What is a Steel Strip?

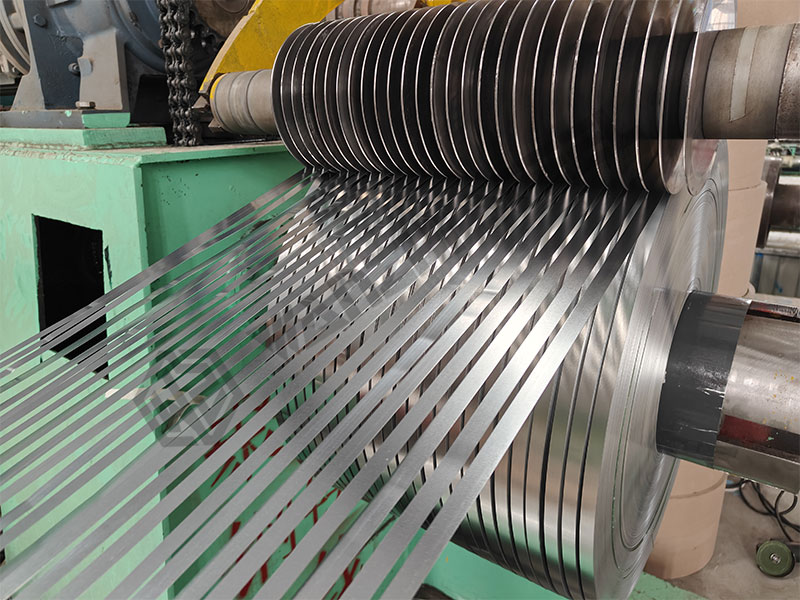

Strip steel is a thin, narrow, and long sheet of steel with a width of up to 1300mm, narrow strip for widths up to 600mm, and wide strip for widths over 600mm. It is processed by the rolling process and used as a raw material in a wide range of industrial manufacturing applications. Wanzhi Group‘s steel strip is supplied in 3–8 tons of coils each.

What are the Types of Metal Strips?

There is a wide range of strips, which can be divided into hot rolled strips, cold rolled strips, metal coated strips, color coated strips, alloy strips, stainless steel strips, and so on, according to the production process, material, and surface treatment.

Materials

- Carbon Strip: Strip made from carbon structural steel through a cold or hot rolling process.

- Coated Strip: Steel material made from coated steel coil (GI, GL, ZAM, PPGI, PPGL, AL, etc.), slit into strips.

- Stainless Steel Strip: A narrow and long ultra-thin stainless steel sheet, slit from stainless steel coil.

- Electrical Strip: A soft magnetic alloy of silicon and iron with a carbon content of less than 0.005%, also known as silicon steel sheet and silicon steel sheet.

Processes

- Hot Rolled: Rolled at high temperature with a relatively rough surface.

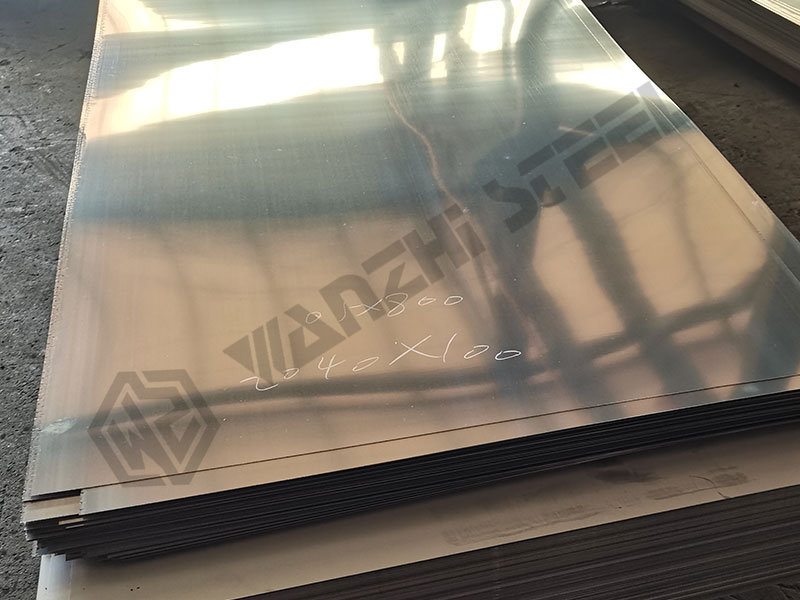

- Cold Rolled: Rolled at room temperature with a smooth surface.

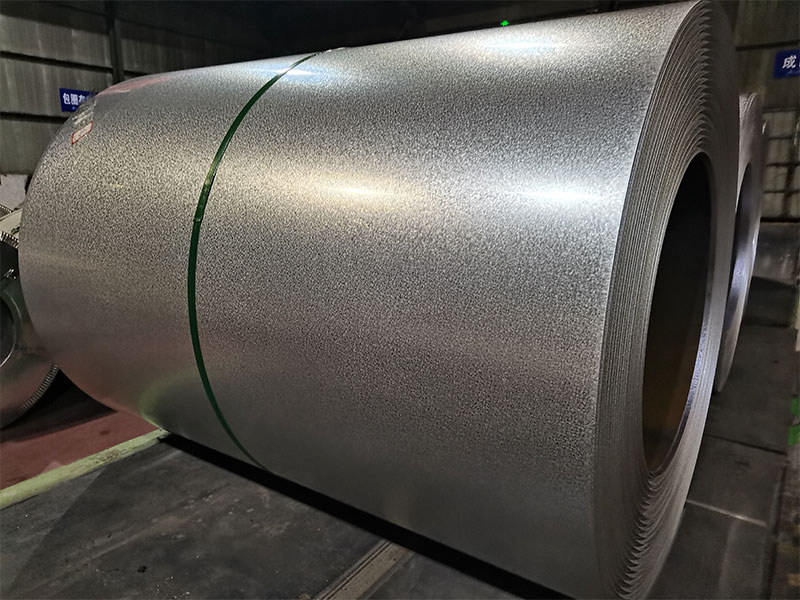

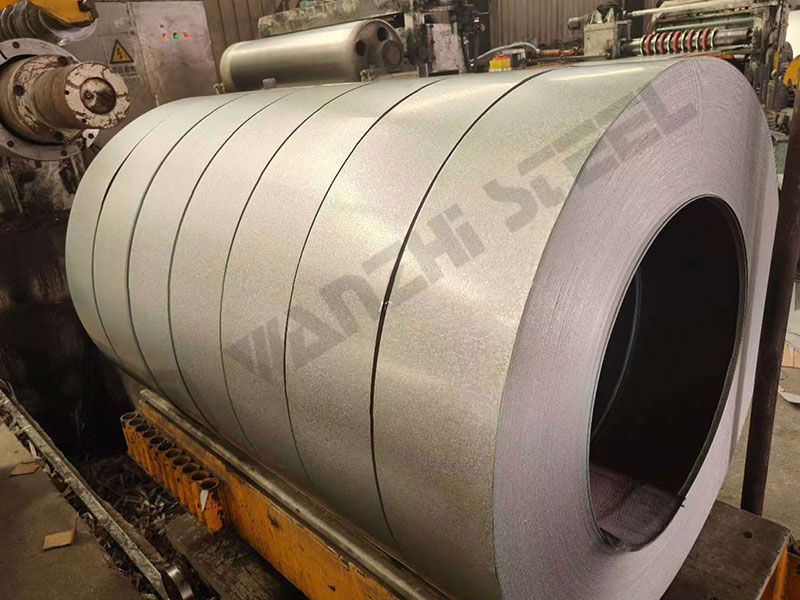

- Galvanized: Made by hot dipping or electroplating process, with smooth surface, or with spangle and other effects.

Surface Finishes

- Galvanized Strip: Strips coated with a zinc layer to provide corrosion resistance.

- Alloy Strip: Cold-rolled or hot-rolled steel strips are coated with an alloy layer, such as zinc-aluminum alloy, zinc-aluminum-magnesium alloy, aluminum, tin, etc., to improve the performance and prolong the service life of the steel.

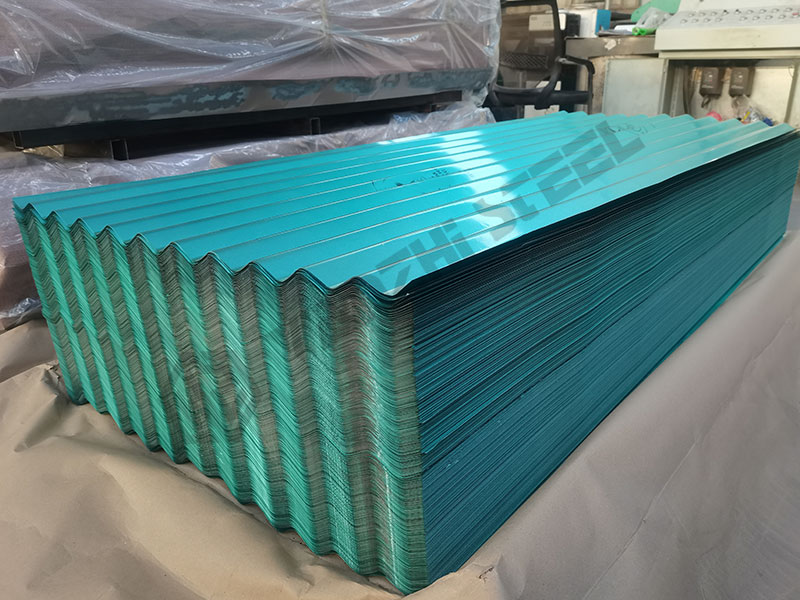

- Color-Coated Strip: The surface is roll-coated with one or more layers of organic paint to enhance corrosion resistance, weather resistance, and aesthetics.

- Polishing: One of the surface treatments of stainless steel strips, to enhance its aesthetic and stain resistance.

Why Use Metal Strip?

Strip steel has a wide range of raw materials, including carbon steel, carbon structural steel, spring steel, tool steel, stainless steel, etc. In addition, the toughness and processability of strip steel can be made into a variety of steel products, and after surface treatment, it can be used as a raw material for steel products processing, construction, industry, machine building, packaging, energy, electronics, and other fields.

Advantages of Steel Strip

- Good toughness and workability

- Good adaptability

- Light weight

- Various surface treatments

- Smooth and flat surface

- High precision

Uses of Strip Steel

- Carbon steel strip: Mechanical structures, raw materials such as steel profiles/tubes, metal products, etc.

- Coated steel strip: construction, automobile, home appliances, transportation, etc.

- Stainless Steel Strip: Food, medical, electrical appliances, etc.

- Electrical steel strip: electric motors, power transformers, etc.

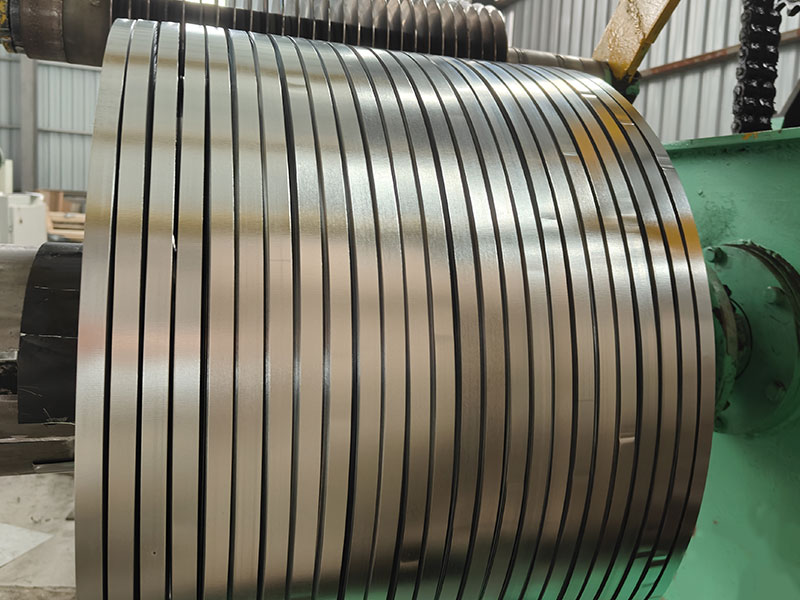

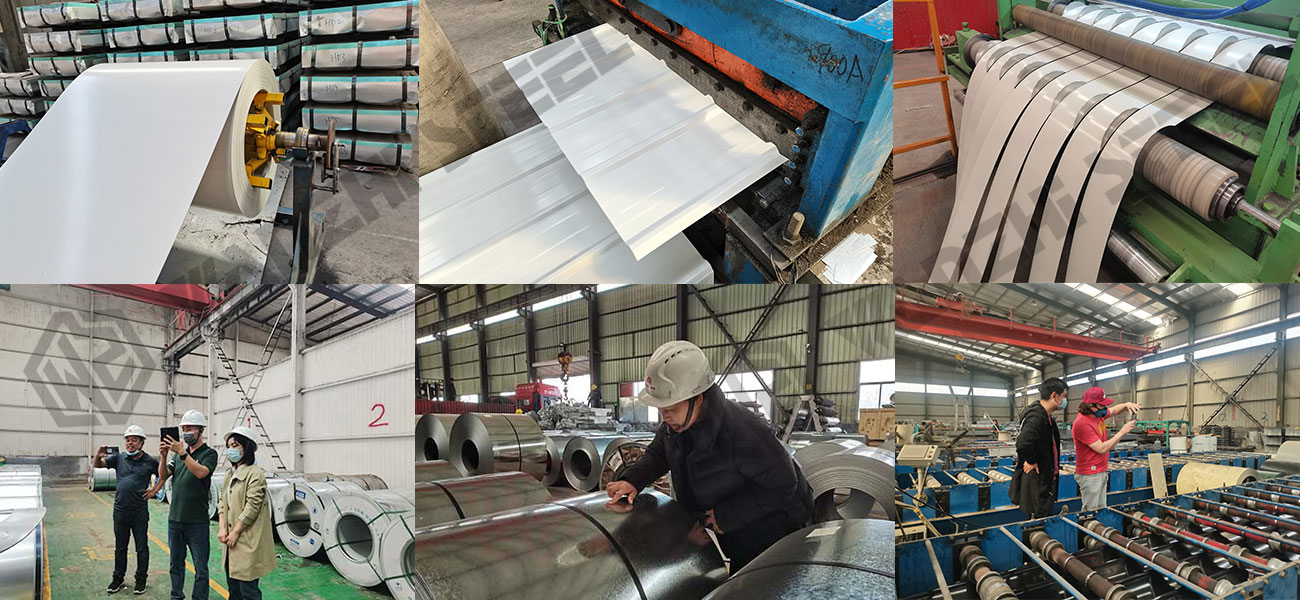

Strip and Split Strip – Factory

Wanzhi Group has high precision slitting equipment in its factory, producing cold rolled slitting, galvanized slitting, electrical steel slitting, stainless steel slitting, color coated steel slitting with thickness 0.15-2.5mm and width accuracy ±0.1mm. We provide professional strip solutions for automotive, electronics, home appliances, and other manufacturing industries.

Production

- Raw materials: carbon steel, structural steel, tool steel, stainless steel, and so on.

- Hot Rolling: The billet is heated at high temperatures and fed into the hot rolling mill for hot rolling.

- Cold Rolling: The hot rolled steel is cold rolled at room temperature.

- Surface treatment: According to the use, choose the appropriate surface treatment, galvanized, painted, alloyed, polished, etc.

- Slitting: The coils are put into slitting machines for slitting.

- Quality inspection: After surface inspection and physical property test, the coils will be packed and put into the warehouse.

Factory

Wanzhi Factory is located in Binzhou City, Shandong Province, China. Besides slitting equipment, we also have a galvanizing production line, an alloying production line, and a color-coating production line. So far, we have received customers from more than 40 countries.

Products

Wanzhi Group does not only provide strips of various materials and applications, but also offers raw steel materials for different projects, such as galvanized steel, ZAM steel, aluminized zinc coated steel, color coated steel, stainless steel, colored aluminum, cold rolled and hot rolled steel coils and sheets, as well as finished products: steel wires, steel tubes, metal panels, steel constructions, and so on. If you need more information or samples of steel, please feel free to contact us.