Stainless steel has become an indispensable metal material in architecture, home furnishings, and industrial design due to its exceptional corrosion resistance, strength, and decorative appeal. The diverse range of surface treatments available for stainless steel further expands its applications across various fields. Today, let’s explore twelve different stainless steel finishes!

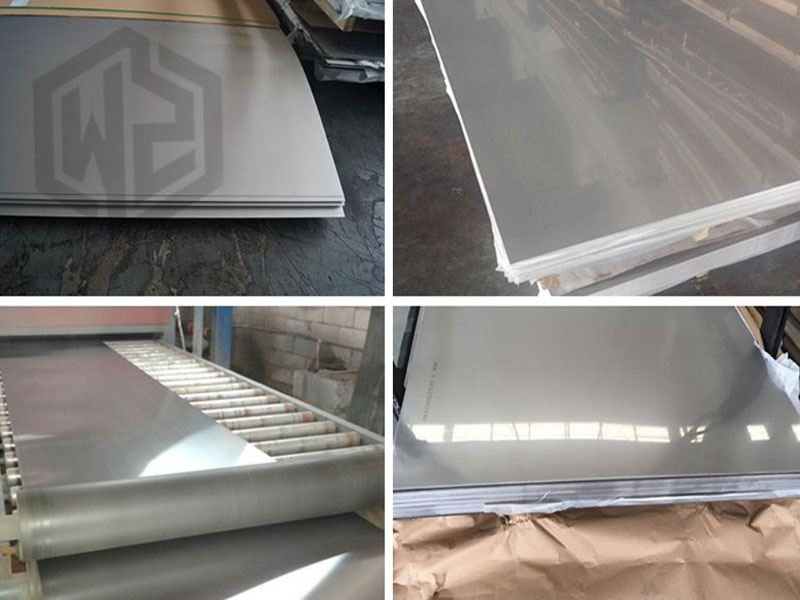

Original Finish Stainless Steel

Also known as the rolled finish, this is the surface condition directly obtained after the final rolling process. It features a dull, coarse texture with a granular appearance and represents the most fundamental surface of stainless steel.

- Representative: No. 1 Finish

- Grades: Most commonly found in general austenitic grades.

- Applications: Primarily used in industrial sectors such as chemical equipment and storage tanks—semi-finished products requiring no aesthetic appeal or further processing.

Dull Finish Stainless Steel

Achieved by cold rolling followed by heat treatment, acid pickling, and light grinding or brushing of the surface. Presents a subdued silver appearance, smoother than the raw surface (No. 1) yet retaining a matte finish with lower gloss than 2B surfaces.

- Representative: 2D Finish

- Grades: 304/304L, 316/316L, etc.

- Common Applications: Deep-drawn components, chemical processing equipment, food processing machinery, and other industrial uses where surface gloss is not critical.

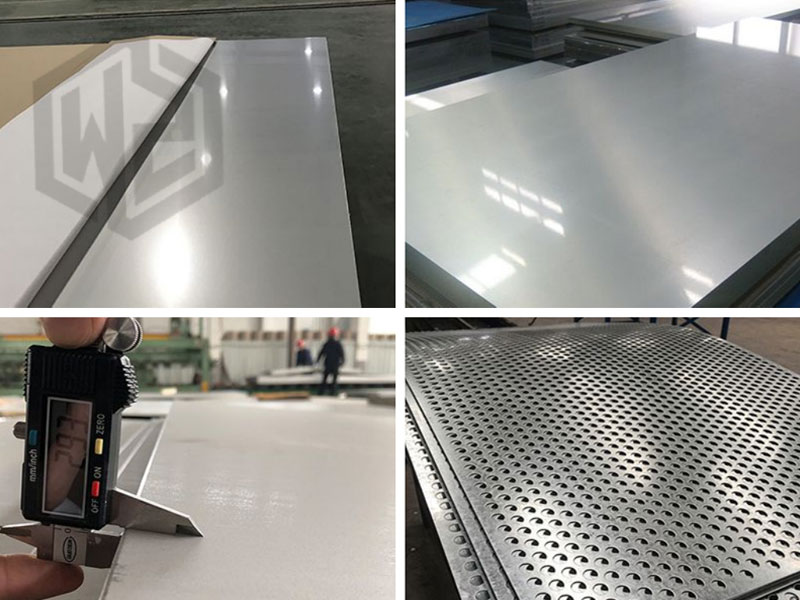

Matte Stainless Steel

Features a soft, low-gloss, non-reflective texture that effectively conceals fingerprints, minor scratches, and stains.

- Grades: 304, 430, etc.

- Common Applications: Home appliances (e.g., refrigerators, ovens, refrigerator panels, dishwasher panels), catering equipment, medical devices, architectural interior finishes

Satin Stainless Steel

Also known as “brushed” or “hairline” finish, achieved through mechanical polishing (using medium-grit abrasives) to create fine, short, non-directional brushed lines. It effectively conceals minor scratches and fingerprints while offering superior wear resistance compared to mirror finishes, making it a highly popular decorative surface.

- Grade: 304

- Common Applications: Elevator cabs, architectural trim, hotel fixtures, appliance panels, commercial kitchen equipment, and sinks.

Polished Stainless Steel

Based on processing techniques, polished stainless steel ranges from low-gloss standard polishing to high-gloss fine polishing. Its surface achieves extreme smoothness with exceptionally high reflectivity, requiring frequent cleaning and maintenance.

- Grades: 304 (8K mirror finish), 316

- Common Applications: Highly decorative fields, components in jewelry, tableware, and premium accessories; hotel lobbies; sculptures; high-end appliances; furniture; and catering utensils.

Mirror-Finished Stainless Steel

A type of polished stainless steel achieved through multiple precision polishing processes, resulting in a surface with mirror-like high reflectivity. The flawlessly smooth mirror finish facilitates easy cleaning and maintenance, minimizing hiding spaces for dirt and bacteria.

- Representative grades: 6K, 8K

- Common applications: High-end architectural decoration, luxury hotel lobbies, boutique display cabinets, and automotive interiors.

Brushed Stainless Steel

Formed by grinding the stainless steel surface to create distinct linear (straight brushed), random (snowflake pattern), or swirling (spiral) textures. Combines the advantages of matte and polished finishes, but with more pronounced patterns than matte.

- Grades: 304, 316, 430.

- Common Applications: Home appliances (range hoods, ovens), electronic casings (phones, tablets), elevator doors, kitchen appliances, door/window trim, brand signage, and furniture.

Bead Blasted Stainless Steel

High-velocity projectiles (e.g., sand particles) impact the stainless steel surface, creating a uniform, non-directional texture of minute pits. This process enhances surface adhesion for subsequent coating or plating. The finish exhibits a consistent matte gray appearance with a smooth tactile feel and zero reflectivity.

- Grades: 304, 316

- Common Applications: Outdoor sculptures, building exteriors and industrial equipment, interior design walls, door handles, appliance panels, and industrial products requiring a uniform matte finish.

Colored Stainless Steel

A colored oxide layer is formed on the stainless steel surface through chemical or electrochemical methods. Common colors include titanium black, sapphire blue, rose gold, and champagne gold. Compared to color-coated steel, colored stainless steel offers richer, more durable colors and superior corrosion resistance, though it carries a higher cost.

- Grades: 304, 316

- Common Applications: Architectural roofing and curtain walls, art installations, signage, and luxury goods decoration.

PVD-Coated Stainless Steel

Description: A high-tech process utilizing physical vapor deposition in a vacuum environment to vaporize target materials (e.g., titanium, zirconium, chromium) and deposit them onto stainless steel surfaces.

- Grade: 304

- Common Applications: High-end hardware (faucets, door locks), automotive trim, watch cases and bracelets, medical instruments, and decorative strips for luxury appliances.

Etched Stainless Steel

Utilizes chemical or laser techniques to engrave intricate patterns, logos, or textures onto stainless steel surfaces. Enables exceptionally fine and complex designs with unique artistic appeal and customization.

- Grades: 304, 316, 430

- Common Applications: Decorative panels, brand logos, elevator door panels, art prints, premium tableware, and customized gifts.

Embossed Stainless Steel

A mold or roller is used to create raised or recessed three-dimensional textures on the stainless steel surface (e.g., diamond patterns, orange peel textures, wood grain imitations). This process enhances decorative appeal, rigidity, scratch resistance, and slip resistance. Beyond enriching visual depth, it improves tactile feel and functionality. Embossed stainless steel is widely used in architectural curtain walls, interior decoration, and packaging materials, showcasing distinctive textures and styles.

- Grades: 304, 201, 430.

- Common Applications: Elevator cab interiors, accent walls, cabinet doors, station platforms, anti-slip flooring.

The diverse surfaces of stainless steel unlock limitless possibilities across various fields. Whether prioritizing functionality in industrial settings or aesthetics in decorative applications, Wanzhi Group delivers tailored solutions for real-world needs. Contact us for a complimentary quote!