Profiled Metal Roofing has become an indispensable material for building roofs due to its high cost-effectiveness, lightweight nature, quick installation, aesthetic appeal, durability, and strong malleability. It has replaced traditional building materials such as clay/cement tiles and asphalt shingles in numerous applications.

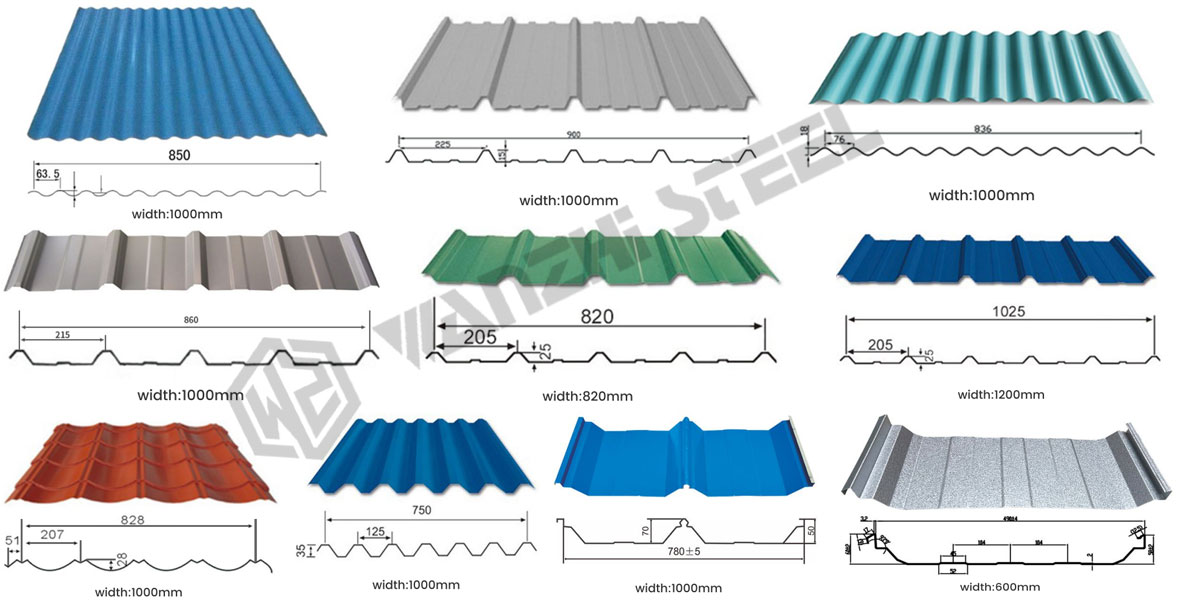

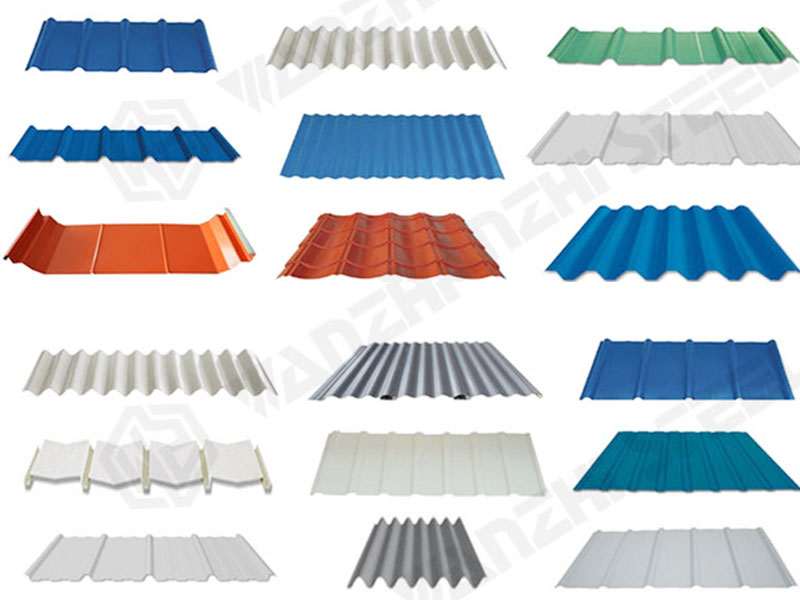

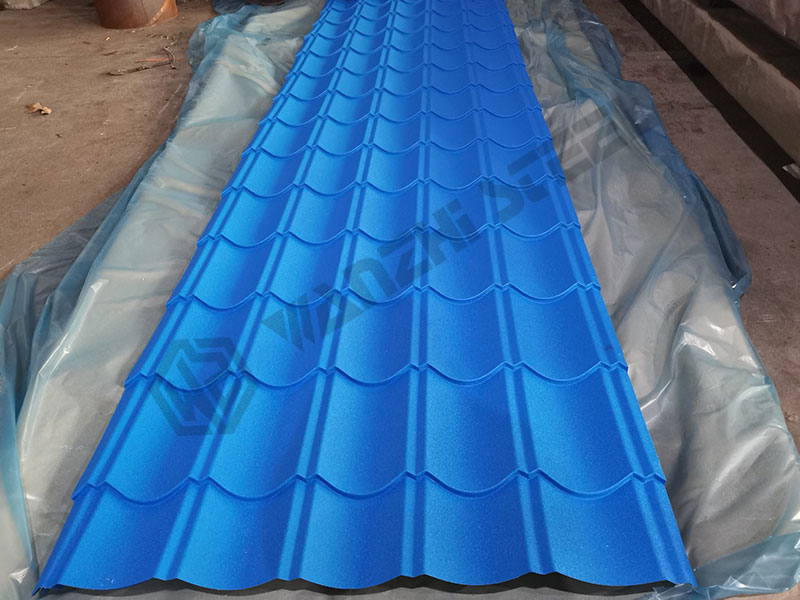

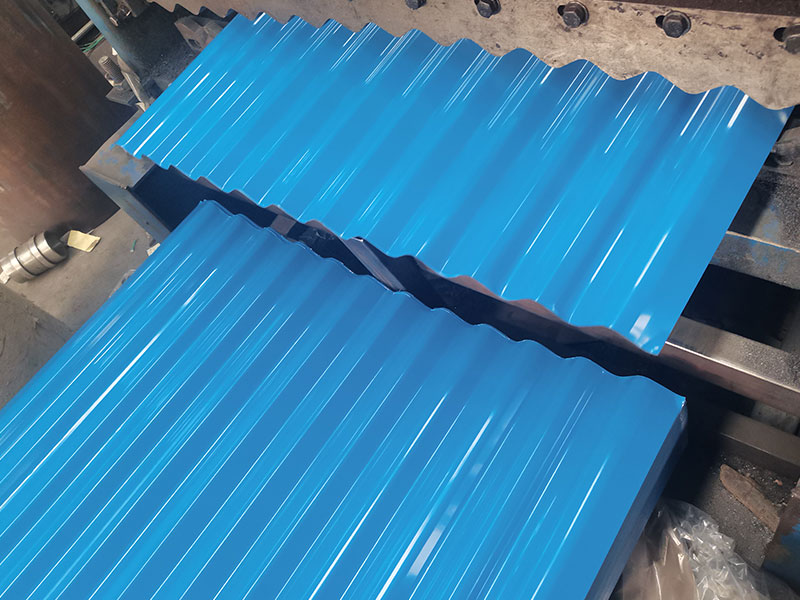

Color-Coated Profiled Metal Roofing

Also known as PPGI/PPGL Profiled Roofing, this is the most common metal roofing material. It is manufactured by applying colored organic coatings/films onto galvanized or aluzinc substrates.

Composition

- Substrate: Aluzinc-coated steel sheet, galvanized steel sheet.

- Coating: Primed and top-coated, with optional protective film overlay.

Coating Types (Key)

- Polyester: Most versatile, cost-effective.

- Silicon-modified polyester: Moderate pricing. An upgraded polyester option.

- High-durability polyester: Performance comparable to silicon-modified polyester with superior formability.

- PVDF: Premium coating offering outstanding performance across all parameters.

Advantages

- Lighter weight than traditional materials, reducing structural load while maintaining high strength.

- HDP, SMP, and PVDF coatings resist UV radiation, acid rain, and corrosion, with lifespans of 15-30 years.

- Customizable colors and surface textures (smooth, textured, woodgrain, stone).

- Easy installation with short construction timelines.

- High cost-effectiveness, lower than stainless steel or aluminum-magnesium-manganese roofing panels.

Disadvantages

- Single-layer PPGI roofing sheets have poor thermal insulation.

- Average sound insulation; significant noise during rainfall.

- Metal materials exhibit noticeable thermal expansion and contraction.

- Prone to corrosion and rust after damage.

Applications

- Industrial plants, logistics warehouses, commercial complexes

- Sports stadiums, exhibition halls

- Agricultural greenhouses

Aluminum-Magnesium-Manganese Alloy Profiled Metal Roofing

Aluminum-Magnesium-Manganese Alloy Profiled Roofing is a premium metal roofing material typically used in standing seam systems.

Advantages

- Resistant to acids and alkalis, with a lifespan exceeding 50 years

- Excellent formability

- Aluminum-Magnesium-Manganese plate is Lighter weight than PPGI or PPGL sheets

- High recyclability

- Superior color retention

Disadvantages

- High cost

- Material price significantly exceeds that of color-coated steel sheets

- Lower rigidity compared to steel sheets

Applications

- Airport terminals, high-speed rail stations

- Large stadiums, convention centers, museums

- Premium commercial complexes

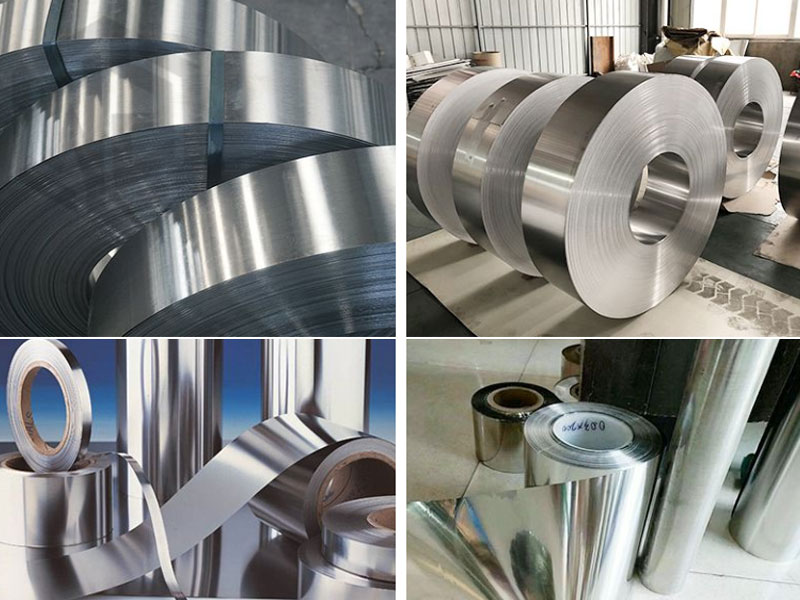

Stainless Steel Profiled Metal Roofing

Stainless steel roofing panels are extremely costly and challenging to fabricate, making them uncommon for general building roofs. They are primarily used in projects requiring extreme corrosion resistance or exceptional durability.

Advantages

- Exceptional durability and strength

- Superior corrosion resistance

- High-temperature tolerance and extreme strength

- Distinctive metallic finish (brushed, polished)

Disadvantages

- Extremely high cost

- Difficult fabrication

- Relatively heavy weight

Applications

- Industrial facilities in chemical, pharmaceutical, and food processing sectors

- Extreme climate architecture

- Landmark structures

If you are selecting suitable profiled metal roofing panels for your project, please contact Wanzhi Group. We manufacture raw materials (PPGI/PPGL/Aluminum-Magnesium-Manganese plate/Stainless Steel sheet) and provide forming services, offering customized roofing panel solutions tailored to diverse industry applications.