Matte Color-Coated Steel is a flagship product of Wanzhi Group. We manufacture and sell matte PPGI steel, matte color-coated aluzinc steel, matte aluminum, matte stainless steel, and more. Matte-coated metal materials feature a soft luster without glare, and reflected images are not visible. They serve as a common solution in many architectural and appliance applications where visual comfort, texture, and flaw concealment are prioritized.

Gloss Grading for Color-Coated Steel

Gloss is typically measured using a 60-degree gloss meter, with gloss values expressed in GU. Lower values indicate weaker light reflection properties. Matte finishes are explicitly defined as falling within the 25°–45° range.

| Gloss Level | 60° Gloss Range (GU) |

| High Gloss / Glossy | > 70 |

| Semi-Gloss / Satin | 40 – 70 |

| Matte / Flat | 25 – 45 |

| Low Matte / Eggshell | 10 – 25 |

| No Gloss / Soft Touch | < 10 |

What is “Matte” Color-Coated Steel?

Matte color-coated steel is a colored coated steel material produced by adding matting agents to the coating during the roll-coating process of organic coatings. Tiny matting agent particles within the coating cause light to undergo diffuse reflection. The reflected light is scattered in all directions, transforming concentrated “specular reflection” into soft “diffuse reflection,” thereby successfully “reducing” gloss.

- Features: Glare-free, non-blinding, conceals imperfections, premium texture.

- Applications: Widely used in office buildings, airports, stadiums, hospitals, schools, and other architectural settings.

- Drawbacks: Inferior stain resistance and cleanability compared to glossy color-coated steel.

Why Choose Matte Color-Coated Steel?

Visual Softness: When used over large areas, matte surfaces effectively prevent light pollution and glare, enhancing comfort.

Scratch and Fingerprint Resistance: Matte finishes better conceal minor imperfections, light scratches from transport/installation, and fingerprints, keeping building facades consistently pristine.

Versatile Applications: The matte texture seamlessly integrates with metals, stones, and woods, effortlessly complementing industrial, minimalist, rustic, and diverse design aesthetics.

Weather Resistance & Durability: Premium matte color-coated steel offers outstanding UV resistance, corrosion resistance, and weather durability.

Applications of Matte Color-Coated Steel

The construction and curtain wall sectors represent the largest and most iconic applications for matte color-coated steel sheets. Additionally, these sheets are utilized in interior decoration and design, transportation, home appliances and electronics, home building materials and furniture, as well as advertising signage.

- Exterior Walls and Roofing

- Interior Partitions

- Ceilings and Suspended Ceilings

- Home Appliance Housings

- High-End Furniture

- Automotive Interiors

- Wall and Partition Systems

- Ships and Cruise Liners

- Electronic Product Housings

- Advertising and Signage

Technical Standards and Certifications

Gloss Grading: Per HG/T2597-94 standards, the gloss level of matte color-coated panels must be controlled between 20-30. Values outside this range classify the material as flat or glossy.

Environmental Certifications: Must pass RoHS (Restriction of Hazardous Substances) and REACH (Registration of Chemicals) certifications.

Weather Resistance Testing: QUV accelerated aging test.

Color Difference: ΔE ≤ 3

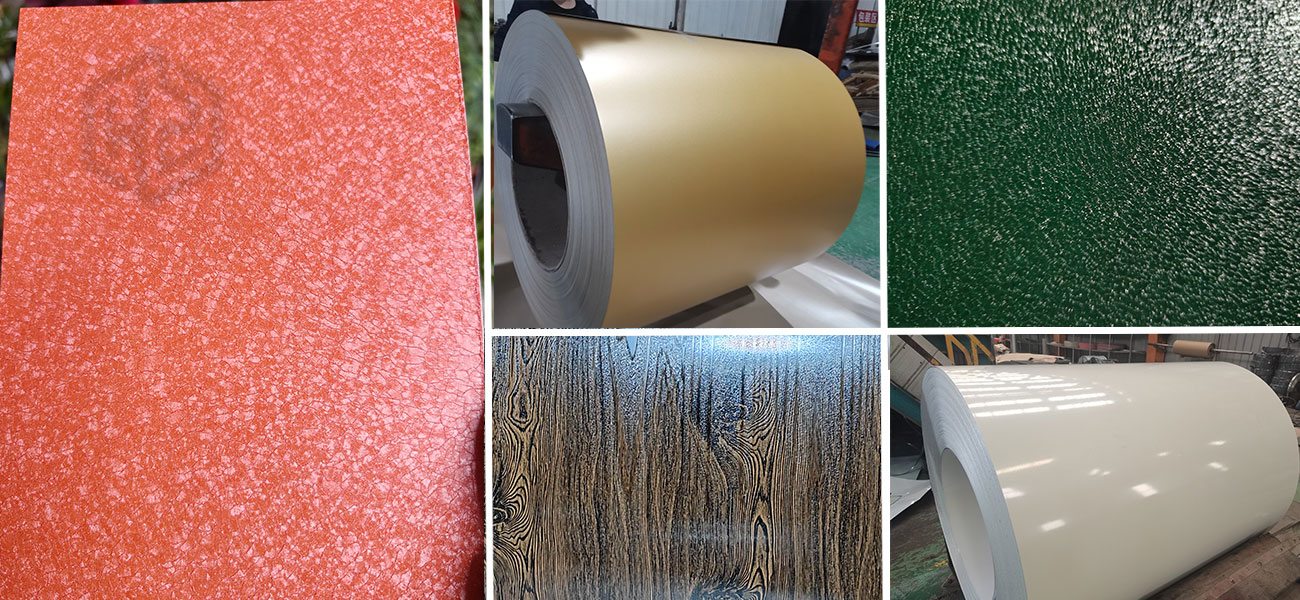

Wanzhi Group Color-Coated Steel Products

Wanzhi Group, as a professional supplier of color-coated metal, offers metal materials in various material grades and color shades. We provide OEM and ODM services. Contact us for a free quote.