PPGI Steel (prepainted galvanized steel) and PPGL Steel (prepainted galvalume steel)are both high-quality construction and production materials that differ in corrosion resistance, weatherability, and cost, but not in color or appearance, providing customers with more options for their projects depending on budget and cost.

What is PPGI and PPGI?

PPGI (pre-painted galvanized steel) and PPGL (pre-painted aluminized zinc plated steel) are two typical non-metallic color-coated steels, commonly used color coatings are PE, SMP, HDP, PVDF, with corrosion protection life of 10-25 years or more. Metallic-coated steels are galvanized, aluminized zinc, aluminized zinc, chrome-plated, tin-plated, etc.

PPGL: Roll or spray organic coatings on galvalume coils, also used in the construction, appliance, transportation, and decorative industries.

Difference between PPGI and PPGL

Which is Better PPGI and PPGL?

Both PPGI steel and PPGL steel are color coatings applied to a metal substrate, both have a wide range of colors and patterns, both are aesthetically pleasing and corrosion resistant, and both are lightweight and strong. However, among the color steel products, PPGI coil is more popular, it is more cost-effective and our customers mainly use it as general construction material.PPGI and PPGL have their application scenarios, if you don’t know how to choose, you can leave a message to us, and we will recommend you according to your market situation.

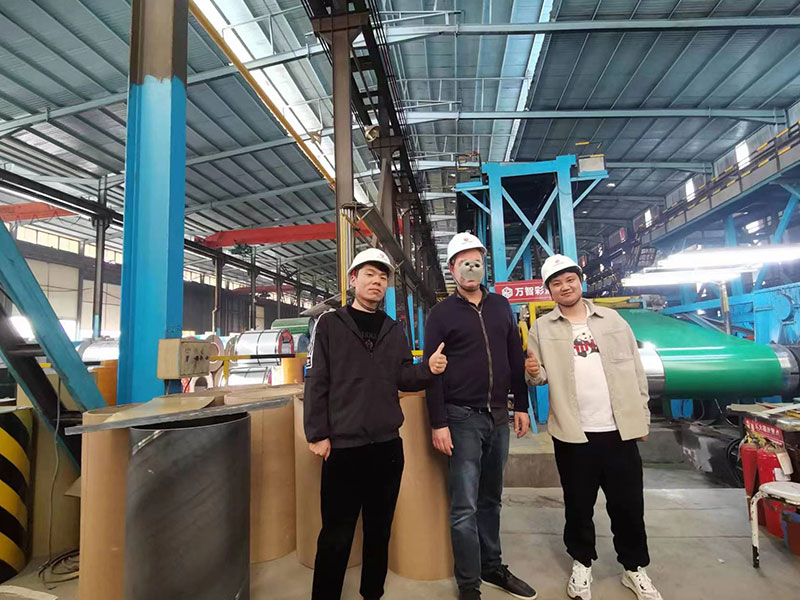

Where to Buy the PPGI and PPGL Steel?

If you already feel like buying color-coated steel PPGI or PPGL, then you are welcome to visit Wanzhi’s factory to see our color-coated production line. Whether it is product quality, availability, color pattern customization, price, or after-sales service, Wanzhi will be your reliable partner.

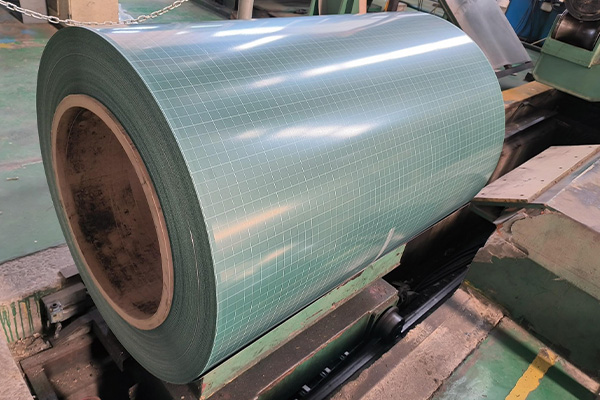

Color Coating Line

There are more than 150 kinds of printing patterns, GI/GL/SPCC/SPCD/SPCE/DC01-DC07/Q195, Q215, Q235 substrates, top coat 10–40 microns, primer 5-20 microns color coated steel can be customized.

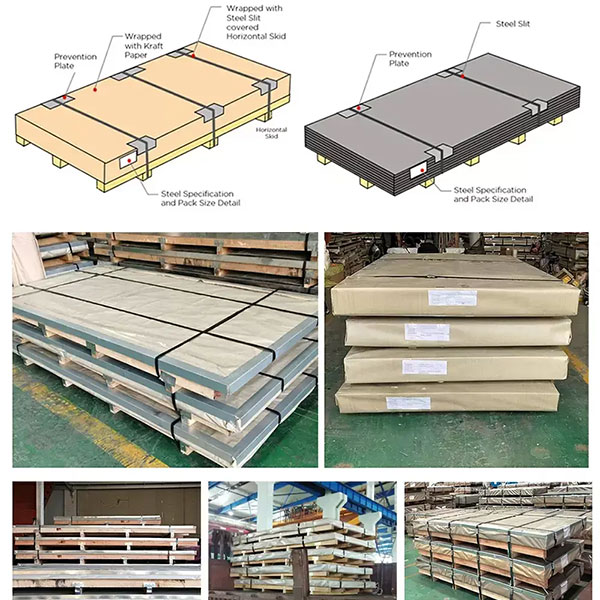

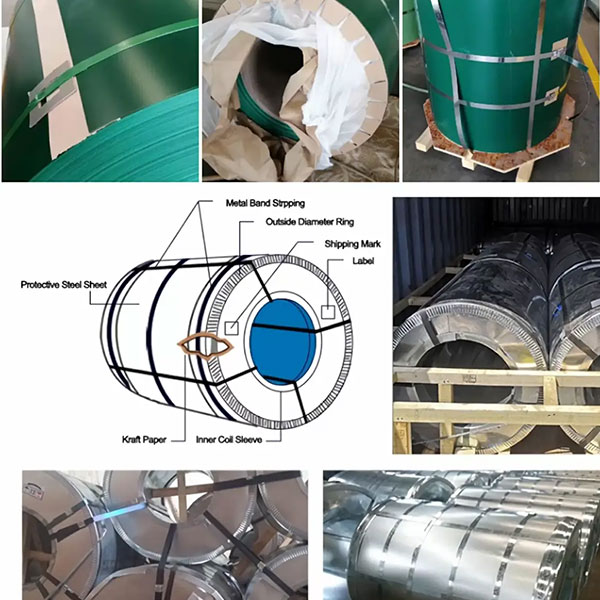

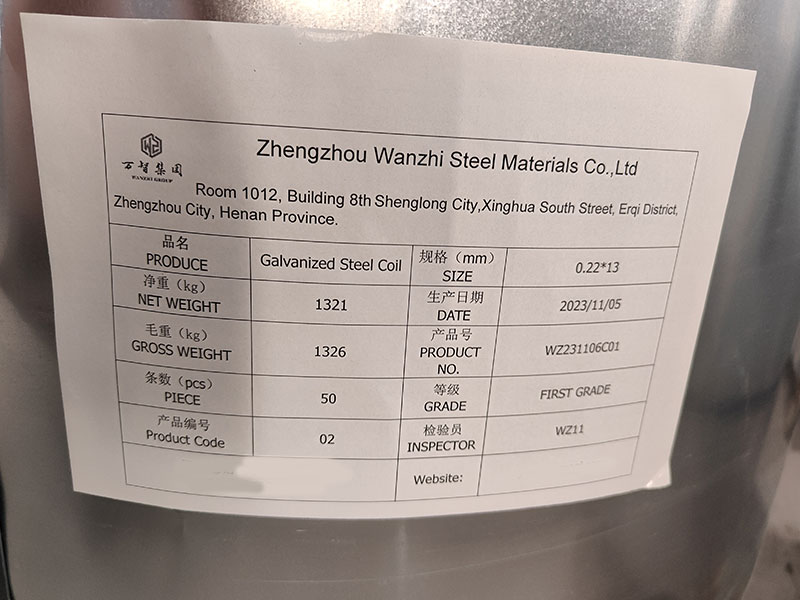

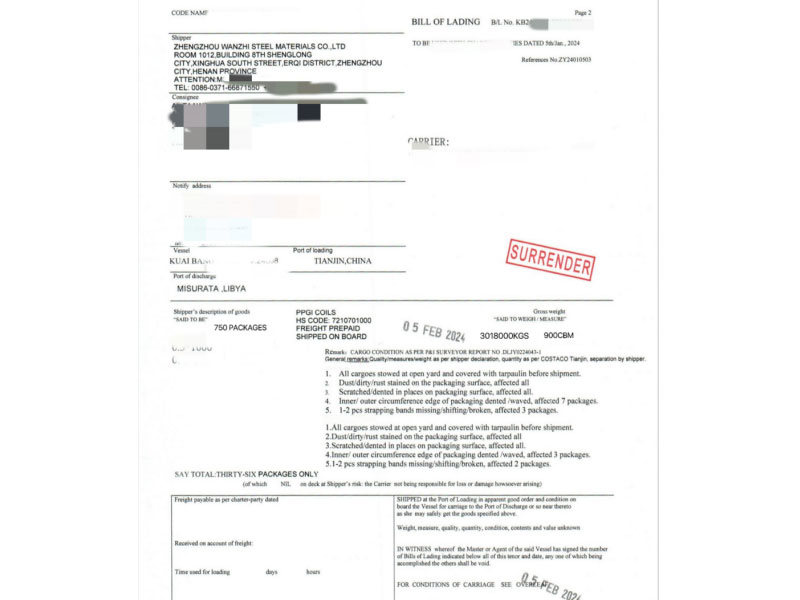

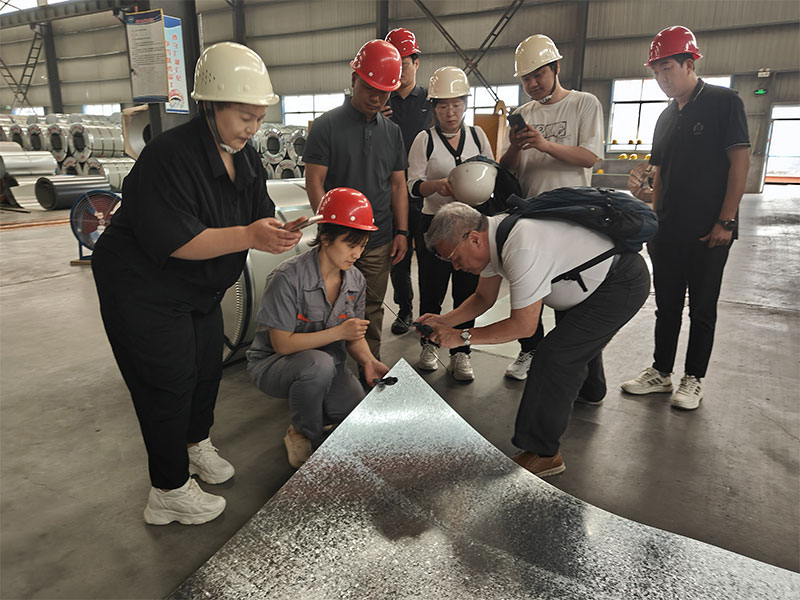

Inspection and Packing

Our PPGI/PPGL are packed and shipped after appearance inspection, thickness measurement, and corrosion resistance test, and are strictly packed according to export packing standards.