Value-Added Processing

Laminated: Provides additional surface protection for metal materials, suitable for high-end surface requirements.

Embossing: Enhances the aesthetics, wear resistance, and scratch concealment of metal materials.

Slitting: Cuts wide coils into narrow strips of specific widths, preparing them for subsequent processing.

Flat Rolling: Flattens metal coils and shears them into flat sheets of specified dimensions for direct use.

Roll Forming: Rolls coils or sheets into structural roof panels or wall panels for direct use in building envelope systems.

Coating: Applies colored coatings to cold-rolled, galvanized, or aluminum alloy substrates to produce color-coated sheets (PPGI, PPGL, PPAL, etc.).

Punching/Cutting: Produce components with holes or specific shapes, integrating functionality and decoration.

Light Steel Stud Forming: Directly process into structural stud components for building construction.

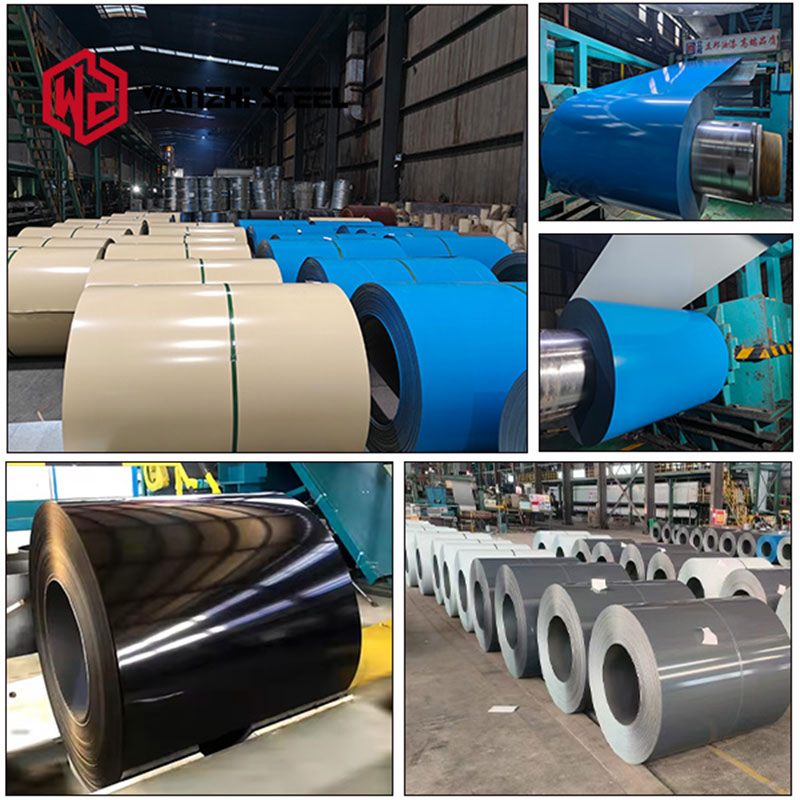

Raw Materials Factory

Beyond these additional services, Wanzhi Group operates an advanced, comprehensive metal materials production base integrating R&D, manufacturing, and testing. Covering the entire industrial chain from cold-rolled substrates to various coated finished products, we deliver stable supply, premium steel quality, and significant cost advantages.

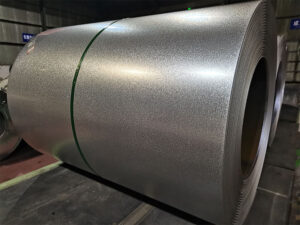

Galvanized Steel Production Line: Products cover a wide range of coating requirements from Z30 to Z600. Surface treatments include chromate passivation, chromate-free passivation, and oil coating. Capable of producing galvanized coils in various grades from DX51D to DX54D, ranging from commercial-grade to ultra-deep-drawing grades.

Galvalume/ZAM Production Line: Upgraded GI steel coating, featuring 55% aluminum-zinc alloy (GL/AZ) and zinc-aluminum-magnesium (ZAM) coating production lines.

Painting Production Line: PPGI/PPGL/PPAL production line featuring a fully automated two-coat, two-bake process equipped with a precision three-roll coating system, inline inspection equipment, and UV curing technology. Products encompass multiple high-performance coating systems including PE, SMP, HDP, PVDF, PVC, and PU, achieving diverse visual effects such as high gloss, matte, textured, and printed finishes.

Stainless Steel Production Line: Products include 200 series, 300 series, and 400 series. Surface finishes include 2B, BA, No.3 (hairline), No.4 (brushed), HL (satin), and 8K (mirror) finishes.

Powder Coating Production Line: Utilizing electrostatic spraying technology, this line achieves diverse special textures and tactile sensations.

Choose Us

Integrated Production: From cold-rolled substrates to high-end coated finished products, our factory maintains vertical integration for quality control.

Scale Production: Seven parallel production lines with an annual capacity of 600,000 tons ensure stable supply for bulk orders.

Technical Support: Wanzhi Factory houses a comprehensive laboratory and testing center, enabling end-to-end quality monitoring of incoming materials and finished products.

Customization Flexibility: We support customized production of non-standard products according to client specifications, offering OEM/ODM services with lead times ranging from 5 to 45 business days.

Hot Products

Wanzhi Group provides one-stop steel services. We are not just a supplier, but your trusted partner for metal material solutions.