Customer Requirements

The client, with limited familiarity with aluminum-magnesium-manganese materials, contacted us via our roofing panels webpage. She expressed her need for a solution combining exceptional corrosion resistance and thermal insulation properties, seeking our professional material recommendation. Our business manager recommended black aluminum-magnesium-manganese plate based on the project location and application requirements.

Advantages of Aluminum-Magnesium-Manganese Roofing Panels

Compared to common color-coated steel sheets (PPGI/PPGL) on the market, aluminum-magnesium-manganese alloy roofing panels offer superior advantages in corrosion resistance, thermal conductivity and insulation, high strength combined with lightweight properties, formability, and aesthetic appeal. They are the preferred roofing material for buildings demanding high durability and energy efficiency.

| Product | Corrosion Resistance Performance | Thermal Insulation Performance | Suitable Scenarios |

| Aluminum-Magnesium-Manganese Roof Panel | Excellent. Aluminum-magnesium-manganese has anti-corrosion properties and can adapt to harsh environments such as humid and coastal areas. | Outstanding. The thermal conductivity coefficient of aluminum-magnesium-manganese alloy is reasonable. When combined with a dedicated thermal insulation layer, it can achieve efficient thermal insulation and reduce building energy consumption. | Lightweight and high-strength, suitable for large-span roof designs. |

| PPGI Roof (Color-Coated Galvanized Sheet) | Average. The corrosion-resistant lifespan is determined by the coating material and thickness. | Average. The thermal insulation performance also depends on the coating. | Low cost, suitable for ordinary buildings with general performance requirements. |

| PPGL Roof (Color-Coated Galvalume Sheet) | Good. The coating is similar to that of PPGI, but the galvalume substrate provides additional protection. | Average. Similar to PPGI roof panels, the thermal insulation performance requires additional safeguards. | Balances cost and a certain level of corrosion resistance, suitable for industrial or civil buildings with moderate requirements. |

| PPAL Roof (Color-Coated Aluminum Sheet) | Good. Aluminum sheets have a certain degree of corrosion resistance. | Good. The thermal conductivity of aluminum sheets is better than that of steel. | Lightweight and easy to process, suitable for projects that have weight requirements but do not have high demands on core performance. |

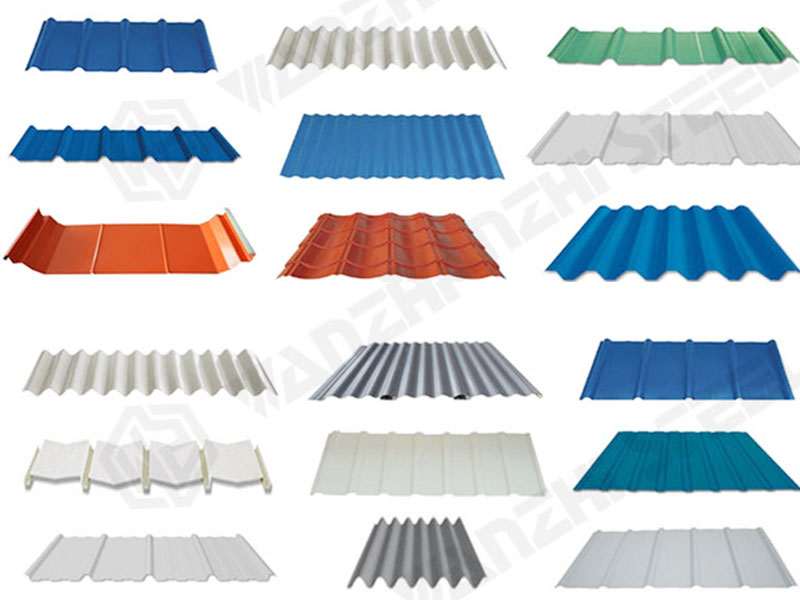

Wanzhi Group Roofing Panels

As a professional manufacturer of metal building materials, Wanzhi Group not only provides top-performing aluminum-magnesium-manganese roofing panels, but our team also delivers comprehensive services—from material selection and technical consultation to production and supply—tailored to each project’s climate conditions, architectural function, design style, and budget.

Pre-painted Galvanized Steel Roofing Panels: An economical and practical choice offering solid basic corrosion resistance and decorative properties.

Pre-painted Galvalume Steel Roofing Panels: Superior corrosion and heat resistance compared to standard galvanized panels, delivering high cost-effectiveness.

Color-coated aluminum roofing panels: Lightweight, corrosion-resistant, and flexible in design.

Aluminum-magnesium-manganese alloy roofing panels (customer-selected): Premium flagship products engineered for projects demanding ultimate longevity, performance, and energy efficiency.