Solutions to Mechanical Damage on Galvanized Steel Surfaces

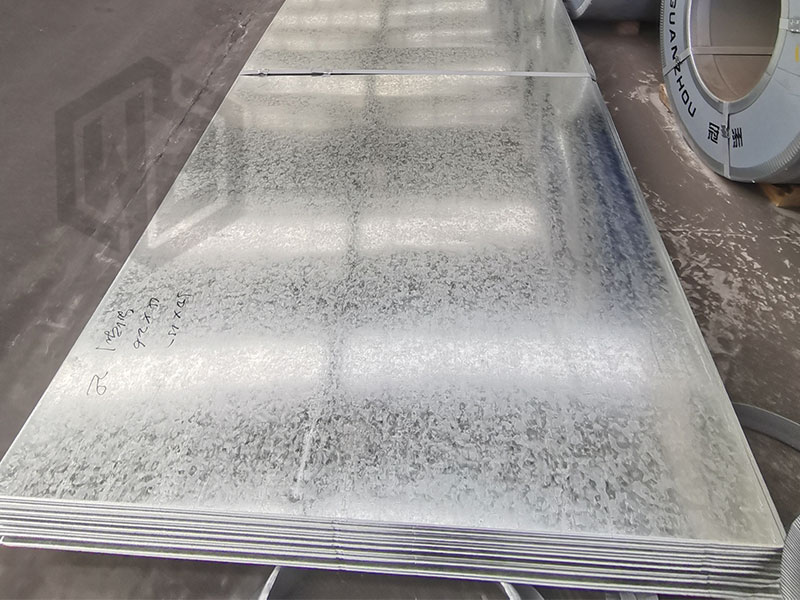

Galvanized steel is the most widely used anti-corrosion metal material. Due to its excellent corrosion resistance and high cost-effectiveness, it is widely used in construction, home appliances, industry, agriculture, and many other fields. The coating on the surface of galvanized steel is the core of its anti-corrosion protection. However, mechanical damage such as scratches, bumps, […]

Solutions to Mechanical Damage on Galvanized Steel Surfaces Read More »