DX51D+Z180 Galvanized steel coil sheet is the most cost-effective galvanized steel thickness for peri-industrial, low-salinity coastal environments, and is the king of cost-effective galvanized steel for moderately corrosive environments, better than Z120 and Z275. Wanzhi Group is a supplier of DX51D+Z galvanized steel from China, providing metal solutions with high load capacity, light weight and corrosion resistance to applications in construction, manufacturing and new energy.

DX51D+Z180

DX51D+Z180 is a hot-dip galvanized steel grade in accordance with GB /T 2518-2019 Continuous Hot-Dip Galvanized and Zinc Alloy Coated Steel Sheet and Strip Standard. DX51D indicates that the substrate of the steel sheet is cold rolled mild steel with good formability, and Z180 indicates that the thickness of the zinc layer is 180g/m2, which is a medium-high coating with excellent corrosion resistance.

DX51D Substrate Material

- Yield strength: 140-280 MPa

- Tensile strength: 270-420 MPa

- Elongation: ≥18% (A80mm)

- Hardness: 50-70 HRB

Z180 coating

- Thickness of coating: ≈ 25 µm (single side)

- Salt spray life: 1500 h (red rust appears)

- Structure of coating: 80% pure zinc + 20% Fe-Zn alloy layer

Surface Quality

- Provide Smooth, Matt texture, zinc spangle surface and other surface effects.

- Support chrome-free passivation (environmental protection), fingerprint resistance (AF, anti-fouling) and self-lubricating coating (reduce mold wear).

Processability

High elongation (≥22%) and low hardness support stamping, bending, cutting and other processes, can be processed galvanized flat sheet, galvanized corrugated sheet, galvanized pipe, galvanized strip, galvanized profiles and other finished metal materials.

Comparison of Similar Grades

| Grade | Coating Type | Coating Weight (g/m²) | Mechanical Properties |

| DX51D+180 | Pure Zinc (Zn) | 180 (both sides) | Yield strength ≤280MPa |

| DX52D+180 | Pure Zinc (Zn) | 180 (both sides) | Yield strength ≤240MPa |

| DX53D+180 | Pure Zinc (Zn) | 180 (both sides) | Yield strength ≤200MPa |

| Galvalume | Aluminum-Zinc (55% Al) | 150 (both sides) | Yield strength ≥300MPa |

Comparison of different zinc coating of DX51D+

| Coating | Coating Weight (g/m²) | Salt Spray Life (h) | Applicable Environment (ISO 12944) |

| Z60 | 60 | 500 | C2 (Low corrosion) |

| Z120 | 120 | 1000 | C3 (Urban industrial) |

| Z180 | 180 | 1500 | C3+/C4 (Light corrosion) |

| Z275 | 275 | 3000 | C4-C5 (Heavy corrosion) |

Advantages of DX51D+Z180 Galvanized Steel

- Upgraded corrosion protection: Coating weight 180 g/m², salt spray resistance up to 1500 hours.

- Substrate deep-drawing properties: DX51D has good ductility, good machinability

- Economic advantages: DX51D+Z180 is suitable for a wide range of applications, and in C3 (urban-industrial) environments the price/performance ratio exceeds that of DX51D+Z275.

DX51D+Z180 Galvanized Steel Applications

- Building & Structures: bridges and highway facilities, warehouses and industrial plants, storage racking stile, building roofing and wall coverings, window and door frames, structural steel components, fences and mesh fences.

- Industrial Production: automotive door panels, appliance housings, electrical control cabinets, bodywork housings, chassis and doors, appliance housings, electrical components.

- New Energy: photovoltaic racks, cold chain logistics shelves, power towers and smart courier cabinet enclosures, smart express cabinet enclosures. Intelligent Express Cabinet Shell, Power Tower and Communication Tower, Cable Bridge and Protection Tube, Wind Turbine Tower

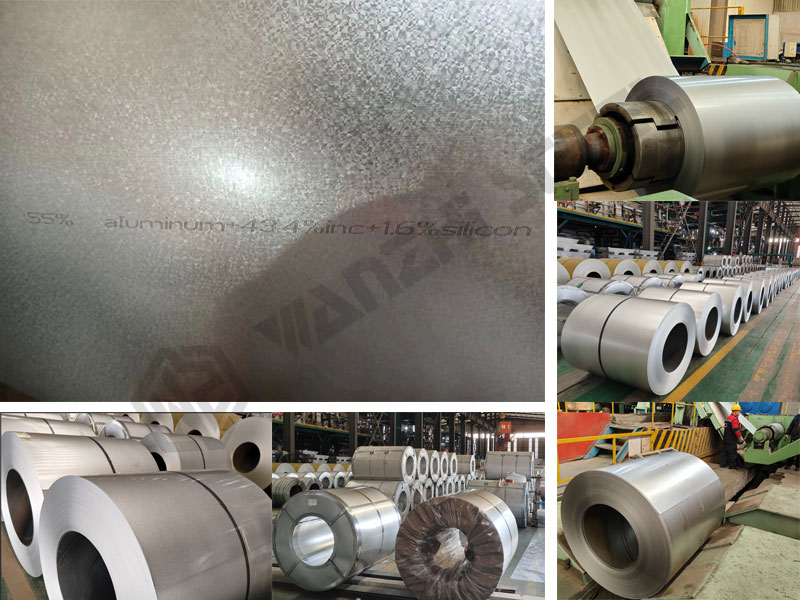

DX51D + Z180 Galvanized Steel Factory

DX51D + Z180 galvanized steel is the preferred galvanized steel material for medium corrosive environments and components requiring deep drawing, and is an economical alternative to Z275 galvanized steel in C3 corrosive environments with a high zinc coating. In addition to Z180,Z275, Wanzhi Group‘s DX51D+Z40/Z100/Z120/Z140/Z150 galvanized steel coil solutions are popular.

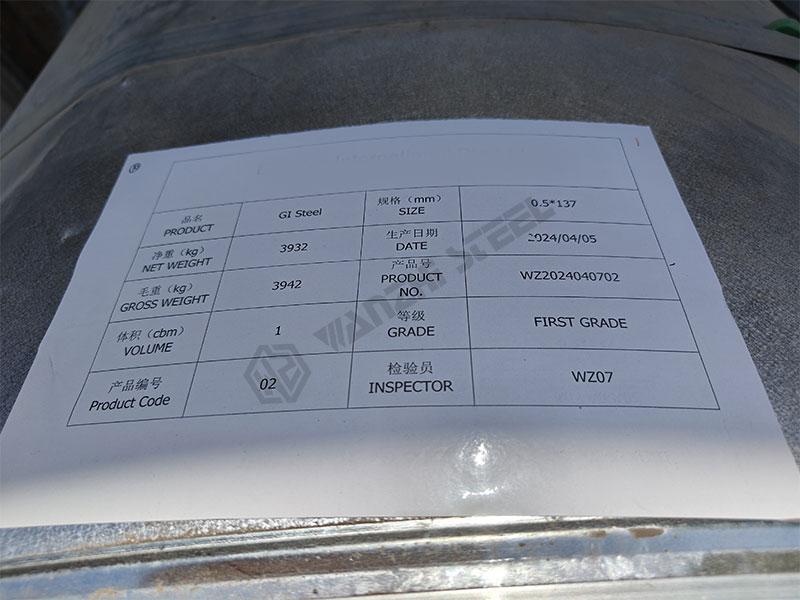

Factory

Wanzhi Steel Factory is ISO9001,ISO14001 certified and produces and sells a wide range of coated steel and alloy steel including GI, GL, ZAM, PPGI, PPGL, PPAL, stainless steel. We offer quality control, free samples, customization and many other services.

Customized

- Ultra-thin specification: 0.25-0.3mm

- Ultra-wide roll: 1600-2000mm

- Pre-punched plate: hole diameter Φ5-50mm

- Pre-painted: PE/SMP/PVDF/HDP/PU paint coating

- Surface: Smooth without zinc, regular zinc, small zinc, metallic texture, etc.

- Composite plating: Z180+Aluminum-Magnesium plating (heat resistance ↑ to 400℃) → Baking equipment shells

2 Containers Galvanized Steel Strip to Singapore

Project of PPGI Roofing en Libya

DX51D+Z180 is the ideal choice for structural and exterior parts in moderately corrosive environments due to its well-balanced corrosion resistance, processability and economy. Its wide range of application scenarios (construction, home appliances, industry) and mature process control (e.g. air knife plating accuracy ±3g/m²) make it occupy an important position in the civil industry. The selection of materials needs to take into account specific environments, costs and processing needs in order to optimize its performance.