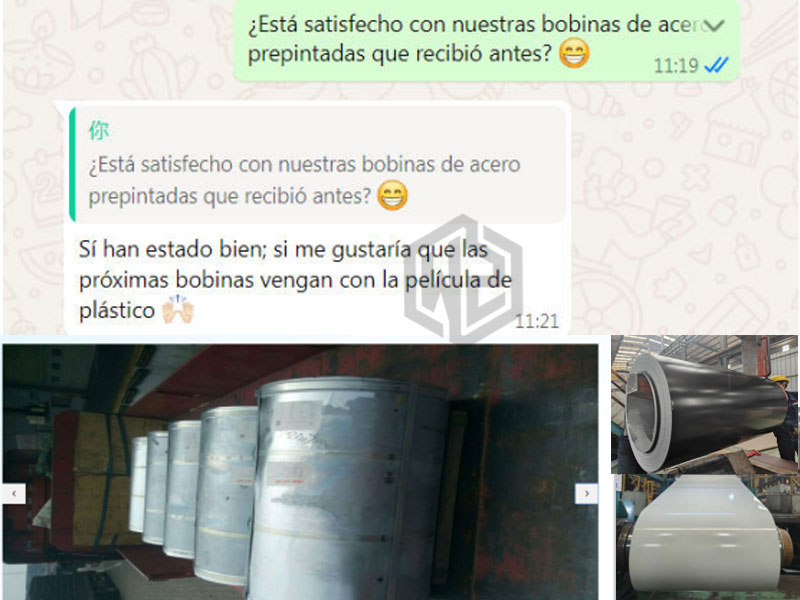

Feedback

If you’re seeking a surface treatment solution for your home appliances or other engineering projects that combines premium aesthetics, top-tier tactile feel, exceptional durability, and eco-friendly safety, PET laminated sheets are undoubtedly your ideal choice. Contact us for free samples and a customized quote!