Cold galvanization is a common metal anti-corrosion surface treatment technology for small and medium-sized components, indoor equipment, general application environments, and high-end manufacturing sectors. Alongside hot-dip galvanizing, it is regarded as a primary processing method for galvanized steel. Today, let’s comprehensively explore cold galvanizing from multiple dimensions including definition, standards, appearance, and process.

Definition of Cold Galvanization

Cold galvanization, also known as “electrogalvanizing” or “cold-dip galvanizing,” is a process that deposits a layer of metallic zinc onto carbon steel surfaces at ambient temperatures through electrolysis. This process primarily utilizes electric current to drive zinc ions from a zinc salt solution to migrate directionally onto the metal substrate surface, forming a uniform and dense zinc layer to achieve substrate protection. Electrogalvanizing, as an efficient, precise, and economical rust prevention process, is widely favored for its high precision and excellent appearance.

International Standards for Electrogalvanizing

Wanzhi Group produces electrogalvanized steel and products compliant with international standards such as GB, ASTM, JIS, ISO, DIN, and other international standards.

- GB (Chinese National Standard): GB/T 9799-2011 – Equivalent to ISO 4042 standard; GB/T 15675 – Steel sheets and strips with continuous electrogalvanized or zinc-nickel alloy coatings, etc.

- ASTM (American Society for Testing and Materials): e.g., ASTM B633 – Standard Specification for Electrogalvanized Steel, ASTM A591 – Electrogalvanized Steel Sheets and Tins, etc.

- ISO (International Organization for Standardization): e.g., ISO 2081 – Metal coatings – Electrogalvanized steel. ISO 4042:2018 – Defines technical requirements for electrogalvanized coatings.

- JIS (Japanese Industrial Standards): e.g., JIS H 0401 – Inspection methods for electrogalvanized coatings; JIS G3313 – Electrogalvanized steel sheets and strips.

- DIN (German Institute for Standardization): e.g., DIN EN ISO 2081 (identical to ISO).

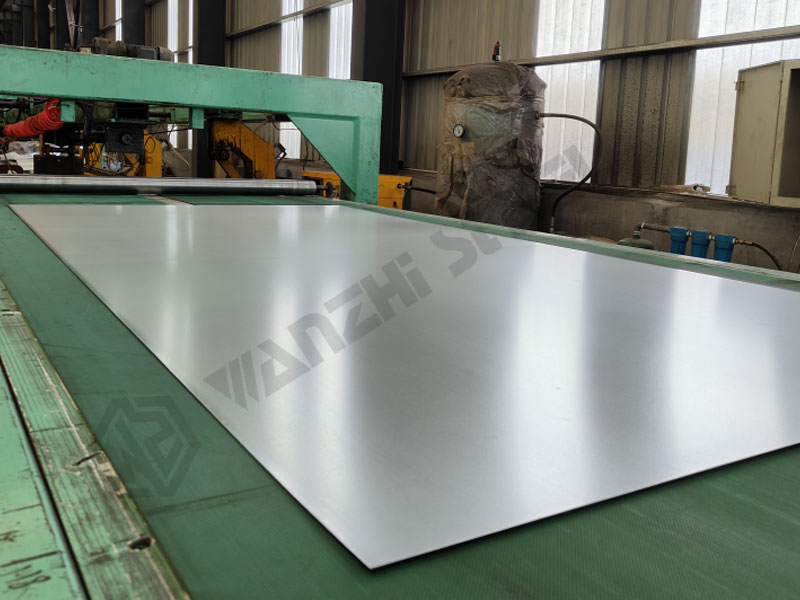

Appearance of Cold-Galvanized Surfaces

Cold-galvanized surfaces exhibit exceptional smoothness, uniformity, and fineness, displaying a slightly bluish-white metallic sheen. Subsequent passivation treatments enable diverse aesthetic finishes.

- Color: Pure cold-galvanized coatings typically appear light bluish-white or silver-gray with a soft luster. After passivation, they can exhibit iridescent, deep black, pale yellow, or colorless effects.

- Surface Condition: A high-quality cold-galvanized coating surface should be uniform, smooth, and free of noticeable particles, bubbles, pinholes, or missed coating areas.

Cold-Galvanized Coating Thickness

The zinc coating thickness on galvanized steel determines its corrosion resistance lifespan. Cold-galvanized coatings typically range from 60-400 g/m², thinner than hot-dip galvanized steel (HDG: 30-600 g/m²). Of course, the coating thickness should meet the project’s “corrosion protection requirements”—thickness alone does not guarantee superior performance.

- Standard Corrosion Protection: Zinc layer thickness typically 5-12μm

- Moderate Corrosion Protection: Zinc layer thickness must reach 12-20μm

- High Corrosion Protection: Zinc layer thickness must be ≥20μm

Process Flow of Cold Galvanizing

The typical cold galvanizing process consists of three major stages: pretreatment, electroplating, and post-treatment.

- Degreasing: Removes oil contaminants from the steel coil surface.

- Acid Pickling: Removes surface scale (rust).

- Activation Treatment: Enhances zinc ion adhesion.

- Electrogalvanizing: Deposits zinc ions onto the steel surface to form a zinc layer.

- Passivation: Immediately passivates galvanized steel components to enhance corrosion resistance.

- Drying: Removes surface moisture.

- Inspection: Product quality is verified through visual inspection (appearance), magnetic thickness gauge (coating thickness), cross-hatch adhesion test (adhesion), and salt spray test (corrosion resistance).

Characteristics of Cold Galvanizing

High precision and conformability: Extremely thin and uniform coating, ideal for precision components and fasteners.

Superior appearance: Electrochemically deposited zinc provides a smooth, lustrous surface suitable for visible applications or as a substrate for PPGI Steel.

Excellent corrosion resistance: Zinc layer offers dual protection through “cathodic protection” and “barrier protection.”

Superior Processability: Strong coating adhesion allows deep processing like bending, stamping, and riveting without peeling.

Cost-Effectiveness: For thin coatings and small parts, cold galvanizing often offers better value than hot-dip galvanizing.

Applications of Cold Galvanizing

Automotive Industry: Bolts, nuts, instrument panel brackets, etc.

Electronics & Appliances: Computer cases, hard drive components, router housings, server racks, etc.

Construction & Hardware: Light-gauge steel framing, air conditioning brackets, shelving uprights, furniture hardware (hinges, screws), premium hardware fittings, lighting fixtures, scaffolding couplers, fencing.

High-End Furniture: Metal furniture components requiring refined aesthetics and rust resistance.

Limitations of Cold-Dip Galvanizing

Relatively Short Corrosion Resistance Lifespan: Not suitable for prolonged exposure to highly corrosive environments (e.g., marine, chemical plants) or direct soil burial.

Coating Thickness Constraints: Cannot achieve the exceptionally thick coatings possible with hot-dip galvanizing, sacrificing long-term corrosion protection.

Extremely Demanding Pre-Treatment Requirements: Incomplete cleaning leads to coating defects, directly compromising corrosion resistance.

Unsuitable for Large, Heavy Components: Cold galvanizing typically uses “immersion” electroplating, making it difficult to accommodate large components in plating tanks.

The final choice between cold and hot-dip galvanizing depends on the end-use environment, expected lifespan, and budget. When your product demands strict dimensional tolerances, surface quality, and processing performance, cold galvanizing is undoubtedly the ideal choice. If you are seeking premium cold galvanized steel, please feel free to contact Wanzhi Group.