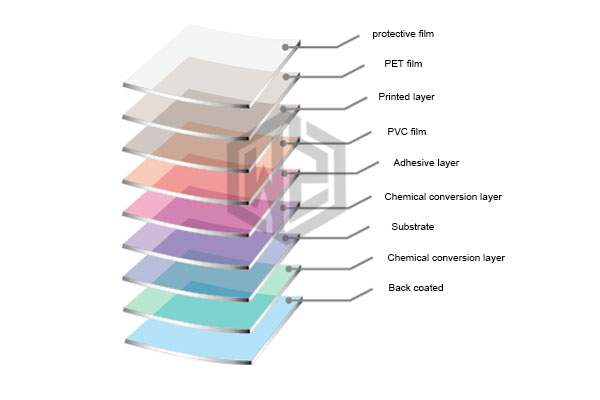

PVC Laminated Sheet is a type of VCM sheet. It is a composite material featuring a metal foil substrate laminated with a PVC film surface. This more environmentally friendly and premium metal material is gaining increasing popularity in high-end home appliances and building materials sectors.

PVC Laminated Sheet Structure

PVC Laminated Sheet essentially involves bonding a high-grade, patterned plastic film to a metal substrate. The metal substrate determines the sheet’s mechanical properties, while the plastic film provides decorative and functional benefits.

Base Substrate: Steel or aluminum sheet, providing structural strength and rigidity.

Adhesive Layer: High-performance adhesive ensuring a durable bond between the film and substrate.

PET Film Layer: Primarily composed of PVC resin, delivering decorative aesthetics and protective functionality.

PVC Laminated Sheet Customization

Wanzhi Group offers OEM/ODM services for PVC laminated sheets. With our metal processing production lines and extensive PVC film resources, we provide comprehensive visual and tactile customization tailored to your brand identity and product positioning. This includes adjustments to gloss level, patterns, colors, textures, and surface feel.

Substrate Customization

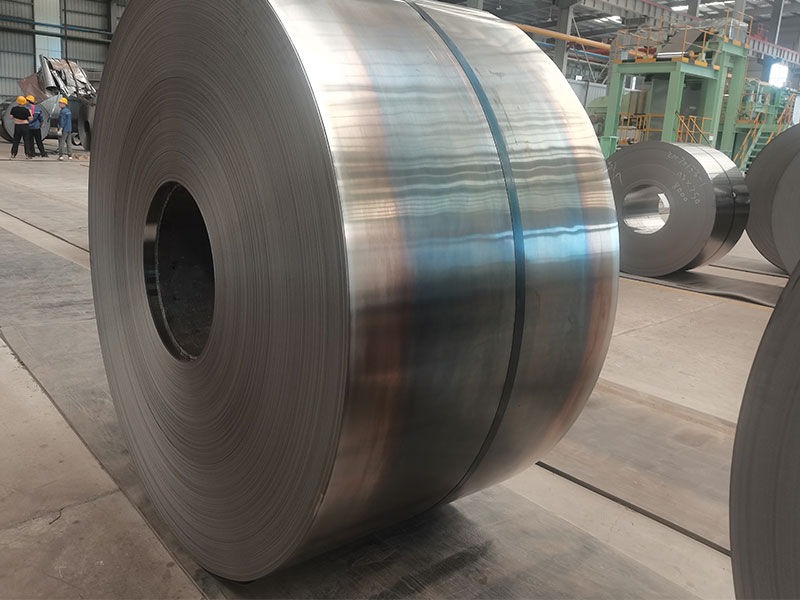

Cold-Rolled Coil: Smooth, flat surface with excellent ductility, easy to stamp and form, cost-effective. Recommended grades: SPCC, SPCD, SPCE / SECC.

Aluminum Alloy: Lightweight, high strength, exceptional corrosion resistance, excellent thermal/electrical conductivity, easy to process. Recommended grades: 5052 / 5754, 3003, 6061.

PVC Film Customization

Gloss Levels

- Matte: Premium texture, fingerprint-resistant, no glare pollution.

- High Gloss: Vibrant, vivid colors with a modern aesthetic, easy to clean.

- Pearlescent: Soft, iridescent effects under varying light angles.

Patterns & Colors

- Solid Color Series: Any RAL color code can be matched.

- Wood Grain Series: Oak, walnut, and natural wood-like patterns.

- Stone Series: Marble, granite, and other natural stone effects.

- Abstract Patterns: Geometric, fabric, and artistic designs.

- Metal Textures: Brushed, mirror-finished, and stainless steel-like finishes.

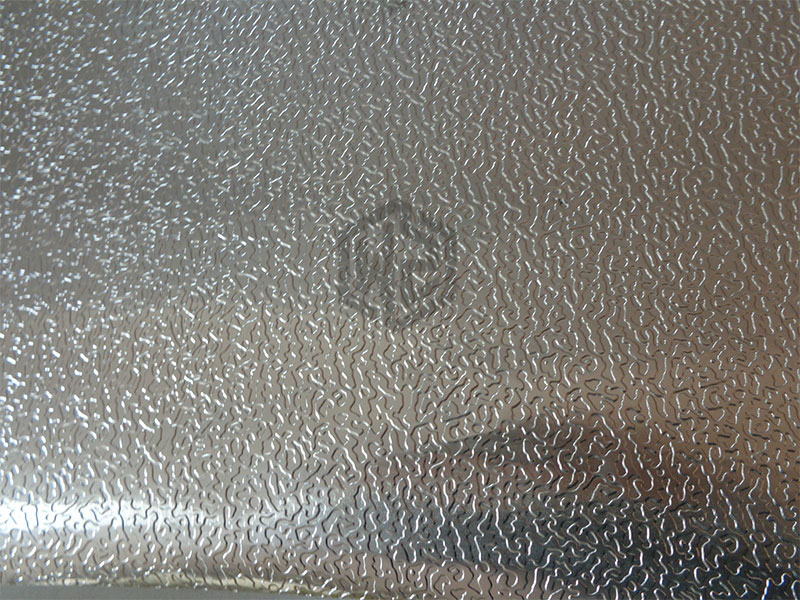

Surface Texture & Tactile Feel

- Textures: Wood grain, leather grain, orange peel, geometric patterns, etc.

- Velvet: Warm, skin-friendly unique feel.

- Satin Touch: Subtle resistance, slip-resistant and premium.

- Silk Touch: Smooth as silk, exceptionally comfortable.

- Other: We can develop custom tactile coatings per your requirements, such as cooling or rubberized sensations.

Advantages and Applications of PVC Laminated Sheets

PVC laminated sheets are suitable for most applications demanding high decorative standards, making them an ideal choice for industries seeking premium aesthetics and exceptional durability.

PVC Film Characteristics

- Corrosion Resistance: Resists acids, alkalis, and salt spray.

- Electrical Insulation: Excellent electrical properties.

- Temperature Tolerance: Operating range from -15°C to 60°C.

- Flame Retardancy: Self-extinguishing properties.

- High Strength: Laminated structure enhances impact resistance.

- Processability: Suitable for secondary processing requirements.

- Eco-Friendly: Non-toxic and odorless, compliant with environmental standards.

PVC Laminated Sheet Characteristics

- Highly Decorative: PVC film can replicate the texture and color of any material, achieving realistic tactile effects.

- Corrosion Resistance: Resists acids, alkalis, salts, oils, and strong chemicals.

- Durability: More scratch-resistant than PCM sheets with superior moisture and water resistance.

- Workability: Bendable, stampable, and cutable for complex designs.

- Cost-Effective: Higher than pre-coated metal sheets but lower than real wood veneer or stone. Offers better value for premium aesthetics.

- Limitations: Film layer may fade or peel over time.

Applications

- Architectural Decoration: Cabinet doors, interior building panels, etc.

- Appliance Panels: High-end refrigerator doors, washing machine panels, etc.

- Furniture Manufacturing: Cabinet and wardrobe doors, office furniture, etc.

- Signage & Display: Outdoor display boards, lightbox panels, electronic device housings, etc.

PVC Laminated Sheet Factory

Our VCM sheet factory is located in Boxing County, Binzhou City, Shandong Province, China. Certified under management systems including ISO9001 and ISO14001, we offer both VCM and PCM production and processing, providing customized solutions tailored to application requirements and usage scenarios.

One-Stop Solutions: From substrate selection and film skin customization to processing and forming (slitting, leveling, bending, etc.), we provide full technical support throughout the entire process.

Flexible Customization: We adapt seamlessly to both small-batch trials and large-scale production runs.

Quality Assurance: Our stringent quality control system supports third-party inspections by SGS, BV, TUV, and other agencies.

Technical Support: We provide material and process selection recommendations tailored to your requirements.

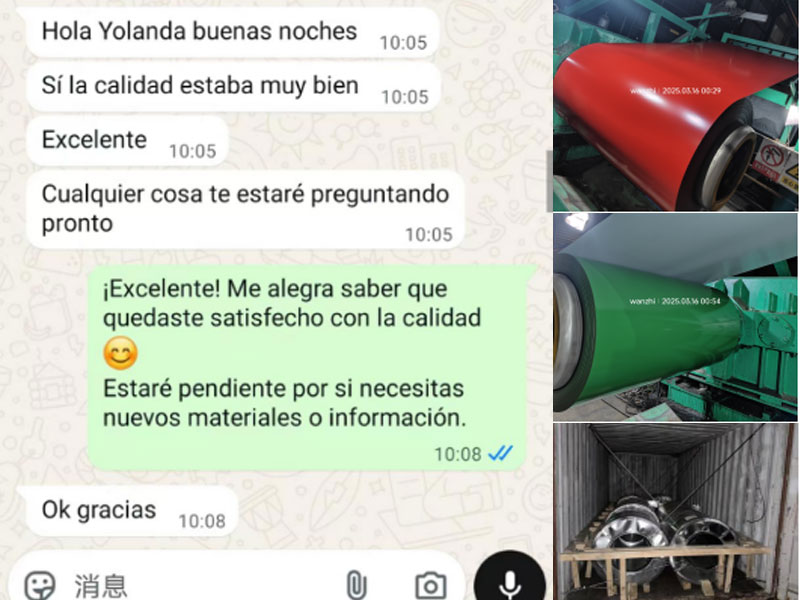

Customer Feedback

Beyond PVC laminated sheets, we offer a diverse range of premium panels including brushed laminated sheets, PET laminated sheets, PET polymer composite panels, PETG laminated sheets, and high-gloss laminated sheets. Share your requirements with us to receive a complimentary quote!