What are Galvanized Steel and Stainless Steel Materials?

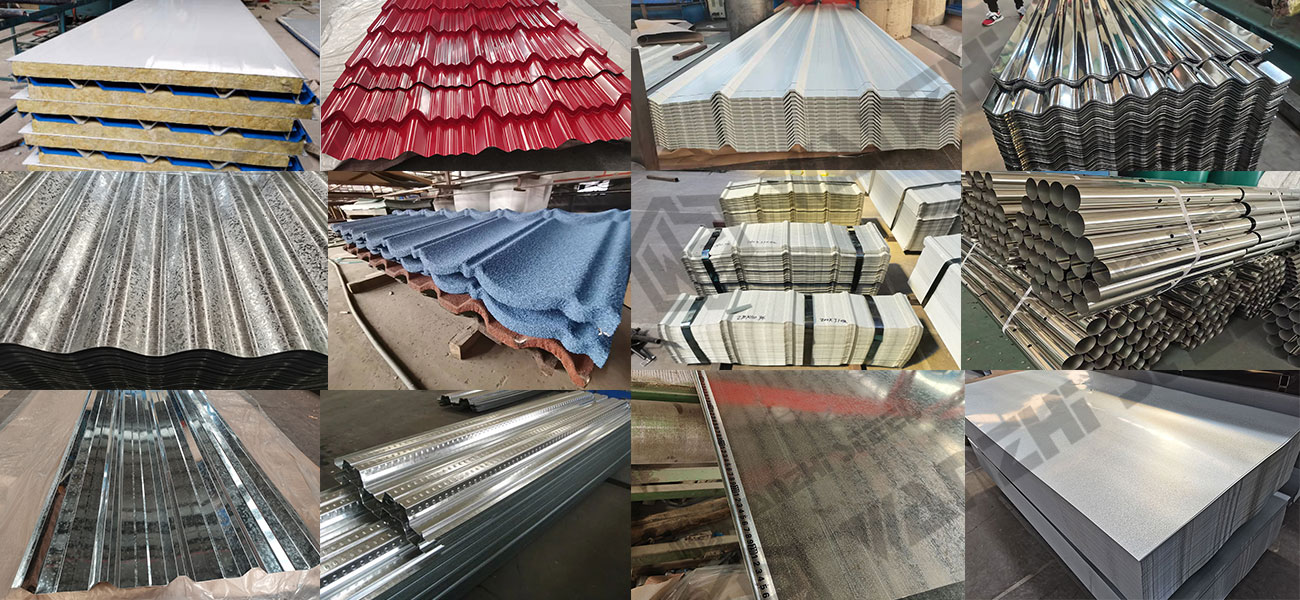

Galvanized steel is a coated steel, and stainless steel is an alloy steel. Both are high-quality materials for steel products in more industries, through cutting, slitting, punching, bending, forming and other deep processing can be made into steel plates, coils, strips, panels, steel structures, and so on.

Galvanized Steel Material

Galvanized steel is steel with a zinc coating on the surface, which is simple to process and whose corrosion resistance is determined by the thickness of the zinc layer on the surface. Similarly, galvanized steel can also be used as a substrate for roll-coating the surface with a special color coating to make pre-painted color-coated galvanized steel (PPGI steel).

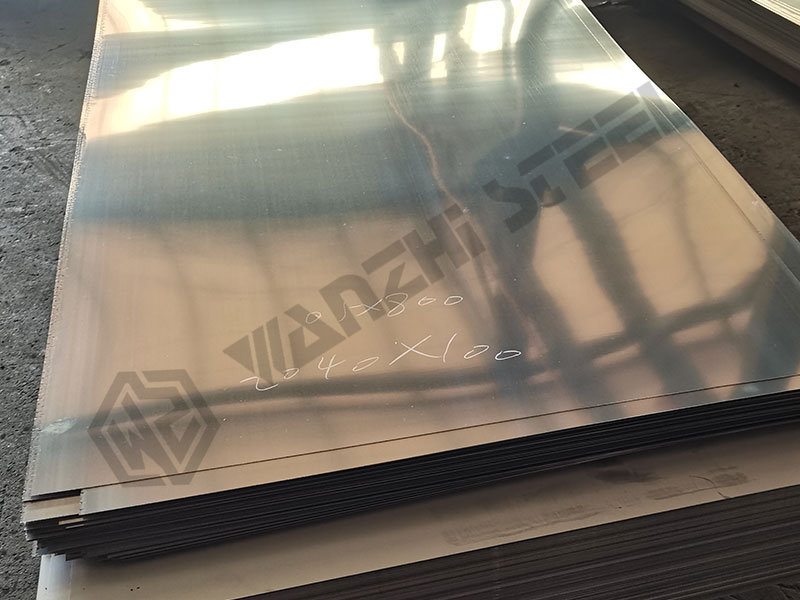

Stainless Steel Material

Stainless steel is composed of steel and chromium, nickel, and other alloying elements of alloy steel, corrosion resistance is determined by the chromium content (usually ≥ 10.5%). In the production process can also be added by adding nickel, molybdenum, and other elements to increase its performance, stainless steel variety, main types are austenitic stainless steel ferritic stainless steel, martensitic stainless steel, duplex stainless steel, and so on.

What are the Differences Between the Properties of Galvanized Steel and Stainless Steel?

Although galvanized steel and stainless steel are both metallic materials composed of the element iron, there are significant differences in the materials and properties of the elements they contain.

Corrosion Resistance

The corrosion resistance of galvanized steel is determined by the thickness of the zinc layer, the thicker the zinc layer, the better the corrosion resistance, for example, Z100 is suitable for general indoor environments, and Z275 can be used in the sea and industrial go. Stainless steel has excellent corrosion resistance and is suitable for marine, chemical, and high-humidity environments.

Strength

Both galvanized steel and stainless steel can be used as load-bearing structures and have good strength. However, the tensile strength and hardness of stainless steel are higher than galvanized steel and other metals.

Ductility

Galvanized steel has better ductility and workability and can be bent, stamped, cut and formed. Stainless steel is less ductile and more expensive to work with.

Appearance

The surface of galvanized steel is silver, with smooth, regular spangle, large spangle and other surface effects. Stainless steel has a rich appearance with brushed, mirror and matte finishes.

Weldability

The zinc layer of galvanized steel affects weldability, while stainless steel is susceptible to hot cracking and intergranular corrosion during the welding process. The weldability of both metals is average, with high demands being placed on the welding process, method, and material.

Heat resistance

Galvanized steel is generally heat-resistant, while stainless steel sheets are more heat-resistant. At high temperatures, there is a risk of the zinc layer peeling off, while most stainless steels can withstand high temperatures.

Comparison of Galvanized Steel and Stainless Steel Applications

The properties of the steel determine the application, galvanized steel with a rough surface is suitable for applications with low cosmetic requirements, while stainless steel with a smooth, shiny surface is used for applications with high cosmetic requirements.

Galvanized Steel Applications

- Architectural

- Decoration

- Manufacturing

- Appliances

- Piping

- Cables

Stainless Steel Applications

- Chemical

- Medical

- Food Packaging

- Aerospace

- Automotive

- Decorative

- Marine

- Kitchenware

Cost Comparison Between Galvanized Steel and Stainless Steel

The price of galvanized steel is 600-800 USD per ton, while the price of stainless steel is 1000-2000 USD per ton. The production process is simple, and the raw material is only cold rolled/hot rolled steel and zinc, which makes the raw material cost low, while stainless steel contains chromium, nickel, and other metal elements, which makes the raw material cost higher, and stainless steel is more difficult to process, which makes the processing cost higher. Therefore, galvanized steel is less expensive than stainless steel.

Which Is the Better Choice – GI Steel or Stainless Steel?

Galvanized steel and stainless steel both offer corrosion resistance and have their own strengths and weaknesses in different areas For example, stainless steel has excellent corrosion resistance, high strength, high-temperature resistance, sanitation, and aesthetics, but it is costly and difficult to work with, while galvanized steel is generally corrosion resistant, has a rough surface, but is low-cost, and has good plasticity.

Choose the metal material that best suits your project in terms of cost, application, and budget! Choose galvanized steel for low strength and high-temperature resistance, stainless steel for long life and high maintenance, strength, and aesthetics.

Where to Buy Galvanized Steel and Stainless Steel?

Are you looking for premium metal materials for your project? Wanzhi Group has galvanized steel, alloy steel coils, plates, strips and structural components of all types, starting from 10 tons, which can be produced according to your project design.

Products

All sizes of galvanized steel coil supply

All types of stainless steel coil supply

Factory

Wanzhi Factory is located in Binzhou City, Shandong Province, China, with 7 production lines and an annual production capacity of 600,000 tons, we can provide cutting, slitting, profiling, punching, bending, and other in-depth processing services.

If you are interested in galvanized steel, aluminum zinc-plated steel, color-coated steel, stainless steel, and other metal materials, please leave a message to tell us, and we can provide samples for you.