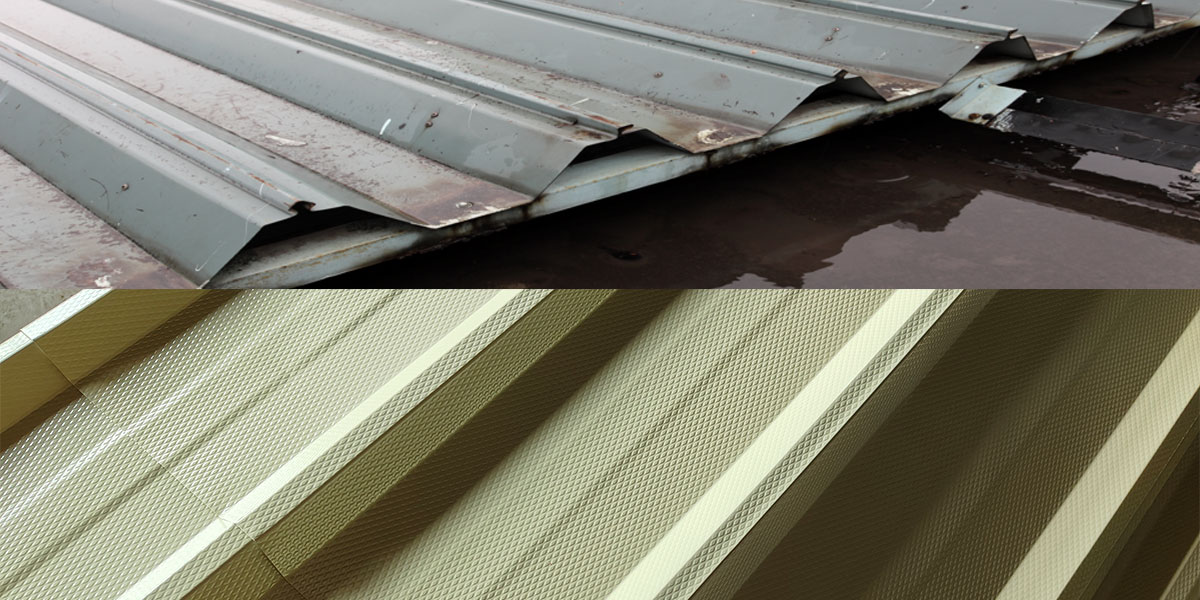

One common issue with outdoor PPGI material is surface rusting. Some coatings labeled as rust-resistant for 10-25 years develop rust spots within less than a year. What causes this phenomenon? And how can we resolve or prevent it?

Causes of Rust Formation on PPGI Steel Coatings

Production-Related Factors

- Uneven or insufficient zinc coating thickness: The zinc layer serves as the primary rust barrier for PPGI. Poor galvanizing processes can result in localized zinc deficiency, increasing susceptibility to electrochemical corrosion.

- Poor Coating Adhesion: Inadequate pretreatment (e.g., insufficient degreasing or passivation) compromises the bond between the paint film and substrate, causing premature peeling.

- Insufficient Paint Film Thickness: Coating thickness failing to meet design specifications, particularly at edges, corners, and welds, creates potential corrosion initiation points.

- Incomplete curing: Insufficient baking temperature or time prevents full coating curing, reducing weather resistance and corrosion protection.

Material Quality Defects

- Uneven or insufficient zinc coating: Inadequate zinc weight (e.g., Z90) or defects like missed coating areas cause premature loss of cathodic protection.

- Poor coating quality: Substandard paint formulations, excessively thin coatings, or inadequate curing result in insufficient barrier protection. Premature chalking and fading occur, ultimately compromising protective function.

Caused by Improper Use

- Coating damage (most common cause): Scratches or impacts during transportation, installation, or use compromise coating integrity, exposing the steel substrate to atmospheric elements.

- Excessive processing: During shearing, punching, or bending, coatings at cut edges or bends develop microcracks or peel off due to excessive deformation, losing their protective function.

- Highly corrosive environments: Exposure to harsh conditions like high humidity, high salinity, or acid rain accelerates coating degradation and metal corrosion.

- Improper cleaning/maintenance: Using strong acids, alkalis, or abrasive tools to scrub surfaces damages the protective coating layer.

- Surface contamination: Acidic/alkaline substances, metal particles, or salt deposits left on steel surfaces without timely removal.

Other Causes

- Design Defects: Structural areas prone to water accumulation or dust buildup are difficult to maintain and susceptible to rust formation.

- Poor Storage Conditions: Prolonged outdoor exposure to moisture and sunlight accelerates coating deterioration.

- Exceeding Material Tolerance Limits: Highly corrosive environments or prolonged exposure to moisture and standing water cause rapid degradation of paint coatings and galvanized layers.

PPGI Steel Paint Film Rust Solutions

Preventive Measures

- Strictly control raw materials and production: Select high-quality substrates, galvanized layer thickness, and coating thickness based on application environments.

- Enhance pretreatment processes: Improve degreasing, passivation, and other pretreatment procedures to boost coating adhesion.

- Optimize design and installation: Minimize structural dead zones whenever possible. Design PPGI panels slopes according to application requirements to prevent prolonged water and dust accumulation.

- Standardize Transportation and Storage: Use moisture-proof packaging, prevent impacts during transport, maintain dry and ventilated conditions. Immediately wipe and dry any surface water accumulation.

- Avoid Contact: Prevent direct contact with cement, mortar, chemicals, etc. If unavoidable, promptly rinse with clean water.

- Select Quality Suppliers: Choose factories with ISO quality management system certification. Require suppliers to provide complete Material Test Certificates (MTC).

Treating Rusted Surfaces

- Localized pitting or small rust spots: Sand rusted areas with sandpaper, clean thoroughly, then apply matching rust-proof paint for spot repair.

- Severe rusting: Completely remove rust layers from the PPGI steel surface, sand down to the metal substrate, and reapply rust prevention treatment and coating. For PPGI sheets unsuitable for spot repair, replacement is recommended.

PPGI Rust Repair Steps

Step 1: Rust Removal. Thoroughly sand rusted areas with sandpaper or small power tools until a metallic sheen is exposed.

Step 2: Cleaning. Wipe the area with a specialized cleaner (e.g., diluted phosphoric acid solution) to neutralize residual rust, then rinse with clean water and allow to dry completely.

Step 3: Repair. First apply a zinc-rich primer (providing cathodic protection). Once dry, spray a topcoat matching the original panel color. It is best to use the manufacturer’s original repair paint.

Premium PPGI Steel

To completely resolve corrosion issues, we recommend using PPGI materials matched to the application environment.

- Use PPGL steel with an aluminum-zinc coated substrate for enhanced fundamental rust resistance.

- Select coatings like PVDF or SMP for superior weather resistance and corrosion protection.

- Customize PPGI coatings for highly corrosive environments (e.g., coastal areas, industrial zones) and cleanroom/sterile environments.

Wanzhi Group – PPGI Products

Rusting of the paint film on PPGI steel within its service life is primarily caused by production and storage conditions. Selecting appropriate materials and suppliers, combined with proper usage and maintenance, can effectively prevent premature corrosion. However, if corrosion is already severe, it is recommended to replace the material as soon as possible.