What is Manufactured Home

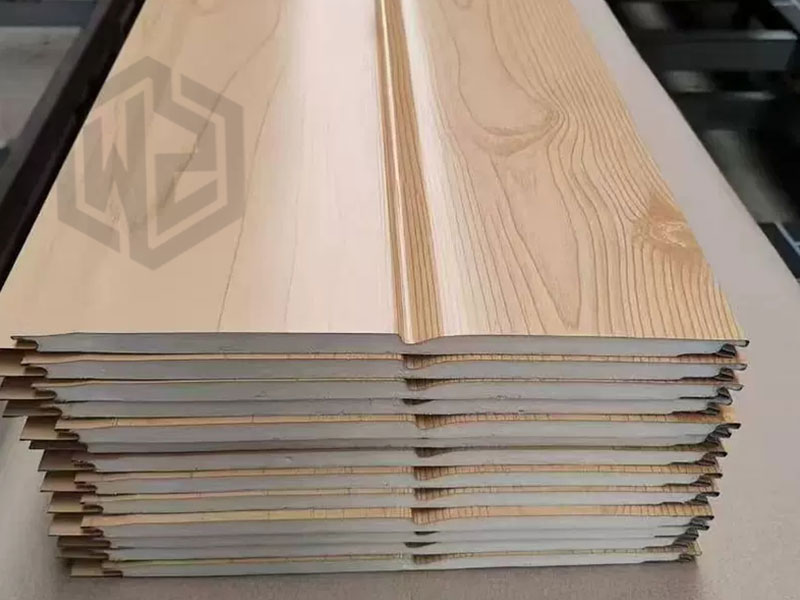

A manufactured home is a house that is produced and mostly assembled in a factory before being sold. It is a modern, economical, fast, controllable, flexible, and environmentally friendly prefabricated wooden/metal house that is widely used for personal residence, commercial operations, special needs, and other scenarios. Manufactured Home Definition A Manufactured Home (prefabricated steel house/mobile […]

What is Manufactured Home Read More »