Galvanized wire, a metal wire with excellent corrosion resistance, is one of the most basic yet indispensable materials in construction, agriculture, industrial manufacturing, and everyday hardware. It is widely used in construction binding, agricultural greenhouses, and industrial protection. Galvanized wire can be divided into galvanized hard wire and galvanized soft wire according to its material and manufacturing process. Today, let’s learn about these two types of corrosion-resistant wire with Wanzhi Group, from specifications, applications, characteristics to selection!

Common Specifications of Galvanized Wire

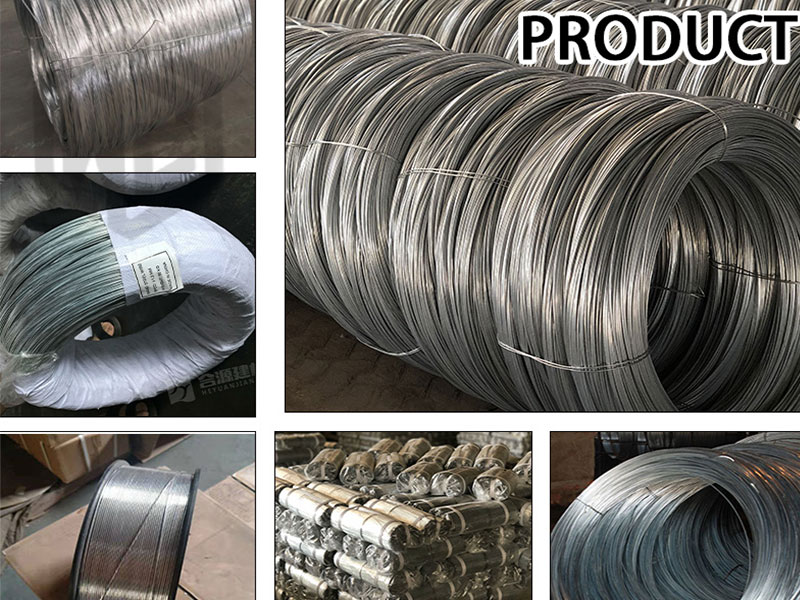

Whether it’s hard or flexible wire, the basic specifications of galvanized wire determine its applicable range; the diameter determines its application scenarios; and the coating thickness determines its corrosion resistance lifespan. Currently, Wanzhi Group offers various specifications, including ultra-fine wire, common specifications, coarse specifications, and extra-coarse wire. Multiple packaging methods are available, such as coils, straight bars, I-beams, and drums, to suit different storage and usage needs.

Diameter Range

| Wire Gauge (SWG) | Diameter (mm) |

| 8# | 4.00 mm |

| 10# | 3.25 mm |

| 12# | 2.64 mm |

| 14# | 2.00 mm |

| 16# | 1.63 mm |

| 18# | 1.22 mm |

| 20# | 0.89 mm |

Coating type

| Process | Zinc Layer Weight (g/m²) | Corrosion Resistance Performance |

| Hot-dip Galvanized Wire | Z60 – Z275 | Strong |

| Electro-galvanized Wire | Z10 – Z50 | Moderate |

Applications of Galvanized Wire

Galvanized wire can be used as a weaving, binding, and maintenance material.

Construction Sector

- Reinforcement Binding: Fixing beam and column reinforcement, formwork fixing

- Scaffolding Protection: Weaving protective netting, scaffolding connection

- External Wall Insulation: Fixing insulation boards

- Others: Temporary fixing, decorative binding, lightweight structures

Agriculture Sector

- Greenhouse Film Pressing: Fixing plastic film, greenhouse construction

- Orchard Trellising: Grape trellis, fruit tree support, fence posts

- Animal Husbandry Fencing: Weaving animal husbandry netting, temporary fencing

Industrial Sector

- Machinery: Making equipment protective netting, machine parts, screen weaving

- Handicraft Processing: Bending and forming, packaging and binding

- Cable Armoring: Wrapping the outer layer of cables

- Industrial Manufacturing: Electronic components, spring manufacturing

Daily Necessities

- Clothes Racks: Support wire

- Handicrafts: Storage baskets, woven frames, DIY projects

- Gardening Binding: Plant binding

What is Galvanized Hard Wire?

Galvanized hard wire refers to galvanized steel wire that has undergone cold drawing without annealing, maintaining high strength and hardness. It possesses excellent mechanical properties, but relatively low ductility. Popular grades: SWRH72A, SWRH82B (high carbon steel series).

Production Process

- High-quality wire rod → Pickling and rust removal → Cold drawing (key step) → Heat treatment (some products) → Galvanizing → Wire winding and packaging

Features

- High strength: Tensile strength ≥ 450MPa

- Low elongation: Elongation ≤ 5%

- Condition: Strong shape retention, not easily bent

- Appearance: Smooth surface, uniform diameter

- Precise dimensions: Small diameter tolerance

Advantages

- Resistant to deformation, strong load-bearing capacity

- Wear-resistant, fatigue-resistant

- High construction efficiency

- High cost-effectiveness

- Easy to shape

- Wind-resistant

What is Galvanized Flexible Wire?

Galvanized flexible wire refers to wire that has undergone cold drawing and annealing. It possesses good flexibility and ductility, but its strength is lower than that of galvanized hard wire. Typical grades include Q195 and Q235 low-carbon steel annealed series.

Production Process

- Wire rod raw material → Pickling → Cold drawing → Annealing → Galvanizing → Winding

Features

- Excellent flexibility: Tensile strength ≤350MPa

- High elongation: Elongation ≥15%

- Ease of processing: Easy to bend

- Appearance: Soft and slightly rough surface

- Good binding properties: Strong knots, easy operation

Advantages

- Easy to process, malleable

- High adaptability, good fit

- Weavable

- Easy to bind

- Safe and reliable

- Widely applicable

How to Choose between Galvanized Hard and Flexible wire?

Choose hard wire for load-bearing, choose flexible wire for bending

- Galvanized hard wire provides high strength support and creep resistance, meeting the needs of applications requiring load-bearing/deformation resistance or long-term outdoor use. Galvanized annealed wire has low bending resistance, easy handling, and shape fit, meeting the needs of applications requiring bending/weaving and indoor manual operation.

Automated selection of hard wire, manual selection of flexiblewire.

- Hard wire offers superior dimensional stability, processing consistency, and stable wire feeding, reducing the likelihood of machine jamming.

- Flexible wire is gentler on hands, requires less effort, is easier to control, and can be repeatedly adjusted, saving time and labor during manual operation.

Hard wire is slightly more expensive, soft wire offers better value.

- Galvanized hard wire requires multiple drawing passes, resulting in higher processing costs and the use of specialized tools. Flexible wire has lower material and labor costs compared to hard wire.

Frequently Asked Questions

Q1: Can rigid wire be used instead of flexible wire?

- No, it cannot be arbitrarily substituted; it must be matched according to the specific needs of the application.

Q2: Is the strength of flexible wire sufficient?

- The strength of flexible wire is sufficient for most binding and securing applications.

Q3: Do galvanized rigid and flexible wires of the same diameter have the same corrosion resistance life?

- The corrosion resistance life of galvanized steel wire is determined by the thickness of the coating.

Q4: How to judge the quality of the galvanized layer?

- The surface should be uniform and bright, without any missed areas or peeling. The zinc layer should not peel off after a winding test.

Q5: Can rigid and flexible wires be welded?

- Rigid wire is difficult to weld; flexible wire is easier to weld.

Q6: What precautions should be taken when storing?

- Keep dry, avoid humid environments, and keep away from acidic and alkaline substances.

If you have any questions about the diameter, strength, coating type, or applications of galvanized wire, please leave a message to discuss with us.