PPGI (prepainted galvanized iron) and PPGL (prepainted galvalume iron) strips are two of the most widely used color-coated metal strips in the industrial, commercial, agricultural, and light industrial sectors. Excellent durability, adaptability, aesthetics, and corrosion resistance make PPGI and PPGL strips one of the most cost-effective steel solutions.

What are PPGI Steel Strips?

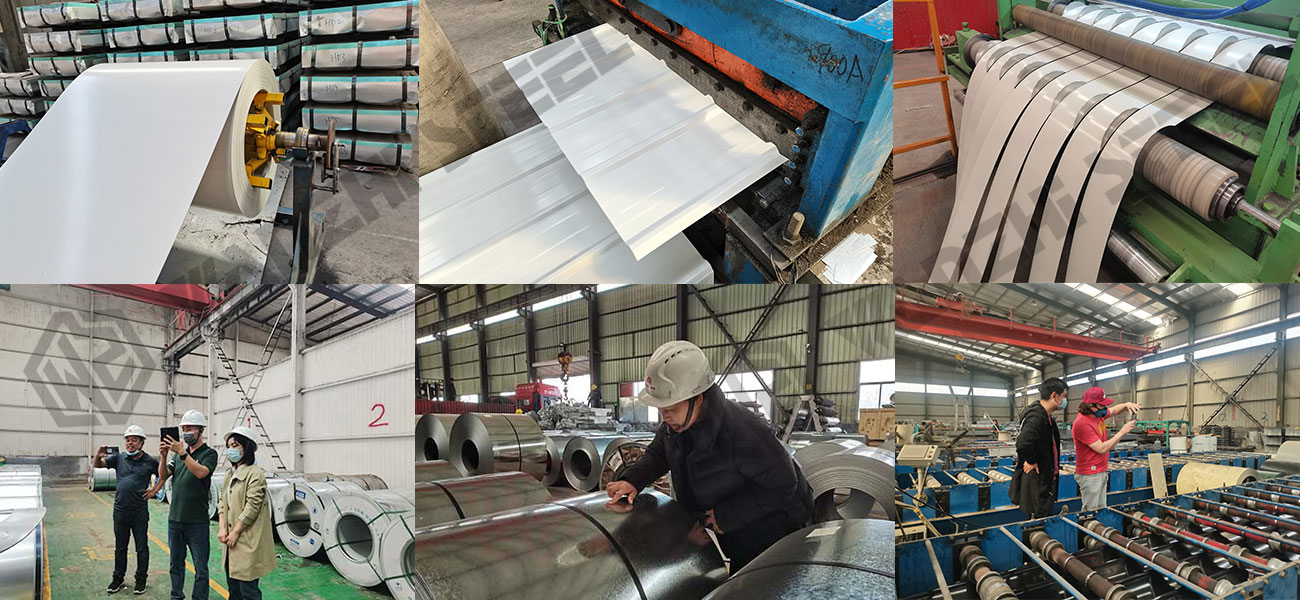

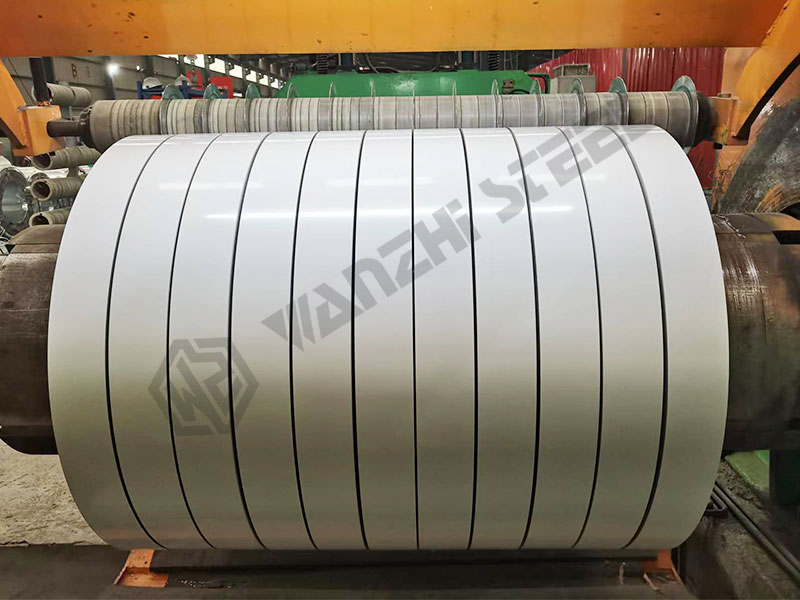

PPGI steel strips are strips of painted galvanized steel, usually supplied in coils. They are made from hot-dipped galvanized steel, coated with organic paint, and slit by a slitting machine.

PPGI Strips Process

- Galvanizing: A hot-dip galvanizing process that deposits a layer of zinc on the surface of the steel to protect against corrosion.

- Coating: One or more layers of colored PE/SMP/HDP/PVDF coatings are applied to the surface of the steel through a roller coating process.

- Splitting: The PPGI coil is fed into a slitting machine for slitting. Wanzhi production range: Thickness 0.15-2.5mm, Width 50-1650mm.

Advantages of PPGI Strips

- Corrosion resistance: The zinc and paint layers provide good protection against corrosion.

- Aesthetics: The painted surface can be customized with various colors and finishes for a decorative look.

- Durability: Galvanized and painted surfaces can maintain the steel’s performance over long periods in various applications.

- Low cost: Hot-dip galvanized steel is inexpensive to process, making hot-dip galvanized and painted steel strips more cost-effective than other materials.

- Versatile: Can be used outdoors or in wet environments.

What are PPGL Steel Strips?

PPGL steel strips are strips of hot-dip galvanized steel that are sold in coils. PPGL strips are made from hot-dip zinc-coated steel substrates that are rolled, painted, and slit into colored strips.

PPGL Strips Process

- Alloy Coating: A zinc-aluminum alloy coating of 55% aluminum and 43% zinc is applied to the steel surface.

- Coating: A colored coating is applied on top of the aluminized zinc alloy coating.

- Slitting: The finished PPGL coil is fed into a slitting machine for slitting.

Advantages of PPGL Strips

- Corrosion resistance: The zinc-aluminum coating and the paint coating provide greater corrosion resistance than PPGI strips.

- Aesthetics: Same color, finish, and surface structure as PPGI.

- Longer life: PPGL strips combine the advantages of aluminum zinc plating and paint to provide a longer service life outdoors.

- High Temperature Resistance: The aluminum element in PPGL strips provides improved high-temperature resistance.

What are PPGI Strips Used for?

PPGI steel strips are the most cost-effective solution for long-term exposure to the outdoors, or for applications where corrosion protection and appearance are important. PPGI strips are widely used in construction, home appliances, automobiles, furniture, agriculture, and other fields.

- Roofs, facades, door and window frames of outdoor buildings, etc.

- Refrigerator, laundry room, microwave oven and other home appliances sheet, electrical equipment, etc.

- Automobile body, interior decoration, etc.

- Outdoor furniture manufacturing materials.

- Greenhouse roofing and steel structures, farms, warehouses, etc.

What are PPGL Strips Used for?

PPGI steel strips are the best solution for steel products that need to be exposed to high temperature, humidity, and corrosive gas environments.

- Roofs, walls, facades, curtain walls, etc. in high-temperature and corrosive environments.

- High-temperature electric appliance housings.

- Equipment housings that are exposed to high temperatures and humidity for long periods.

- Heat-resistant parts of automobile, chassis.

- Outdoor furniture and decoration in humid and high-temperature environments.

- Tropical, subtropical, seaside, industrial area greenhouse materials, cold storage facilities.

Why Use PPGI Strips?

PPGI strips have excellent corrosion resistance, a good appearance, and are easy to mold, and can be used in a variety of manufacturing industries that require precision machining.

- PPGI strips are effective in preventing rust and corrosion in wet areas.

- PPGI strips are coated to meet the appearance requirements of a variety of applications.

- Cutting, molding, welding, and other further processing are possible.

- PPGI‘s coatings are UV-resistant and maintain color stability in outdoor, sunny conditions.

- Compared with other color-coated strips, the cost is low.

Why Use PPGL Strips?

PPGL strips have stronger corrosion resistance, higher heat and weather resistance, and longer service life to meet the requirements of construction and industrial applications in extreme environments.

- PPGL strips are effective in preventing rust and corrosion of steel in coastal, chemical, and other extreme environments.

- The zinc-aluminum coating in PPGL provides the material with high-temperature resistance and long-term stability in high-temperature outdoor environments.

- PPGL strips for roofing panels, wall panels, piping, and steel structures have better durability and stability in extreme weather conditions such as high humidity, heavy rain, and snow.

- PPGL has a longer service life than PPGI.

PPGI Strips VS PPGL Strips

| Item | PPGI strips | PPGL strips |

| Coating | GI | GL |

| Anti-corrosion | Good | Excellent |

| Weather resistance | Good | Excellent |

| Heat resistance | Good | Excellent |

| Durable | Good | Excellent |

| Aesthetics | Good | Good |

| Cost | Low | High |

When to Choose PPGI Strips?

- Roof panel production

- Exterior Decoration Production

- Home Appliance Manufacturing

- Automotive Parts Production

- Furniture Production

When to Choose PPGL Strips?

- Industrial and commercial building materials

- Exterior wall coverings for coastal and tropical subtropical areas

- High-Temperature Applications

- Solar Panel Production

Customized PPGI PPGL Strips

Wanzhi Group is a PPGI PPGL steel manufacturer in China, we can customize all types PPGI PPGL strips for roofing, doors, windows, gutters, piping systems, steel structures, and so on. Leave a message to tell us the quality, specification, coating, paint, paint film, weight, thickness, width, and length of the strips you want, and get a free quote now!