AZ30-AZ150 Galvalume Steel refers to steel sheets with a 55% aluminum-zinc alloy coating weighing between 30 g/m² and 150 g/m² (total for both sides). This represents Wanzhi Group’s core product line in the field of high-performance corrosion-resistant steel. Offering exceptional corrosion resistance, superior heat tolerance, and high thermal reflectivity, it serves as the ultimate solution for humid, coastal, industrially polluted, and high-temperature environments.

AZ30-AZ150

” AZ” denotes an aluminum-zinc alloy coating, with the number indicating the total coating weight per square meter on both sides of the steel sheet. Thicker coatings offer superior corrosion resistance but also come at a higher price. The most common coating thicknesses range from 30 g/m² to 150 g/m². GL steel exceeding 150 g/m² requires custom manufacturing (minimum order quantity for custom orders is 50-100 tons). .

Applications

| Coating Grade | Application Scenarios |

| AZ30 – AZ60 | Enclosures (roofs/walls) of general industrial and commercial buildings, storage facilities in dry or inland areas, light-duty structural components. |

| AZ80 – AZ120 | Non-coastal buildings in coastal areas, industrial plants in high-humidity and rainy regions, public facilities with high service life requirements, agricultural buildings. |

| AZ150 | Harsh industrial areas, coastal and seaside buildings, port facilities with high salt spray, permanent structures with extreme anti-corrosion lifespan requirements. |

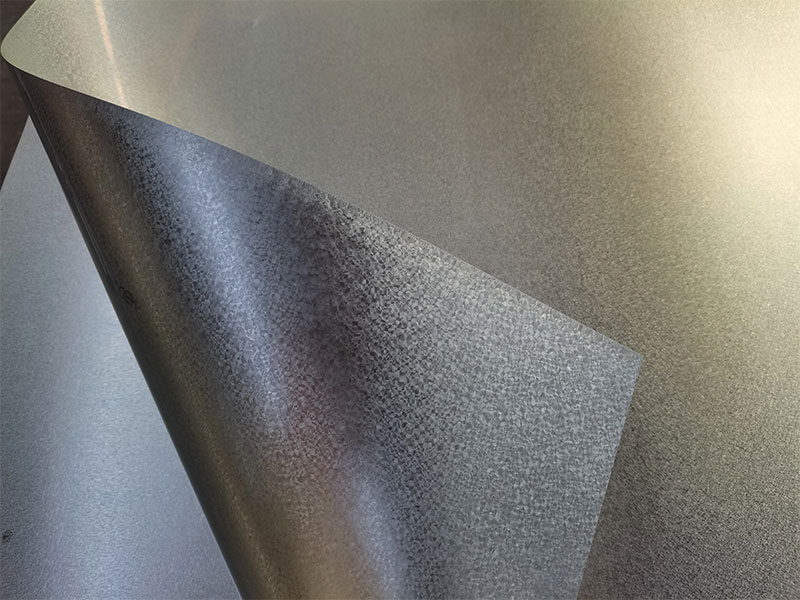

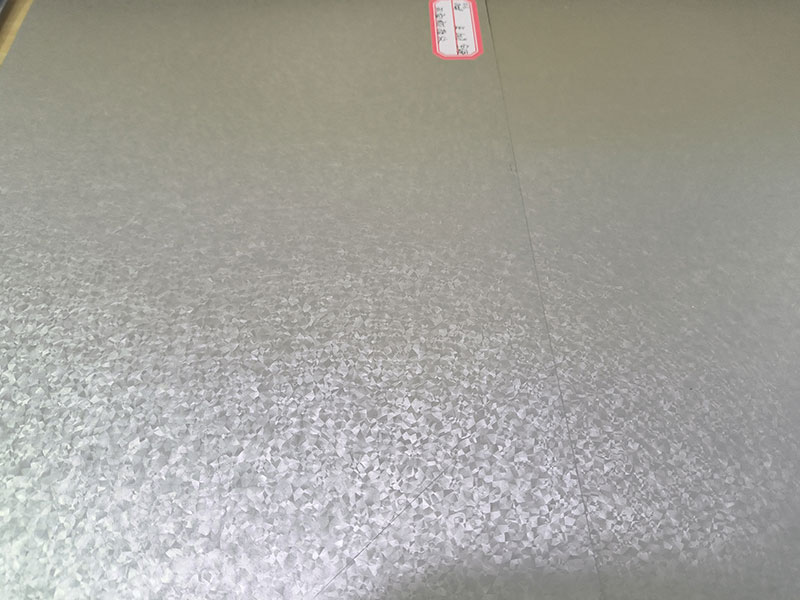

Surface Finish

- Smooth Surface: Features a uniformly smooth surface with a dense metallic sheen, serving as an ideal substrate for high-quality pre-painted steel (PPGL) and laminates.

- Standard Commercial Surface: Exhibits subtle solidification characteristics of the aluminum-zinc alloy, meeting the aesthetic and functional requirements of most architectural and industrial applications.

- Fingerprint-Resistant/Chromium-Free Passivated Surface: Specially treated to resist fingerprint contamination, environmentally friendly, and enhance subsequent adhesion. Suitable for high-end home appliances and electronics.

Core Features

- Exceptional Corrosion Resistance: Aluminum forms a dense oxide layer that blocks corrosion, while zinc provides electrochemical protection. Under equivalent coatings, its corrosion resistance lifespan is 2-6 times that of traditional galvanized steel (GI).

- Outstanding Heat Resistance & Thermal Reflectivity: Withstands sustained temperatures up to 315°C (635°F) and short-term exposure to 480°C (832°F). The bright silver surface reflects over 80% of solar energy, significantly reducing building energy consumption.

- Superior Cut Edge Protection: Aluminum in the coating migrates to cut edges, forming a protective oxide layer that significantly delays edge corrosion. Edge durability far exceeds that of galvanized steel.

- Excellent workability and cost-effectiveness: Maintains superior forming, bending, and joining properties. While initial costs are higher than GI, it offers better total lifecycle cost.

AZ30-AZ150 Galvalume Steel Full Product Range

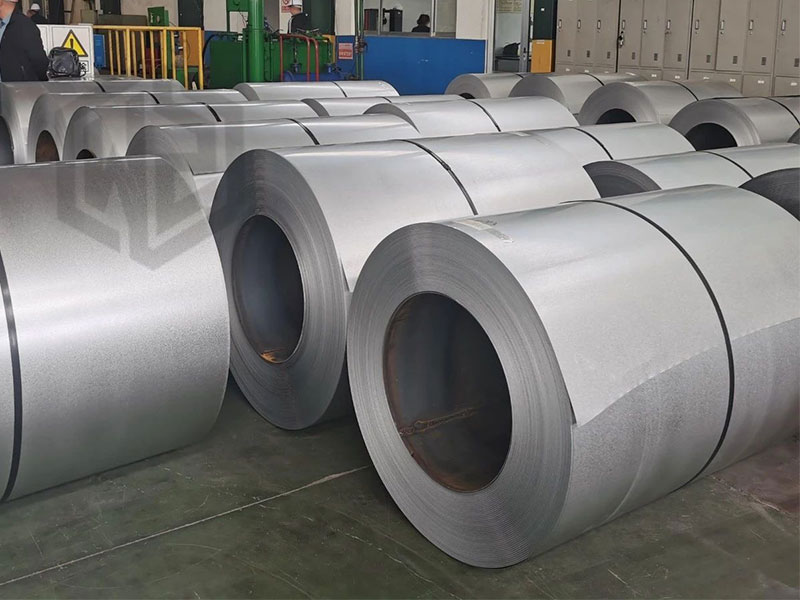

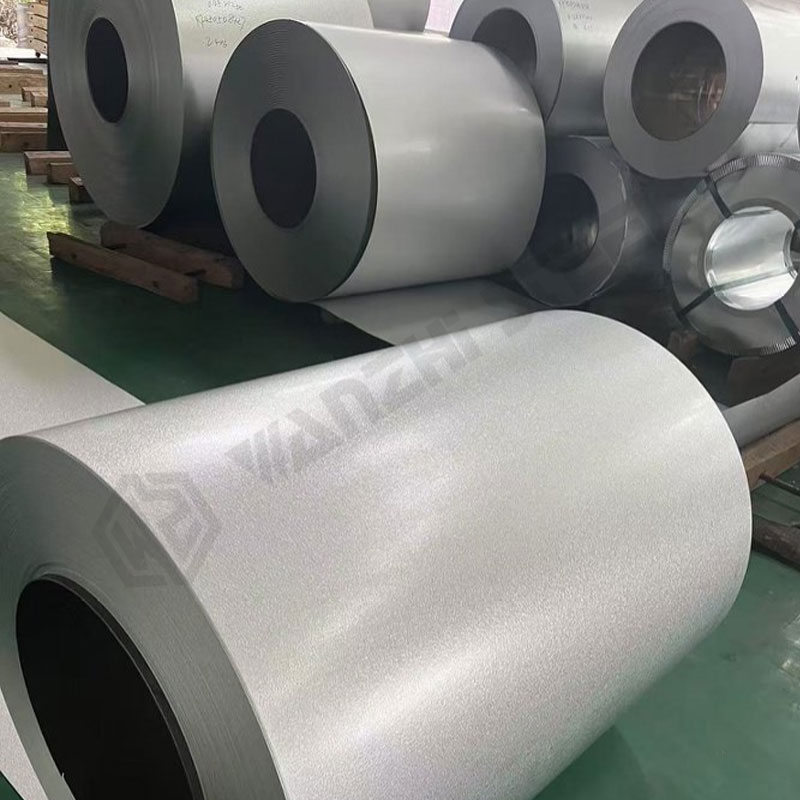

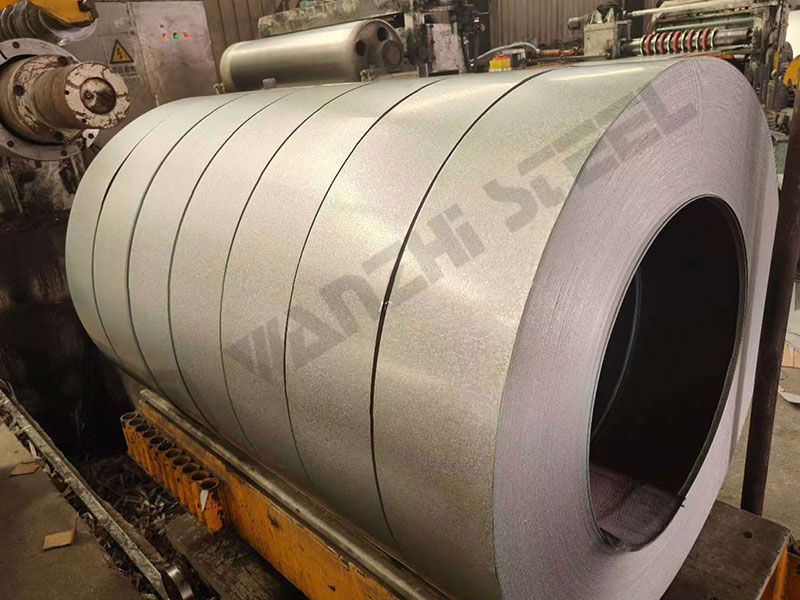

AZ30-AZ150 GL Coil (Galvalume Steel Coil)

The base coil produced by the hot-dip Galvalume production line serves as the source material for all subsequent deep processing.

Specifications: Thickness 0.15-3.0mm, Width 600-1250mm (customizable).

Applications: Supplied to large processing centers for leveling, slitting, and profiling, or as standard Galvalume material for trade distribution.

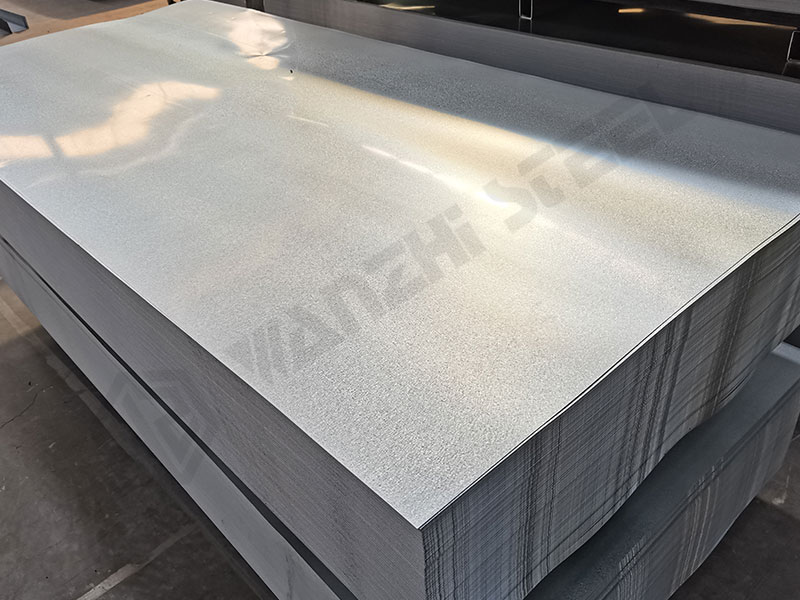

AZ30-AZ150 Galvanized Steel Sheets

Flat sheets produced by precision leveling and cut-to-length shearing of coils, featuring accurate dimensions and flat form.

Features: Customizable length with strictly controlled diagonal tolerances, suitable for direct processing or as base material for building wall panels.

Applications: Dry-hanging substrates for building exteriors, appliance enclosures, distribution cabinets, and construction projects requiring secondary on-site forming.

AZ30-AZ150 Galvalume Steel Strips (Aluminum-Zinc Coated Steel Strips)

Narrow strip products produced by high-precision slitting of wide coils.

Features: Width tolerance ±0.1mm, burr-free edges, uniform coating, and neatly wound coils.

Applications: Manufacturing cable trays with higher corrosion resistance requirements, specialized welded pipes, automotive exhaust pipe heat shields, and precision metal stamping parts.

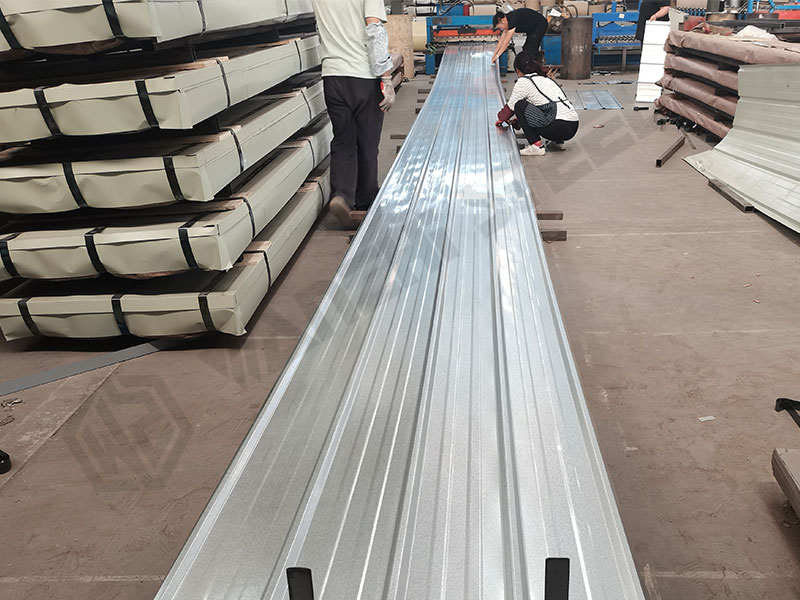

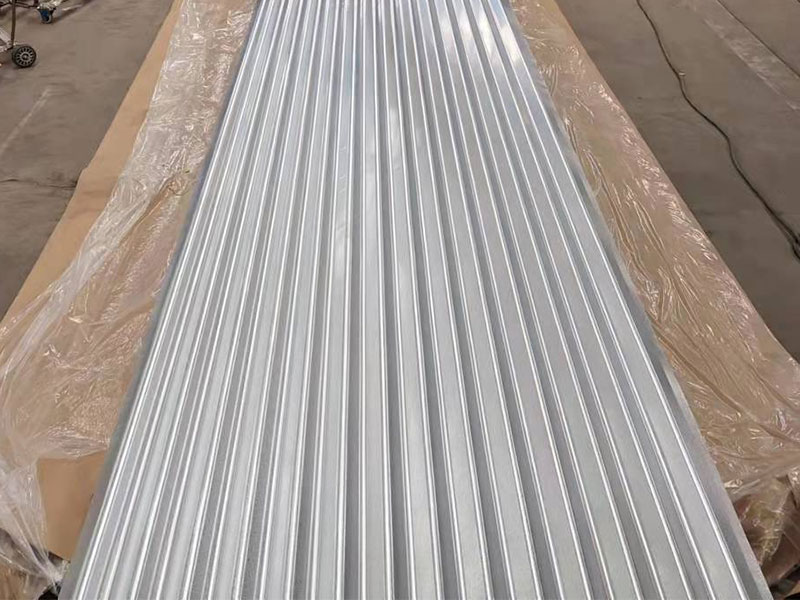

AZ30-AZ150 GL Panel

Building panels formed by roll forming aluminum-zinc coated coils.

- Products: Standing seam system panels, high-strength trapezoidal panels, corrugated panels, and aluminum-zinc coated sandwich panel facings.

- Core Characteristics: Roll forming significantly enhances panel bending strength and wind resistance. When combined with rock wool/polyurethane cores, it delivers corrosion resistance, thermal insulation, and soundproofing—suited for complex outdoor environments without additional protection.

- Applications: Premium industrial and commercial roofing/wall systems, large public building envelopes (airports, stations), cold chain logistics warehouses.

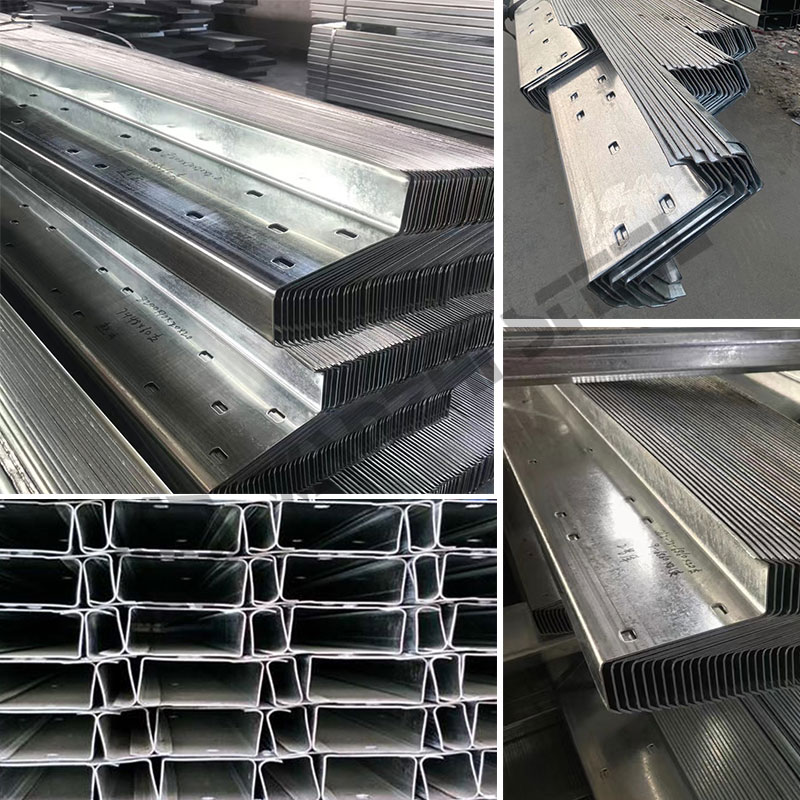

AZ30-AZ150 GL Structure

Cold-formed or assembled structural components manufactured from aluminum-zinc coated steel.

- Products: AZ-coated purlins (C/Z-shaped), lightweight studs, angle steel components, square/rectangular tube assemblies, equipment supports, warehouse shelving.

- Features: High dimensional accuracy, structurally robust, stable performance in corrosive environments.

- Applications: Steel structures for chemical plants, protective fencing, coastal building/facility components, high-standard agricultural greenhouse frameworks.

AZ30-AZ150 PPGL Steel

Premium composite panels featuring AZ30-AZ150 aluminum-zinc steel substrates coated with high-performance finishes (polyester, HDP, PVDF).

- Main Products: PPGL coil (color-coated aluminized zinc steel coil), PPGL sheet (color-coated aluminized zinc steel plate), PPGL panel (color-coated aluminized zinc profiled sheet), PPGL strip (color-coated aluminized zinc steel strip), etc.

- Features: “Premium substrate + premium coating” delivers exceptional corrosion resistance, coating weatherability, and decorative appeal, particularly suited for regions with intense UV exposure and high corrosion.

- Applications: Landmark building curtain walls, high-end residential exterior walls, premium roofing systems, specialized industrial building enclosures, coastal outdoor decorative components, and more.

Coil Packaging and Quality Assurance

Wanzhi Factory holds ISO9001, ISO14001, and ISO45001 certifications, ensuring full traceability from raw materials to finished products. We offer OEM/ODM services for AZ30-AZ150 galvalume steel, with finished goods packaged under stringent export standards to guarantee intact global delivery.

- Production Capacity: 600,000 tons annually

- Lead Time: 5-45 business days

- Customization: Base material, coating thickness, specifications, surface treatment, product form

- Packaging: Internal protection, reinforced labeling, structural fastening, palletization

Customer Feedback

Wanzhi Group‘s AZ30-AZ150 Galvalume Steel series has earned the trust of customers in over 50 countries and regions worldwide through its stable performance, precise coating control, and outstanding long-term cost-effectiveness. End-use applications span construction, industrial sectors, home appliances, and energy industries. Particularly in coastal construction projects and photovoltaic energy facilities, customers highly commend the product’s salt spray corrosion resistance and UV stability!

Whether you are an end-user seeking long-term corrosion protection solutions or a trader/processor requiring reliable, high-quality materials, Wanzhi Group’s full AZ30-AZ150 Galvalume steel product line and services precisely match your needs. Contact us today to receive complimentary samples, detailed technical documentation, and an optimized quotation tailored to your project!