Before buying PPGI (prepainted galvanized steel), it is best to understand the composition structure, price influencing factors, application requirements, acceptance criteria and other information of PPGI so that we can obtain a high-quality, cost-effective and competitively priced PPGI steel coil or sheet.

The Why & What

When buying PPGI, it’s crucial to match the steel material to the specific application. PPGI consists of a variety of structures, including cold-rolled steel, metal plating, and organic coatings, any combination of which can achieve different functions. A clear understanding of the requirements helps select the most appropriate material, thereby reducing costs and improving material utilization.

End Use

PPGI steel is a popular metal material for anti-rust coatings in the construction and industrial sectors. Its excellent corrosion resistance, weather resistance, decorative properties, formability, and durability play a vital role in various fields, including architecture, decoration, home appliances, automotive, energy, and advertising.

- Construction (Roofing/Cladding): Applications prioritize weather resistance, corrosion resistance, color durability, and aesthetics. Specific coating structures, thicker zinc coatings, and good rigidity may be required.

- Home Appliances: Applications prioritize surface quality (Class A finish), chemical resistance (such as detergents), scratch resistance, and formability. Substrate flatness and coating uniformity are extremely demanding.

- Furniture & Interior: Emphasizes aesthetics, diverse textures (such as wood and stone grain), environmental friendliness, and tactile feel.

- Automotive: Emphasizes lightweighting and corrosion resistance, with high requirements for substrate elongation and uniformity.

- Energy: Emphasizes durability, weather resistance, environmental adaptability, and reliability. The substrate can be selected based on load-bearing requirements.

- Public Facilities & Infrastructure: Emphasizes long-term durability, aesthetically pleasing design, ease of cleaning, and competitive long-term costs.

Processing Methods

PPGI steel’s processing performance is determined by the substrate. The substrate material can be selected based on various processing methods, including shearing, laminating, stamping, deep drawing, and bending.

- Commercial Quality: Suitable for simple bending, roll forming, and shearing.

- Forming Quality: Suitable for shallow drawing, tight bending, and complex roll forming.

- Deep Drawing Quality: Designed for processes such as deep drawing, severe stretching, and flanging.

Cost and Budget

PPGI coil prices range from $600-900 USD per ton. This price can vary depending on factors such as substrate material registration, galvanizing thickness, PPGI specifications, paint type, surface treatment, finish, additional processing, and order quantity. However, the higher production efficiency, lower scrap rates, longer service life, and reduced after-sales maintenance costs brought by high-quality PPGI sheet far outweigh the low price.

- Substrate Cost: Hot-Rolled Coil (HRC), Cold-Rolled

- Galvanizing Cost: Coating thickness, galvanizing process (hot-dip galvanizing/electroplating)

- Coating Cost: Paint, coating, and additional processing

The How & What to Look For Premium PPGI

Next, follow Wanzhi Gorup for a comprehensive understanding of PPGI steel from its three core components: substrate, plating, and coating.

Substrate

Material Grades

- DX51D/CS Type B/CR1, CR2/SGCC: Commercial grade, suitable for general processing and construction. Most commonly used.

- DX52D/CS Type A/CR3, CR4 SGCD1, SGCD2: Mechanical bite grade, suitable for light forming.

- DX53D/DDS/CR280DD, CR300DD /SGCD3, SGCD4: Deep drawing grade, suitable for drawing and deep forming (such as appliance panels).

- DX54D/EDDS/CR340DD, CR380DD/SGCD5 and above: Extra deep drawing grade, used for complex forming.

- HX180YD, HX220YD/SS Grade 33, 37/CR340LA, CR380LA/SGH340, SGH400: High-strength low-alloy steel (HSLA), used for lightweight structural components.

Selection Recommendation: Choose the lowest-cost grade while meeting performance requirements.

Substrate Thickness and Tolerance

Thickness is an absolute key factor in cost. PPGI thickness typically ranges from 0.12mm to 1.5mm. During the procurement process, ask your supplier to specify the tolerance range. Chinese, European, and American standards have different tolerances, which can be agreed upon based on the contract.

Zinc Coating

Coating Weight

The thicker the coating, the stronger the corrosion resistance, but also the higher the weldability and price. Common coating thicknesses: Z40, Z60, Z80, Z100, Z120, Z150, Z180, and Z275 (unit: g/m², total on both sides).

- Z80: Suitable for indoor or general environments.

- Z120–Z150: Suitable for most outdoor structures and generally corrosive environments. Recommended standard configuration.

- Z180–Z275: Suitable for highly corrosive environments (such as coastal areas and industrial areas).

Surface Treatment

- None (N): Susceptible to oxidation, for painted steel.

- Passivation (C): Most commonly used, for white rust prevention.

- Oiling (O): Prevents rust during transportation and storage.

- Phosphating (P): Improves paint film adhesion, for painted steel.

- Anti-Fingerprint (AF): Prevents rust and improves touch feel.

Paint Coating

The thickness of the color coating is typically 10-40μm on the front and 5-20μm on the back. The coating structure, paint material, and surface texture can all be customized.

Coating System

- Two-Coat-One-Bake (2/1): Primer + Topcoat.

- Two-Coat-Two-Bake (2/2): Primer + Topcoat; the most common and cost-effective.

- One-Coat-One-Bake (1/1): Topcoat only, the lowest cost.

- Three-Coat-Three-Bake (3/3): Primer + Topcoat + Protective Film (such as Clearcoat).

Paint System

- Polyester (PE): The most cost-effective coating, the preferred choice for most architectural and general applications.

- Siliconized Polyester (SMP): Better weather resistance and durability than PE, but slightly more expensive than PE coatings. High Durable Polyester (HDP): Performance similar to PVDF, but at a lower cost, making it an excellent upgrade from PE.

- Polyvinylidene fluoride (PVDF, 70% or more fluorocarbon): Offers top-tier weather resistance, excellent gloss and color retention, and the highest price.

- Plastic Sol (PVC): Provides a very thick coating with excellent scratch and corrosion resistance, but offers average weather resistance.

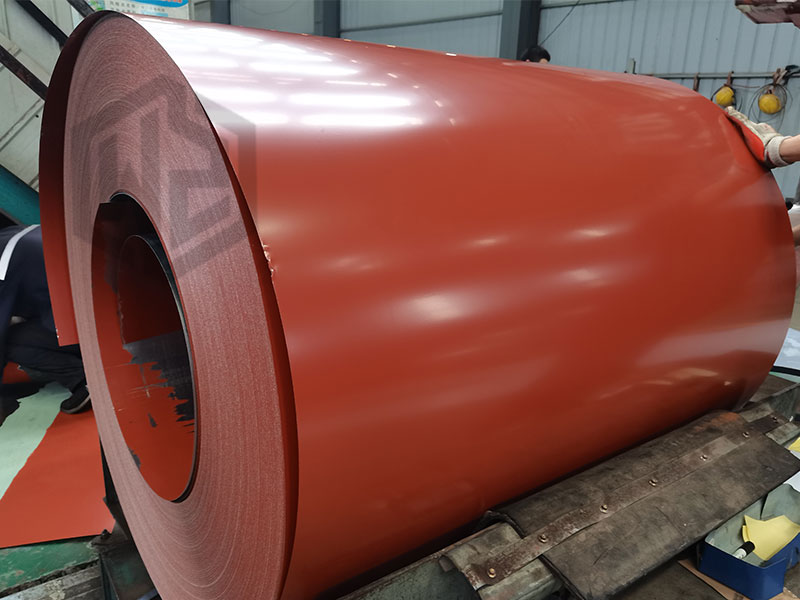

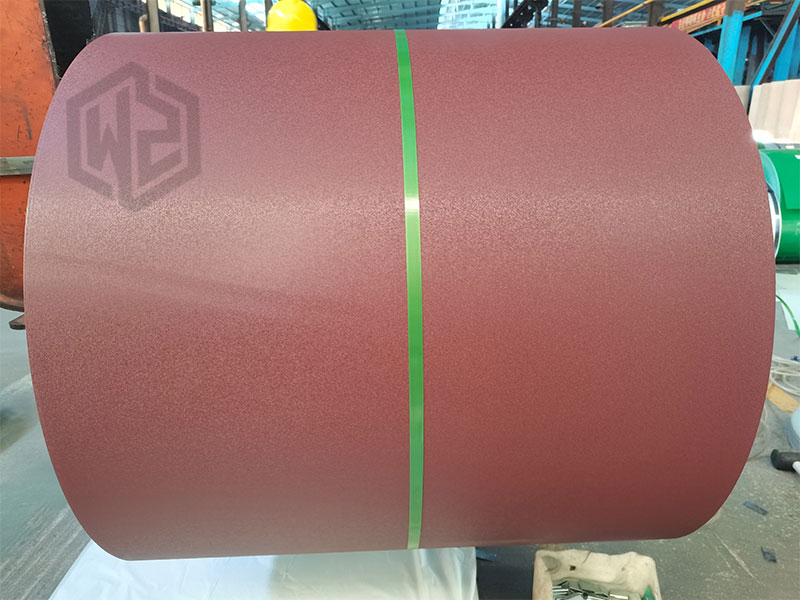

Surface Textures

- Glossy: Highly shiny and vibrant colors.

- Matt: Provides a premium feel, reduces glare, and hides minor scratches.

- Embossed: Highly conceals defects and offers a pleasant tactile feel.

- Pattern: Highly decorative.

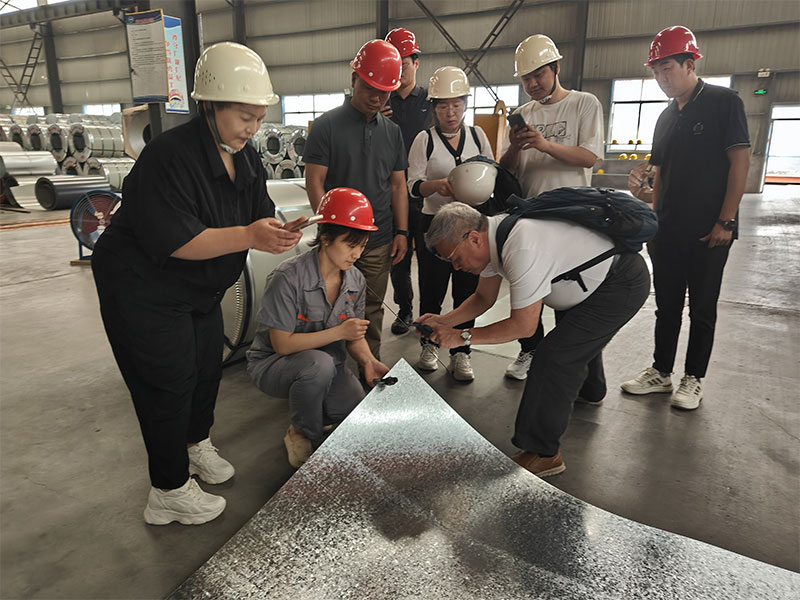

PPGI Inspection Checklist

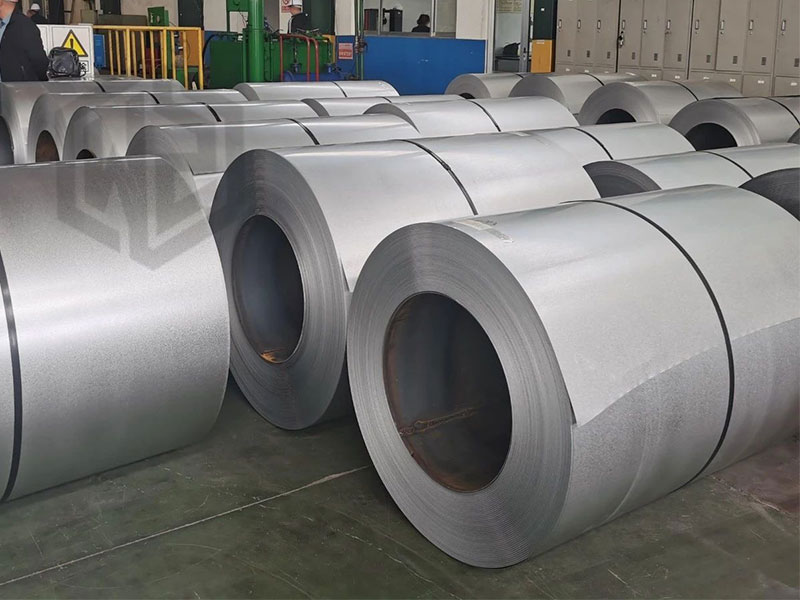

Quality control of PPGI steel coils determines the final product quality, yield rate, and production cost. Before cooperating, you can request a material certificate (MTC/COA) from the factory. After production, you can conduct on-site inspections or have a third-party inspection performed.

- Appearance: Inspect the PPGI steel surface for defects such as color difference, coating leaks, pinholes, scratches, roller marks, and paint bumps. Compare to a standard color chart under a standard light source.

- Dimensions: Thickness, width, and length are randomly measured for each batch of PPGI materials to ensure they are within tolerance.

- Film Thickness: The front and back coatings and the total film thickness are randomly measured using a magnetic or eddy current thickness gauge.

- Adhesion: A cross-cut test is performed to verify coating adhesion.

- T-Bend Test: The supplier provides a T-bend test report (e.g., 0T, 1T, 2T) to verify that the formability meets the standards.

PPGI Manufacturers vs. Traders

PPGI manufacturers and traders each have their own advantages during the transaction process. Sourcing from the PPGI factory offers consistent quality, technical support, and after-sales service. Choosing a PPGI trader offers a wider product range, a full range of specifications, smaller minimum order quantities, and better service.

Key Considerations:

- Factory Strength: Production lines, process control capabilities, testing equipment, and production capacity.

- R&D Capabilities: Whether customized colors, textures, and patterns can be provided.

- Quality System: Whether the company has ISO9001 certification. Whether it accepts third-party inspections such as SGS.

- Research Cases: Whether the company has experience serving the same industry.

- Additional Services: Whether the company has finishing capabilities such as shearing, forming, stamping, and laminating.

- Transportation: Whether the company has standardized export packaging standards and warehousing management (to prevent storage rust).

Wanzhi HOT PPGI Products – OEM ODM

Wanzhi Group has a PPGI factory (ISO9001, ISO14001D, and other certifications), galvanized and painted galvanized material production lines, and over a decade of export experience. We can provide professional solutions tailored to your application, processing method, and budget. We can also provide complete production and processing based on your substrate grade, thickness tolerance, coating weight, coating system, coating thickness, and color code. If you are looking for a reliable PPGI supplier, please contact us!