ZAM Steel Sheet, Zn-Al-Mg Coated Steel sheet, is widely used in the automotive, construction and energy sectors due to its excellent self-repairing and chip protection properties. Zn-Al-Mg Coated Steel Sheet is also an upgraded version of galvanized steel and an affordable alternative to stainless steel, making it an irreplaceable solution for high-end equipment manufacturing and construction.

ZAM Steel Sheet Material

Wanzhi Group produces ZAM steel sheet material in accordance with ISO 17925, EN 10346:2020 and other certified standards, ZAM sheets coating contains zinc (Zn: 55%~60%), aluminum (Al: 4-15%) and magnesium (Mg: 1-3%) and other metal elements, which play the role of preventing oxidation and corrosion, high temperature resistance and oxidation resistance, self-repairing, etc. in the process of application. It prevents oxidation and corrosion, high temperature resistance and oxidation resistance, and self-repairing.

Classification

- Low-aluminum type (Al:4-6%): automotive panels (good weldability)

- Medium-aluminum type (Al:6-11%): architectural roofing (balanced corrosion resistance/processing)

- High-aluminum type (Al:11-15%): photovoltaic mounts (extreme weathering)

Processing and Manufacturing

- Stamping: Bending radius down to 0.5t, deep-drawing limit LDR up to 2.3

- Welding: Resistance spot welding, laser welding, MIG welding

- Surface Finishing: Patterned surface with zinc crystals, Smooth surface, etc.

- Processing: Zinc-Aluminum-Magnesium strips, Zinc-Aluminum-Magnesium flat plates, profiled plates, etc.

- Further processing: Painting.

Physical properties

| Characteristic | Zinc-Aluminum-Magnesium Steel | Galvanized Steel (GI) | Stainless Steel (304) |

| Density (g/cm³) | 7.2 | 7.14 | 7.93 |

| Coefficient of Thermal Expansion (x10⁻⁶/K) | 13.5 | 12.0 | 17.3 |

| Thermal Conductivity (W/m·K) | 60 | 50 | 16 |

| Resistivity (μΩ·cm) | 15 | 6 | 72 |

Mechanical Property

| Characteristic | Zinc-Aluminum-Magnesium Steel | Galvanized Steel (GI) | Stainless Steel (304) |

| Yield Strength (MPa) | 350±30 | 350 | 205 |

| Tensile Strength (MPa) | 420±40 | 420 | 515 |

| Elongation (A80mm, %) | 22 | 18 | 40 |

| Hardness (HV) | 180 | 150 | 200 |

| Fatigue Limit (MPa) | 260 | 190 | 240 |

ZAM Steel Sheet for Sale

Wanzhi Group is selling coated metal sheets made from a variety of metal coatings including zinc coated, aluminum zinc coated, zinc aluminum magnesium coated, tin coated, and more. In addition, we offer OEM OEM service for steel, which can be customized according to your requirements.

Specification

| Parameter | Standard Range | Customization Ability | Tolerance Control |

| Substrate Thickness | 0.3mm – 3.0mm | Ultra-thin 0.15mm/Thickness up to 6mm | ±0.03mm (<1mm) |

| Sheet Width | 650mm – 1250mm | Narrowest 600mm/Widest 2000mm | ±1mm/Full Length |

| Coating Weight | ZAM60-ZAM180 (g/m²) | ZAM20-ZAM300 | ±10% |

| Coil Weight | ≥5tons | ≥10tons | ±0.5% |

Prices

ZAM sheet is influenced by a number of factors, such as coating structure, coating thickness, substrate material grade, surface treatment, etc. Regular sizes of ZAM steel are priced in the range of 700-900 USD/ton. Zinc-Aluminum-Magnesium (ZAM) steel has an initial price that is 25-45% higher than zinc-coated steel, but its self-repairing mechanism reduces the cost of maintenance by 90% and the long-term cost advantages of its 10 times corrosion-resistant + maintenance-free properties are more economically beneficial. Leave us a message with your project budget to get a steel solution and a quote for your project!

Plate Type

ZAM steel sheet can be classified into building-specific, structurally reinforced, functional composite and other steel plates with different surface structure and performance according to the engineering design of the appropriate scenario.

- Upright locking plate: wave height 65mm, hidden fastening, wind exposure 18kPa

- Corrugated plate: wave height 25-40mm Drainage slope ≥5%

- Flat locking plate: wave height 15mm Imitation of stone visual effect

- Trapezoidal ribbed plate: rib height 30-80mm, bearing capacity ≥5kN/m²

- Box girder plate: wall thickness 1.5-3.0mm, spanning up to 12m free of support

- Photovoltaic integration plate: integrated slot design, 60% faster installation speed Installation speed increased by 60%

- Acoustic noise reduction panel: perforation rate 15% + backing of sound-absorbing cotton, noise reduction coefficient NRC = 0.8

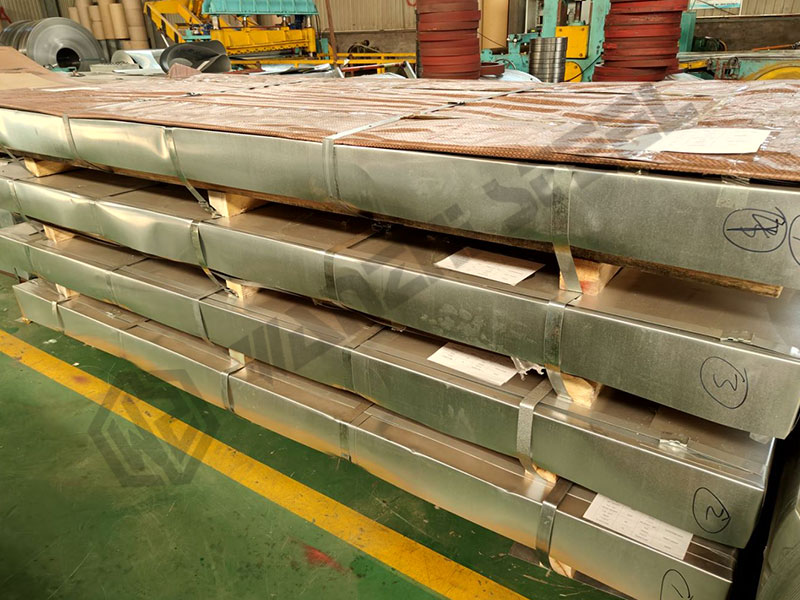

ZAM Steel Sheet Factory & Manufacturer

If you are looking for ISO9001, ISO14001 certified ZAM steel sheet factories, Wanzhi Group is your ideal partner. Our factories and products comply with international standards such as ISO, EN, GB, JIS, ASTM, etc., and we support third-party verifications such as SGC, BV and so on.

ZAM Steel Sheet Supplier

As a professional ZAM steel sheet coils supplier, we have supplied zinc-aluminum-magnesium coated steel materials for solar conduit projects and roof panel processing projects in Kazakhstan, Turkmenistan, Turkey, Vietnam, Turkey, France and 100 other countries and regions.

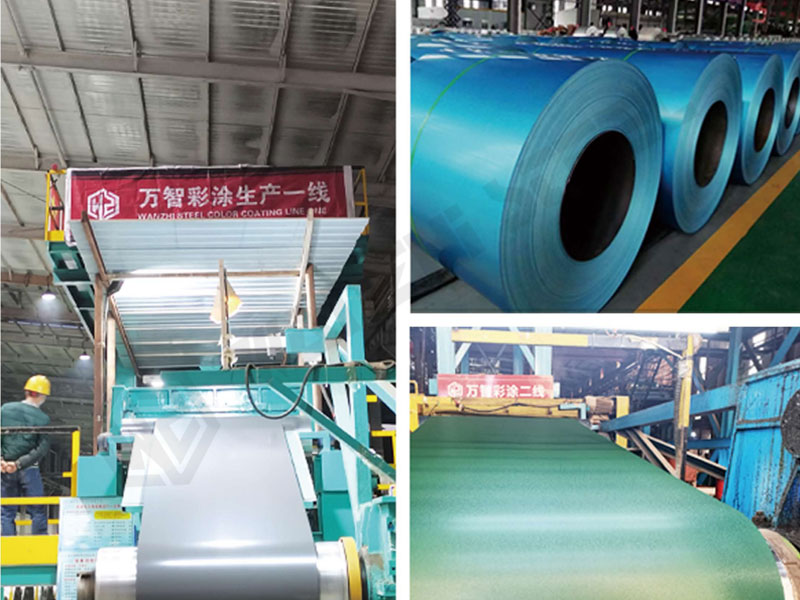

ZAM Steel Sheet Production Line

Our zinc-aluminum coated steel production line and profiled sheet coils are located in our factory in Binzhou City, Shandong Province, China, producing zinc-aluminum-magnesium coils, plates, strips, corrugated sheets and more, with an average production capacity of 10,000 tons per month, free samples are available.

ZAM Steel Sheet Advantageous Applications

ZAM Steel Sheet’s notch/shear edge protection, resistance to red rust, resistance to red rust, processability, excellent weldability, resistance to blackening, and excellent paintability make it a competitive or even upgraded alternative to galvanized (GI) and galvanized-aluminum-zinc coated (GL/Galvalume) steel sheets in industrial, construction, appliance, agricultural and new energy applications.

New Energy Sector

Photovoltaic support: 0.8mm high alumina ZAM150 plate instead of 1.5mm galvanized steel, weight reduction of 40%

Battery tray: 1.2mm ZAM120 instead of 304 stainless steel, cost reduction of 60%

Battery pack shell: 1.0mm ZAM120 stamping molding, resistant to corrosion of the electrolyte (cost reduction of 50% compared to 304 stainless steel)

Construction

Metal roofing 0.6mm ZAM180 + no coating 25 years (coastal environment), salt spray >3000h

Assembled walls 0.5mm ZAM100 color coated sheet, modular installation efficiency increased by 50%, 30 years (maintenance-free)

Steel structure corrosion protection layer 2.0mm ZAM200 50 years (C5 corrosion)

Automotive lightweight

Inner door panel: 0.6mm ZAM80 can replace 0.7mm GI+ coating.

Chassis guard: 1.0mm ZAM150 can replace 1.5mm 409 stainless steel.

Home Appliances & Smart Manufacturing

Air Conditioner Outer Unit: 0.5mm ZAM80 fingerprint resistant plate with 10 years salt spray life.

Industrial Robot Shell: 1.5mm ZAM100 electrostatic spraying, wear-resistant class 1.

ZAM Steel Sheet for house/ industry, home appliance manufacturing, new energy, etc. With excellent corrosion resistance, excellent self-healing ability, good processability, it is the material of choice for projects pursuing high reliability, long life and low total cost of ownership.