It is well known that the thickness of the zinc layer is the main factor affecting the price of galvanized metal, and usually the thicker the zinc layer, the higher the price of the steel, so shouldn’t we all go for high zinc galvanized/aluminum zinc coated steel? The answer is no! Today, let’s take a look at some of the different galvanized metal materials used in construction, household appliances, automotive manufacturing and other applications to see why zinc thickness is important, but not the thicker the better, and why the “right” is more important than the “thick”.

Zinc Coating Properties of Galvanized Steel / Galvalume Steel

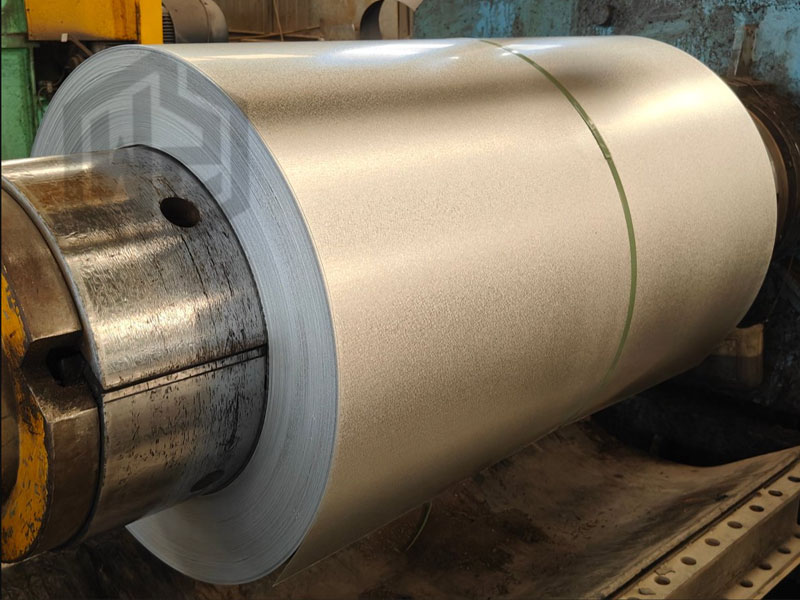

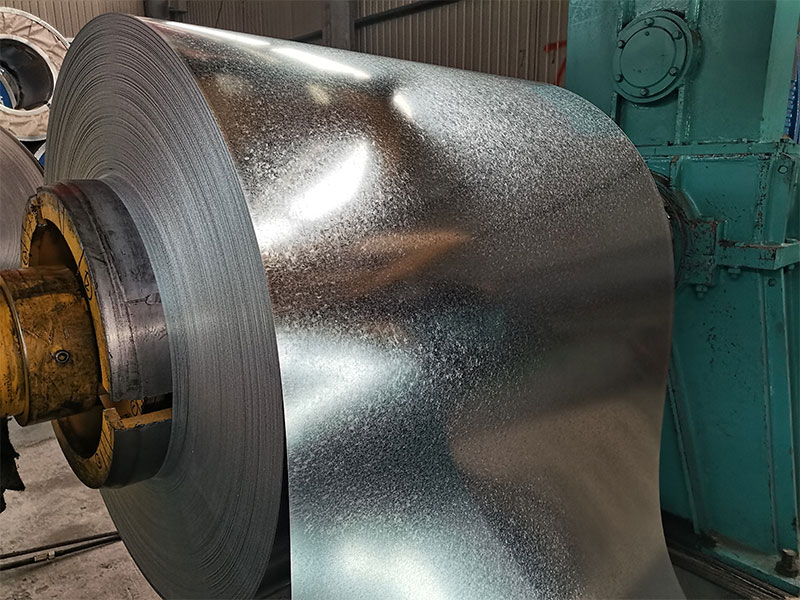

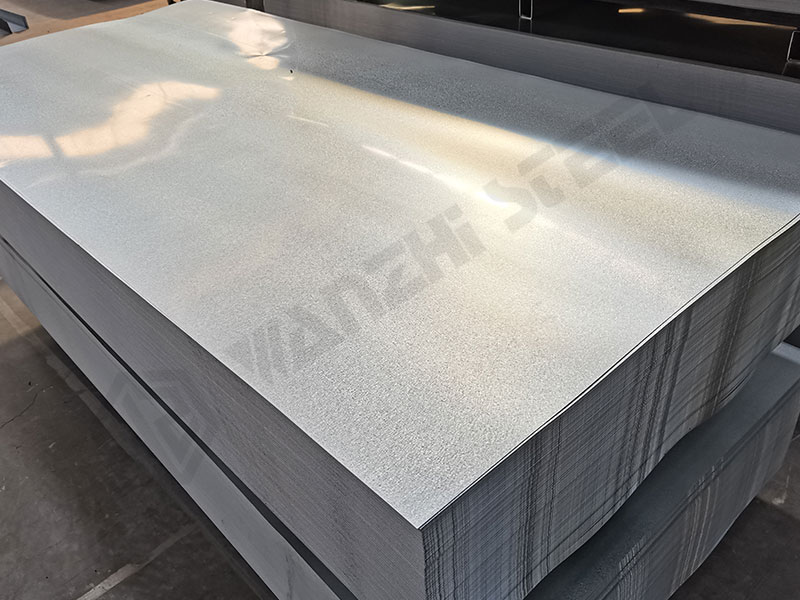

Galvanized metallic materials are coated steels with a steel/alloy steel substrate that is hot-dipped galvanized/electro-galvanized to form a uniform protective coating on the surface. Common metal coatings include zinc, aluminum-zinc , zinc-aluminum-magnesium, etc. Aluminum provides a physical barrier against corrosion and oxidation at high temperatures; zinc provides sacrificial anode protection; and magnesium provides self-healing.

- Sacrificial Anode Protection: When a scratch or cut occurs on the surface of galvanized/aluminum zinc plated steel, the zinc is preferentially corroded and dissolved, preventing rust from spreading around the damaged area.

- Physical Barrier: The surface of the coated steel is coated with a uniform, continuous layer of aluminum-zinc alloy in the steel, which forms a physical barrier that slows down the corrosion of the steel by environmental agents (oxygen, water molecules, corrosive ions).

- Processability: Thickness of coating, smoothness, and zinc pattern structure affect bending/stamping/welding/painting results.

- Appearance: Silver, bright silver-gray, zinc patterned appearance.

Zinc Thickness of Galvanized/Galvalume Steel

There are two common ways of expressing the thickness of the zinc coating. One is the mass per unit area: grams per square meter (g/m²) or ounces per square foot (oz/ft², 1 oz/ft² ≈ 305 g/m²). The other is the thickness of the plating (μm), the thickness of zinc is a key indicator of the protective capacity and cost of the plating, which profoundly affects several aspects of the steel:

Common markings

- Galvanized (GI): Z60, Z90, Z100, Z120, Z140, Z180, Z275 (the numbers represent the total zinc mass on both sides, e.g. Z120 ≈ 120g/m²).

- Galvalume (GL/55% Al-Zn): AZ60, AZ100, AZ150, AZ200 (e.g. AZ150 ≈ 150g/m² alloy layer).

Why is “right” More Important Than “thick”?

From a cost perspective, the thicker the zinc layer, the higher the cost, and the use of extra high zinc layers in normal environments can significantly increase the cost of a project, especially if the zinc layer provides corrosion resistance well beyond the life of the project or product, resulting in over performance. From a processing point of view, the later the zinc layer, the more difficult it is to process. High zinc coated steel is susceptible to cracking, chalking, porosity, spattering, etc. during bending/stamping/welding. From the coating point of view, galvanized/alloy coated steels are commonly used for pre-painted steels. The thicker the zinc layer, the poorer the adhesion of the coating, which can cause the paint layer to peel off.

Tips for Selecting the Zinc Coating on Galvanized/Galvalume steel

How to choose the right thickness? Select the most cost-effective metal-coated steel material by identifying the corrosion level of the environment in which it will be used!

- Normal dry indoor environments, e.g. residential, commercial buildings, etc., are low-corrosion environments (C1, C2), and the corrosion protection provided by galvanized steel Z60 to Z120 and aluminized zinc-coated steel AZ60 to AZ100 is sufficient.

- General industrial environments, e.g. industrial buildings, indoor areas with high humidity, etc., are medium corrosive environments (C3), where galvanized steel Z120~Z180 and aluminium zinc-coated steel AZ100~AZ150 can be selected.

- In highly polluted industrial and coastal areas, such as buildings/steel structures close to the coastline, chemical plants, etc., galvanized steel Z180~Z275+ or zinc-aluminized steel AZ150~AZ200+ is recommended.

Note: For steel exposed to chemicals, high temperatures, prolonged immersion, etc., customized ultra-high zinc coated steel or painted steel is available.

Standard Reference

Wanzhi Group produces galvanized steel, aluminum zinc coated steel and other metal coated steel in accordance with international standards such as GB, ASTM, EN, JIS and so on. The factory production line is certified by ISO9001 and ISO14001.

| Standard System | Galvanized Layer (g/m²) | Aluminum Zinc Plated Layer (g/m²) |

|---|---|---|

| China | GB GB/T 2518 | GB/T 14978 |

| USA | ASTM A653 | A792 |

| European Union | EN EN 10346 | EN 10346 |

Choosing the right metal-coated steel with the right zinc coating thickness, taking into account the life expectancy of the construction project and the product, as well as the manufacturing process, not only balances the project costs, but also reduces waste. What other corrosion resistant steels would you like to know about? Please let us know.