Polyvinylidene fluoride (PVDF) coated steel sheets are the top choice for high-end outdoor projects. PVDF coatings boast excellent UV resistance, acid and alkali resistance, and weather resistance, with an outdoor lifespan of 15-20 years, far exceeding PE, SMP, and HDP coatings, making them a popular material for building envelope systems and roofing.

Why is PVDF Coated Steel Recommended for Outdoor Use?

Outdoor buildings need to withstand multiple challenges from sunlight, rain, temperature differences, and industrial environments. PVDF coatings’ unparalleled weather resistance and color retention ensure stable color under any climatic conditions.

Advantages of PVDF (Polyvinylidene Fluoride) Coatings

Extra-long lifespan:Under normal conditions, PVDF coatings have a service life of 20-30 years, with an outdoor lifespan of 15-20 years, during which time no significant chalking, fading, or cracking occurs.

UV resistance:Fluorocarbon chemical bonds effectively absorb UV energy, providing extremely strong UV resistance.

Self-cleaning property:The smooth and dense surface of the PVDF coating does not easily attract dust and contaminants, making it easy to clean. Corrosion Resistance: Resistant to most chemicals such as acid rain, industrial atmospheres, salt spray, and vehicle exhaust.

Scratch Resistance: The coating surface is hard, with superior resistance to abrasion and scratches compared to ordinary paints.

Flexibility: Can be deep-drawn, bent, and roll-formed without cracking or peeling.

Diverse Colors: Available in a variety of standard and custom colors; Wanzhi Coated steel primarily references the RAL color chart.

Superior Texture: High-gloss, matte, and even special metallic textures are available, including orange peel and brushed finishes.

Advantages of PVDF Coated Steel Sheets

Economy: While the initial investment for PVDF coated steel sheets is higher than that for ordinary PE coated steel, they offer a longer service life, better performance, and high cost-effectiveness in the long run.

Durability: High-quality PVDF color-coated sheets typically offer a 15-30 year quality guarantee.

Applicability: Widely applicable to roofs, walls, and curtain walls of landmark buildings such as airports, stadiums, conference centers, high-end office buildings, and hospitals, as well as buildings with extremely high aesthetic requirements. Processability: It can be used as a raw material for various complex profiled steel sheets.

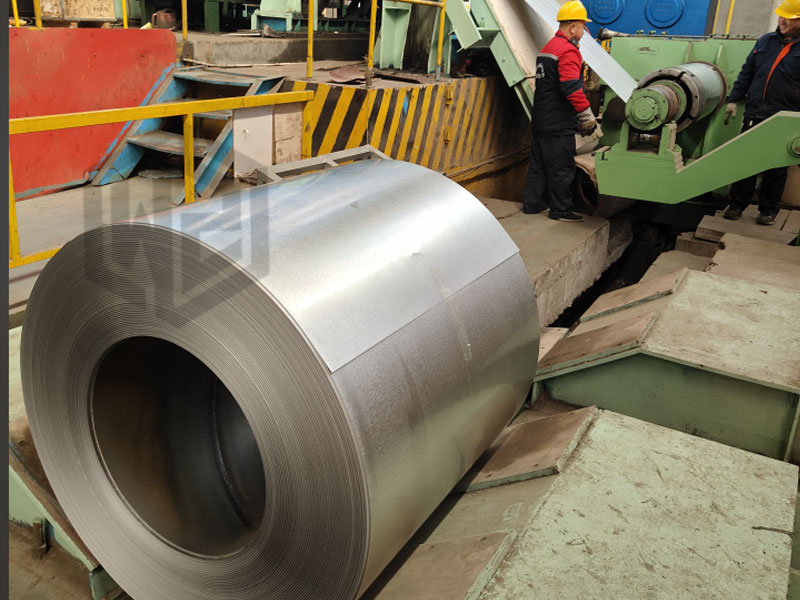

PVDF Coating Combination: GI and GL Substrates

Color-coated steel consists of a metal steel sheet and a colored organic coating. The substrate provides strength, stiffness, toughness, and basic rust protection, while the PVDF coating acts as a physical barrier and provides decorative effects. The combined effect of GI steel/GL steel and PVDF coating creates a durable, high-quality building material!

PVDF GI Coated Steel

PVDF GI coated steel, also known as PVDF PPGI steel, has a galvanized steel (GI) substrate, providing excellent rust resistance and sacrificial protection. This combination of GI substrate and PVDF coating offers high cost-effectiveness and is suitable for most outdoor building environments, such as large industrial plants, logistics warehouses, and commercial buildings.

PVDF GL Coated Steel

PVDF GL coated steel, also known as PVDF PPGL steel, has an aluminized zinc-coated steel (GL, also known as Galvalume) substrate. The GL substrate, due to the addition of aluminum and silicon, has superior corrosion resistance and heat resistance. The combination of PVDF and GL substrates is the optimal choice for demanding coastal buildings or high-standard public facilities.

Whether it’s large-span airport terminals, stadiums, convention centers, high-end commercial buildings, industrial plants, or logistics centers, PVDF coated steel sheets offer reliable solutions. Contact Wanzhi Group for more information and a quote!