Standing seam metal roofing is a building material widely used in large-span roofing systems for industrial plants, commercial buildings, public facilities, and high-end residences. It features waterproofing, wind resistance, and exceptional durability. Based on panel systems, it can be categorized into various types including standing seam systems, classic cap systems, flat lock systems, flat panel systems, profiled sheet systems, and unit panel systems. By coating type, they fall into two categories: metal-coated and color-coated.

Classification by Jointing Method (Panel System)

Panel type classification is the most fundamental categorization for standing seam metal roofing, as it directly determines the roof’s appearance, waterproofing performance, structural characteristics, and application scope. Wanzhi Group offers finished products and raw materials for the following panel types. Contact us for a quote.

Standing Seam System

In this system, adjacent panel edges are rolled upward and interlocked using specialized seamers, forming a continuous longitudinal seam up to several dozen millimeters high. This system delivers exceptional waterproofing and outstanding wind uplift resistance, making it ideal for large-span structures like stadiums and airports with stringent waterproofing and wind resistance requirements. It is also the mainstream system for large public and industrial buildings today.

Batten Cap System

The Batten Cap System involves installing a base panel with clips, then covering it with a separate, decorative cap. It offers strong three-dimensional appeal and decorative value, with caps that can be independently removed for easy maintenance and inspection. Suitable for high-end office buildings, hotels, theaters, historic building restorations, and other structures prioritizing aesthetic appeal and functionality.

Flat Lock System

The Flat Lock System utilizes square or diamond-shaped metal panels that interlock via edge-bent hooks, forming a flat roof or wall surface. This interlocking method offers exceptional decorative potential, enabling complex patterns, facade effects, irregular curves, and sculptural forms. Widely used in: building curtain walls, high-end interior/exterior decoration, and decorative roof areas where artistic impact is paramount.

Cassette Panel System

The Cassette Panel System utilizes metal panels with folded edges, mechanically fixed to the framework via concealed hangers to create a large, flat surface. This panel type offers an exceptionally smooth appearance, structural stability, and high rigidity. It is widely applied in modernist architectural curtain walls, interior ceilings, and large-scale interior surfaces where ultimate flatness is pursued.

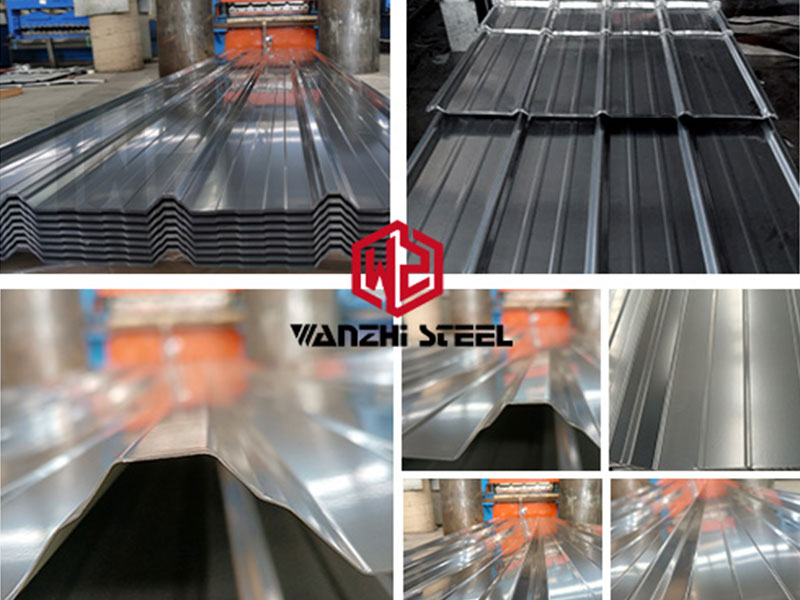

Corrugated / Trapezoidal Profile System

The corrugated/trapezoidal profile system utilizes roll-formed wavy or trapezoidal panels, representing the most cost-effective roofing solution. These panels offer low material costs, rapid installation, and excellent drainage and wind resistance. However, screw-penetration fastening compromises the roof’s integrity, resulting in relatively lower waterproofing reliability and weather resistance. They are primarily suited for cost-sensitive functional buildings such as industrial plants, warehouses, and agricultural structures.

Unitized Panel System

The unitized panel system integrates panels, insulation layers, and waterproofing layers into complete modules during factory fabrication. These modules are directly hoisted and hung onto the main structure on-site. Characterized by the fastest installation speed and high precision, it is widely used in budget-sufficient, high-rise buildings and modular constructions demanding rapid installation.

Classification by Material

The material composition of metal panels determines their corrosion resistance lifespan, cost, strength, and color retention. Currently, Wanzhi Group’s popular materials include galvanized steel, aluzinc, zinc-aluminum-magnesium alloy, color-coated galvanized steel, color-coated aluzinc, and aluminum alloy.

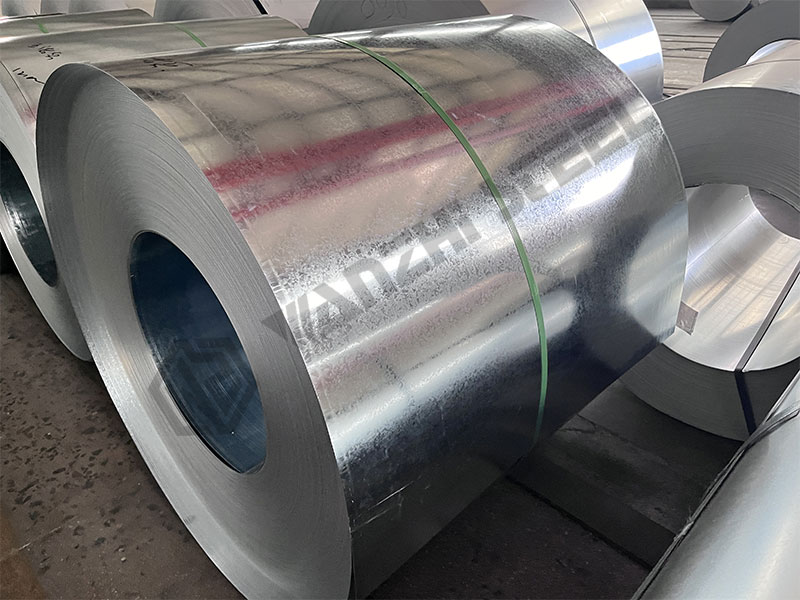

Galvanized Steel (GI)

Galvanized steel is produced by hot-dip galvanizing cold-rolled steel substrates. It offers low cost and high strength. Through cold forming, it can be shaped into various profiles. The surface zinc coating can be customized for specific environments, with popular grades ranging from Z80 to Z275. Primarily used for non-exposed structural components in construction, such as base-layer profiled steel sheets or backing plates.

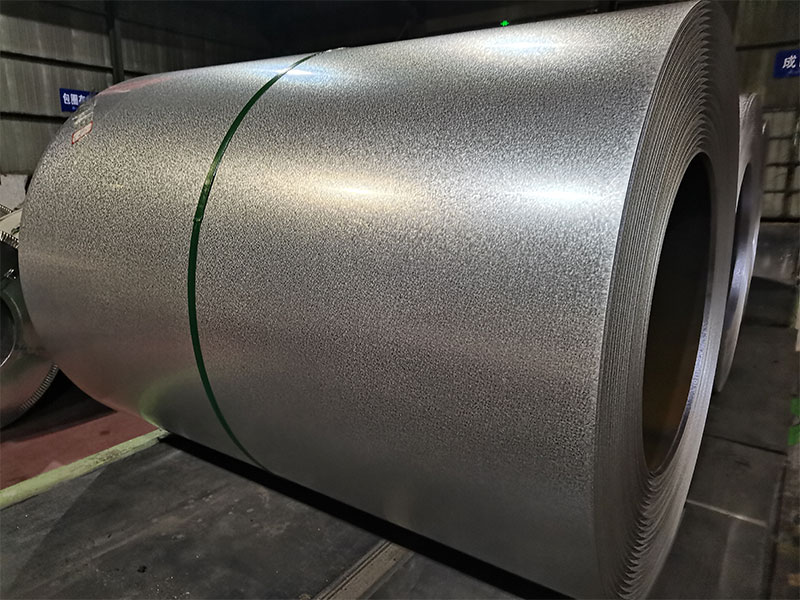

Galvalume/Aluzinc Steel (GL)

Galvalume steel represents an upgraded version of galvanized steel, featuring an alloy coating composed of 55% aluminum, 43.4% zinc, and 1.6% silicon. Its comprehensive performance significantly surpasses standard galvanized sheets, offering corrosion resistance and heat tolerance 2-6 times greater than galvanized steel. It is suitable for most construction environments.

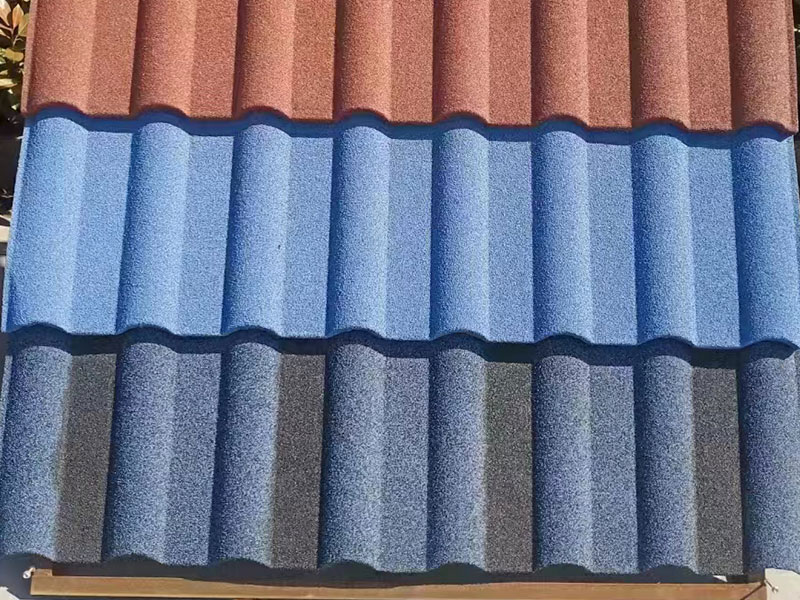

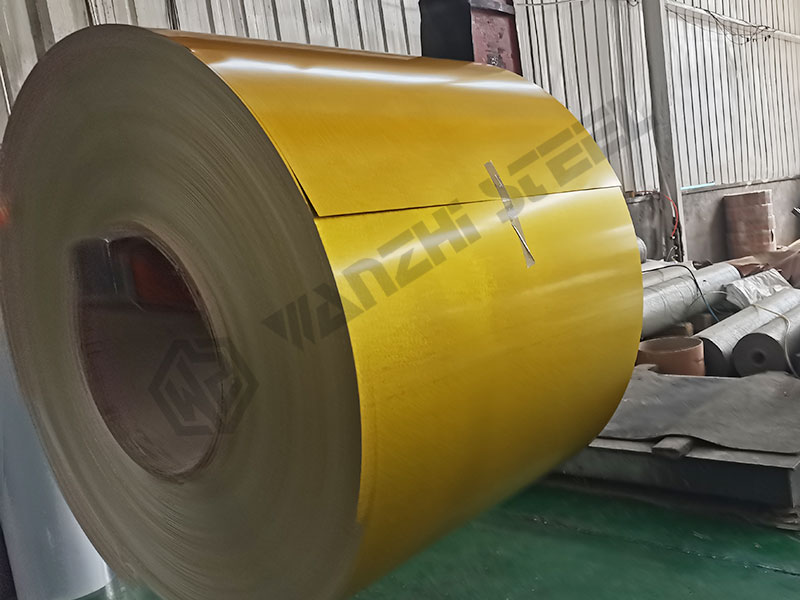

Pre-painted Galvanized Steel (PPGI)

Pre-painted galvanized steel PPGI uses galvanized steel as its base material, with a surface coating applied. It offers a wide variety of colors and patterns, enhancing decorative appeal while retaining the properties of galvanized steel. It is suitable for most outdoor building roofs and applications with high cost and control requirements.

Pre-painted Galvalume Steel (PPGL)

Pre-painted Galvalume steel PPGL is a colored coated steel sheet produced by applying a surface coating to Galvalume steel. It combines the corrosion resistance, weather resistance, heat reflectivity, and decorative qualities of Galvalume steel with organic coatings, making it the absolute mainstream material for high-end metal roofing.

Aluminum Alloy Panels

Aluminum alloy panels are lightweight with exceptional corrosion resistance and can be easily formed into complex curved surfaces. Though their material cost exceeds that of Galvalume steel, their superior overall performance makes them ideal for projects demanding weight reduction and intricate designs.

Titanium-Zinc Sheets

Renowned for their exceptionally long lifespan and unique self-healing properties, titanium-zinc sheets require no painting maintenance. They represent a noble and enduring natural material.

Copper Sheets

Copper sheets are the pinnacle of luxury in architectural metals. Their appearance oxidizes and changes color over time, eventually developing a classic patina. With an extremely long lifespan, they are frequently used to create iconic buildings with artistic and historical significance.

Application Selection

So how can we choose the most suitable and cost-effective combination from the wide array of panel types and materials for our project? Wanzhi Group has compiled a simple summary based on building types and application environments. We hope our recommendations will assist you in making your selection.

Select by Building Type

- Large-span public buildings: Recommended Standing Seam System + PPGL (PVDF coating)

- High-end commercial buildings: Recommended Classic Standing Seam System or Flat Panel Strip System + PPGL/PVDF or Aluminum Alloy

- Cost-priority industrial roofing: Recommended Roll-formed Panel System + PPGI/PPGL (SMP/PE Coating)

- Decorative walls/roofs: Recommended Flat Locking System + Titanium-Zinc Sheet, Copper Sheet, or PPGL

Material Selection

- Standard environments, cost-performance focus: Recommended PPGL (HDP/SMP coating)

- Harsh environments (coastal, industrial zones): Recommended PPGL (PVDF coating) or Aluminum Alloy

- Ultimate longevity, unique aesthetics: Recommended Titanium-Zinc Sheet, Copper Sheet

- Concealed structural layer/backing: Recommended Galvanized Aluminum-Zinc Sheet (GL)