Zinc aluminum-magnesium coated steel (ZAM Steel) has become ideal for extreme environments such as offshore engineering and chemical plants due to its self-repairing ability, ultra-high corrosion resistance, and environmental protection.Wanzhi Group offers customized ZAM steel coil and sheet solutions and further processing services for architectural and industrial applications.

What is Zinc aluminum-magnesium Coated Steel?

Zinc aluminum-magnesium coated steel is a metal material with a uniform zinc-aluminum-magnesium alloy layer on the surface of Q235, SPCC, DX51D (cold-formed steel), and other steel as a substrate by hot-dip plating process.

Structure

Zinc-aluminum-magnesium steel consists of a substrate (steel) and a plating layer (zinc-aluminum-magnesium alloy). Al-Mg alloy)

- Substrate: Cold-rolled or hot-rolled steel

- Plating: Zinc-aluminum-magnesium alloy

Composition of the substrate

| Element | Content (%) | Function |

|---|---|---|

| C | ≤ 0.12 | Ensures ductility and weldability |

| Mn | 0.20-0.60 | Improves strength and hardenability |

| Si | ≤ 0.05 | Deoxidizes, reduces inclusions |

| P/S | ≤ 0.025 | Controls contaminants, prevents brittleness |

Mechanical properties of the substrate

| Tensile Strength | Yield Strength | Elongation | Hardness |

|---|---|---|---|

| 270~550 MPa | 140~350 MPa | 20%~40% | 60~120 HV |

Composition of coatings

| Elemental | content (%) | Function |

|---|---|---|

| Zn | 90-94 | Sacrificial anodic protection, dominant corrosion reaction |

| Al | 4-11 | Formation of oxide film, high-temperature resistance, and barrier protection |

| Mg | 0.2-3 | Promote self-healing, generate an Alkaline protective film |

| Si | 0.1-0.5 | Inhibits the overgrowth of Fe-Al alloy layer |

Specifications

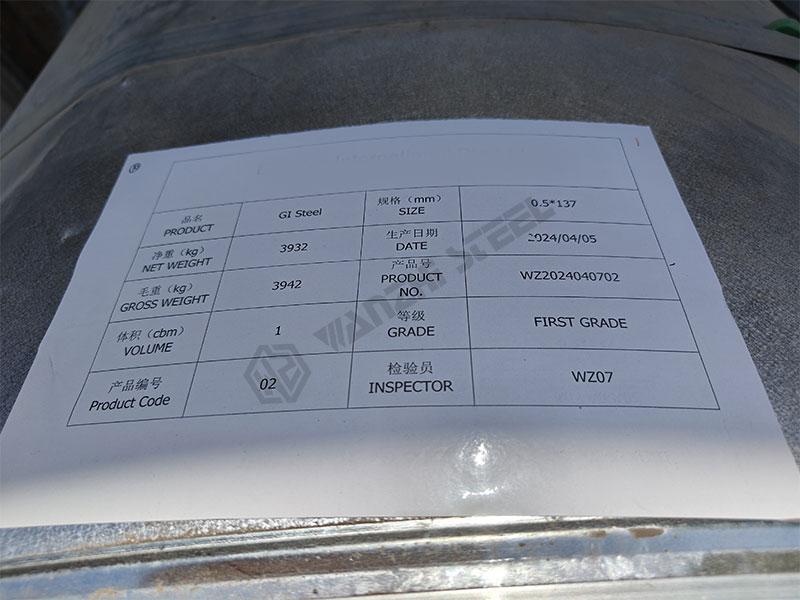

| ltem | Product Parameter |

|---|---|

| Type | ZAM Steel Coil |

| Based Metal | Cold Rolled Steel |

| Thickness | 0.5mm-4.0mm |

| Width | <1500mm |

| CoatingThickness | 80-275 g/㎡ |

| Standard | AISI, ASTM, DIN, GB, JIS, BS |

| SurfaceTreatment | Chromatedskinpassed/oiled/non-oiled /dry/Anti-finger printing |

| Applications | Mainlyused in construction,automobiles, homeappliances,hardware accessories, base metal, etc. |

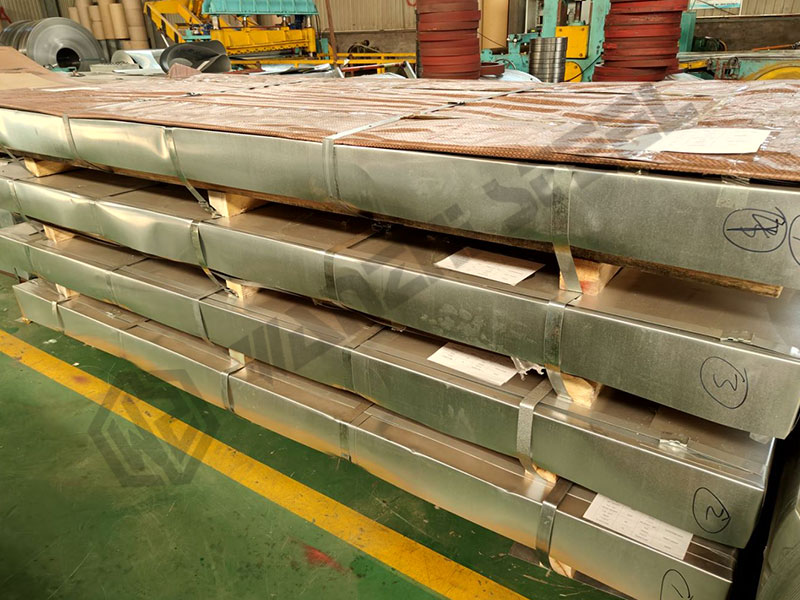

| Package | Standard exportpackage(waterproof paperinside and steel stripsoutside |

Why Choose Zinc aluminum-magnesium Coated Steel?

Zinc aluminum-magnesium coated steel combines the characteristics of steel, zinc, aluminum, and magnesium with excellent corrosion resistance, oxidation resistance, machinability, and abrasion resistance. It can be used as an alternative to stainless steel, prepainted steel, galvanized steel, and zinc-aluminum-plated steel in many applications.

In what Areas can Zinc-aluminum-magnesium be Used?

ZAM coil and sheet Widely used in building roofs, walls, window frames, metal façades, car bodies, chassis, motor housings, brackets, agricultural storage facilities, solar racks, parapet façades, cable bridges, noise barriers, and other applications, with a corrosion resistance of more than 25 years,

- Construction Industry: Coastal building roofs/walls, steel bridges.

- Automotive: Chassis guards, inner door panels.

- Appliances & Energy: Solar racks, air conditioning units.

- Agriculture and Transportation: Greenhouse skeleton, highway soundproof screen.

Where to Purchase Zinc Aluminum-Magnesium Coated Steel?

Zinc aluminum-magnesium coated steel is a kind of special coated steel with excellent corrosion and oxidation resistance, The main producing countries are China, Japan, Korea, India, Europe, etc. In recent years, many Chinese iron and steel mills have started to engage in the production of high-performance alloy-coated steel, Wanzhi Group is one of them.

ZAM Materials Manufacturer – Wanzhi Group

We have been committed to the production and processing of coated steel, providing premium coated steel to customers all over the world, popular products include galvanized, aluminum zinc plated, color coated galvanized, color coated galvanized, etc. We have 7 coated steel production lines. We have 7 coated steel production lines, one of which is responsible for the production of GL, ZAM steel coil. Furthermore, we provide zinc-aluminum-magnesium that meets the international standards of ISO, ASTM, JIS for the construction, automotive, and home appliance industries, as well as slitting, cutting, bending, forming, and other further processing.

Certificates

Cases

How to Make Zinc aluminum-magnesium ZAM-coated Steel?

Zinc-aluminum-magnesium steel is a multistep process of coating a steel substrate with zinc, aluminum, and magnesium alloys, starting with the preparation of the steel sheet/coil, followed by hot-dip galvanizing of the aluminum-magnesium coated steel, and then cutting and shaping of the coated steel to finish the quality control.

- Substrate pre-treatment: degreasing → pickling → auxiliary plating agent (zinc ammonium chloride) → drying.

- Hot-dip plating: immersed in 430-450°C ZAM alloy bath (Zn-Al-Mg-Si).

- Air Knife Control: Precise regulation of plating thickness (60-200g/m² on both sides).

- Cooling and post-treatment: water cooling → chrome-free passivation → oiling or laminating.

Which is Better ZAM, GI, GL?

| Indicators | GI (Galvanized) | GL (Aluminum-Zinc Plated) | ZAM (Zinc-Aluminum-Magnesium) |

|---|---|---|---|

| Salt Spray Resistance (hrs) | 200-400 (Z120) | 600-1500 (AZ150) | 1500-3000 (ZM150) |

| Cutting Corrosion Resistance | Poor (susceptible to red rust) | Medium (Aluminum Retarded Corrosion) | Superior (Self-healing) |

| Process Hardness (HV) | 70-150 | 200-300 | 250-400 |

| Cost | Low | Medium | High |

How to Buy our Zinc-Aluminum-Magnesium Coil Sheet?

We are very happy to provide you with free quotes and customized solutions. Contact us via WhatsApp, Email, or website, tell us the product specification or application you need, and we will provide you with the most competitive price for Zinc aluminum-magnesium coated steel.

Zinc Aluminum-Magnesium Coated Steel FAQ

High humidity, salt or industrial pollution

ZM100 (100 g/m² on both sides)

ZM150 (150 g/m² on both sides) or higher

ISO 14788: International Test Method for ZAM Sheets.

JIS G3323: Japanese Standard for ZAM Sheets.

ASTM A1046: American Standard Specification for ZAM Sheets