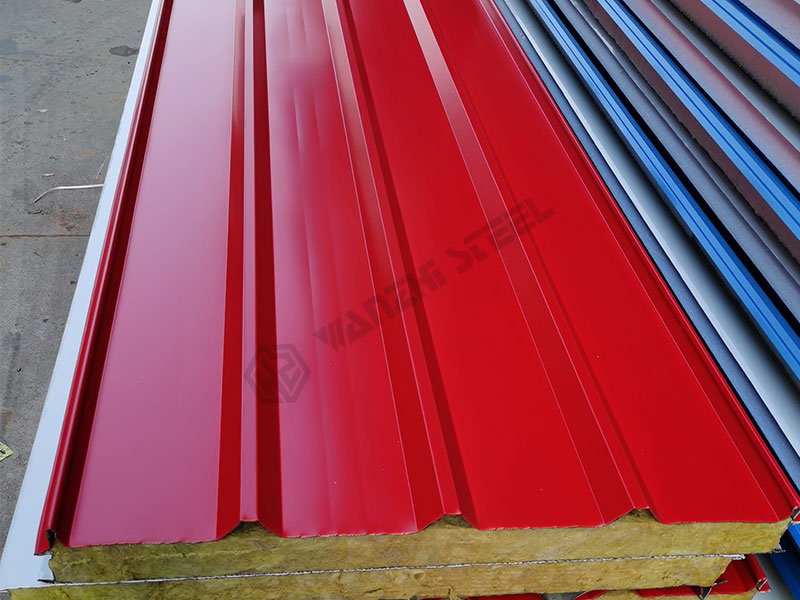

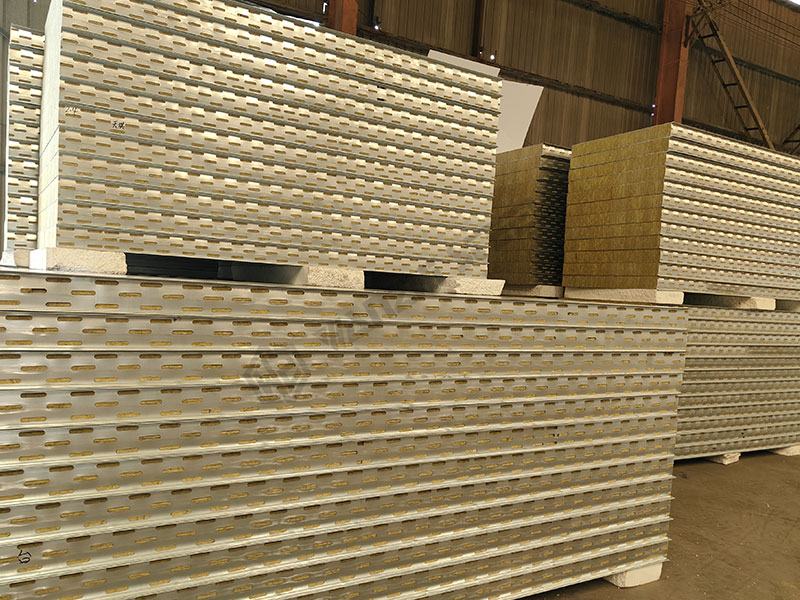

PPGI Sandwich panels are color-coated galvanized steel panels with an insulating material in the middle. PPGI steel has good corrosion resistance, workability, and aesthetics, and insulating materials such as puf and rock wool has sound and heat insulation characteristics.

Exterior Panels for PPGI Sandwich Panels

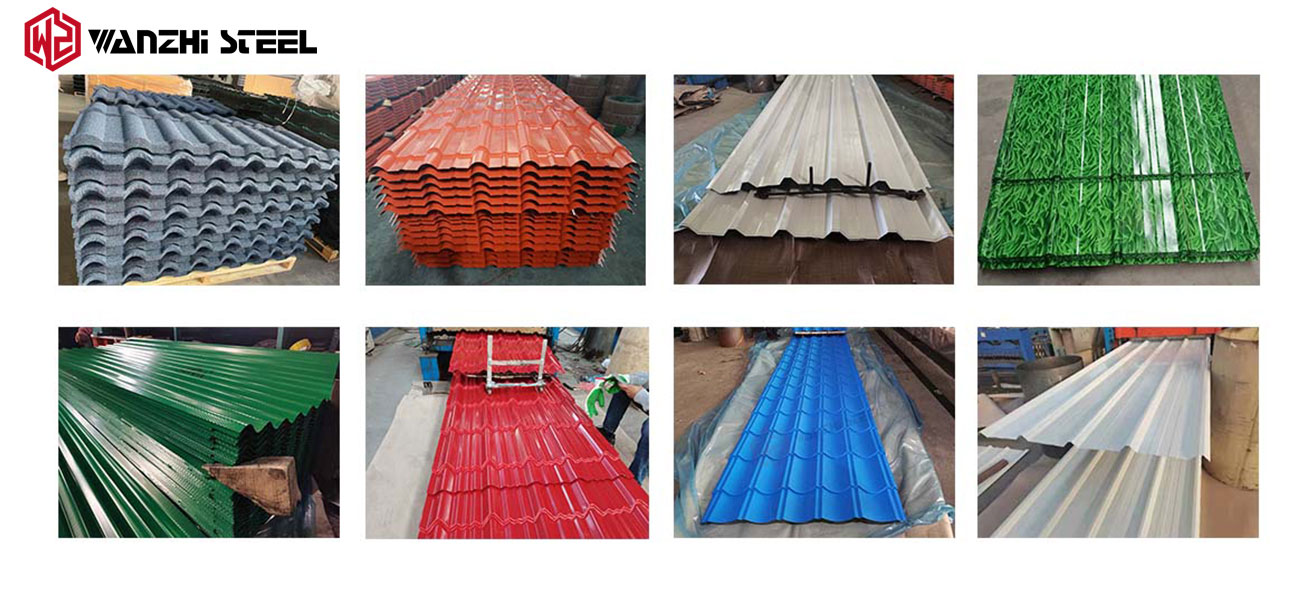

PPGI Sandwich Panels can be customized regarding structure, material, and surface effect. Wanzhi currently offers several panels such as steel, aluminum, and stainless steel. Surface structure: flat plate, corrugated sheet, ribbed plate, trapezoidal sheet, etc.

Steel sheet: galvanized steel, PPGI steel. Corrosion resistance, good weather resistance, low cost.

Aluminum sheet: aluminum alloy plate, corrosion resistant, lightweight, durable.

Stainless steel sheet: excellent corrosion resistance, corrosion resistant, anti-oxidation, high surface quality.

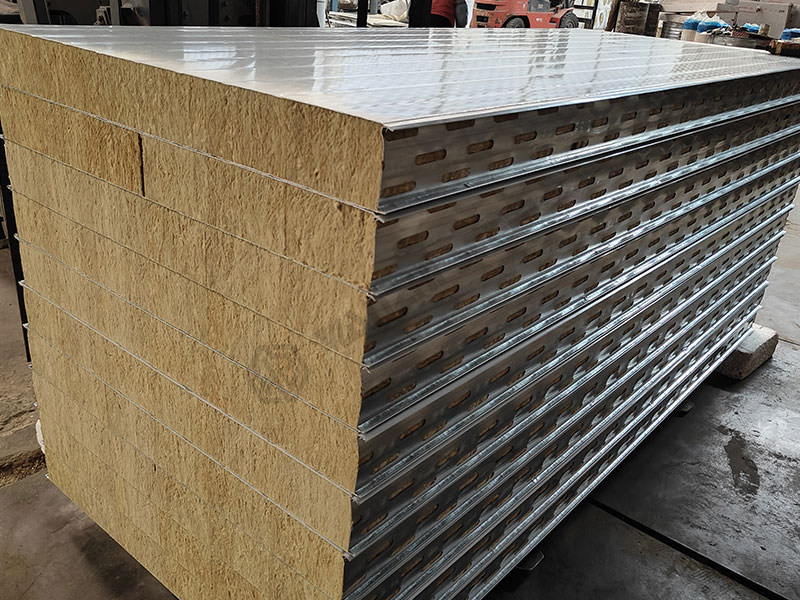

Core Material (Insulation) for PPGI Sandwich Panels

The core material of Sandwich Panels determines the structural strength of the PPGI panels as well as their acoustic and thermal insulation properties.

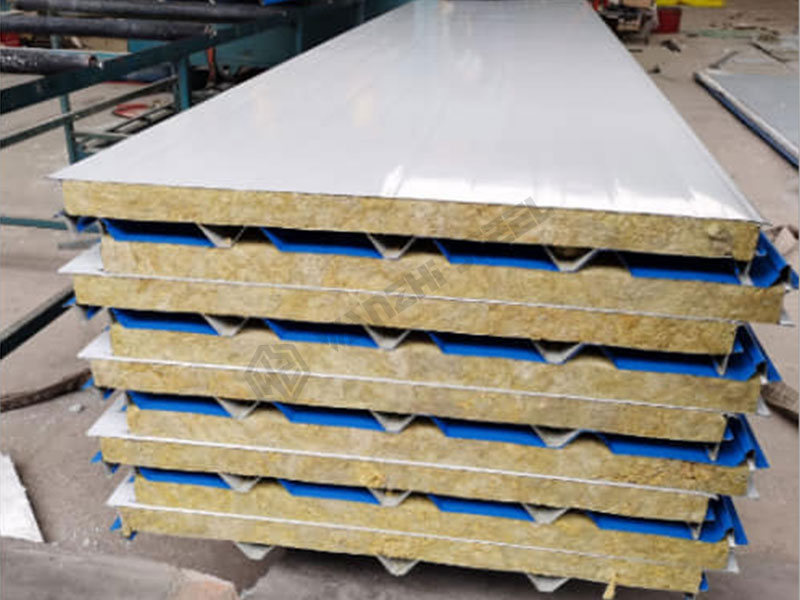

Applications for PPGI Sandwich Panels

PPGI Sandwich Panels can be used as roofing, shingles, enclosures, etc. in construction, transportation, and renovation applications.

Features and Benefits of PPGI Sandwich Panels

Sandwich panels with PPGI steel panels on the outside and insulation in the middle are aesthetically pleasing and practical. PPGI steel sheet are colorful, corrosion-resistant, durable, and weather-resistant, and the insulating material improves the panels’ sound insulation, thermal insulation, fire resistance, and structural strength.

Characteristics

- Multi-layer structure: It consists of the metal outer sheet (GI, PPGI) and insulating material.

- Lightweight and high strength: PPGI steel and insulation materials are relatively lightweight.

- Surface treatment: Coatings are available in PE/PVDF/SMP/HDP, and surface structures can be customized.

- Modular design: Customized according to requirements.

Advantages

- Good thermal insulation.

- Good sound insulation.

- Easy to install and use.

- Good durability.

- Beautiful and durable.

- With a certain degree of earthquake resistance.

- Flexible design.

- Wide range of uses.

Sandwich Panels Supplier

Wanzhi Group supplies all kinds of galvanized steel coils, steel sheets and color-coated steel coils and sheets, roofing sheets, and sandwich panels. We have several production lines and processing facilities. We can meet the demand for steel in different shapes and surface structures!

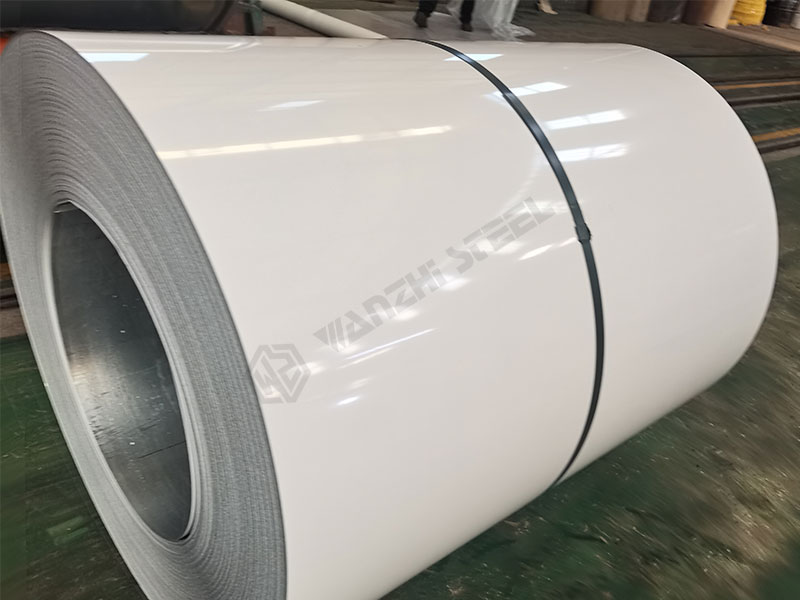

Coil production

Metal Sandwich panels are available in both galvanized steel and color-coated steel. Wanzhi Group has galvanized steel lines with zinc thicknesses ranging from 30-350g, as well as PPGI/PPGL lines with topcoats ranging from 10-40 microns and primers ranging from 5 to 20 microns. We can supply raw materials to different processing plants in different fields with a delivery time of 5–45 days.

Steel Sheet Processing

Of course, we can also provide finished PPGI Sandwich panels for projects. Wanzhi Group has a wide range of panels processing machines for various configurations in our factory, which can be customized according to your needs.

Panels Packaging

We attach great importance to the packaging of panels, Wanzhi Group’s packaging includes plastic film, moisture-proof paper, galvanized iron sheets, wooden pallets, etc. This effectively prevents the panels from being crushed and deformed during transportation, or from being exposed to moisture, making them unusable.

GI GL PPGI PPGL Sandwich Panels Price

Wanzhi is committed to providing customers with the most cost-effective GI/PPGI Panels, we emphasize on product quality while saving costs by improving production efficiency, to provide customers with the most competitive price. Welcome to leave a message to tell us the details of the PPGI Sandwich Panels you need, we will give you a free quote!

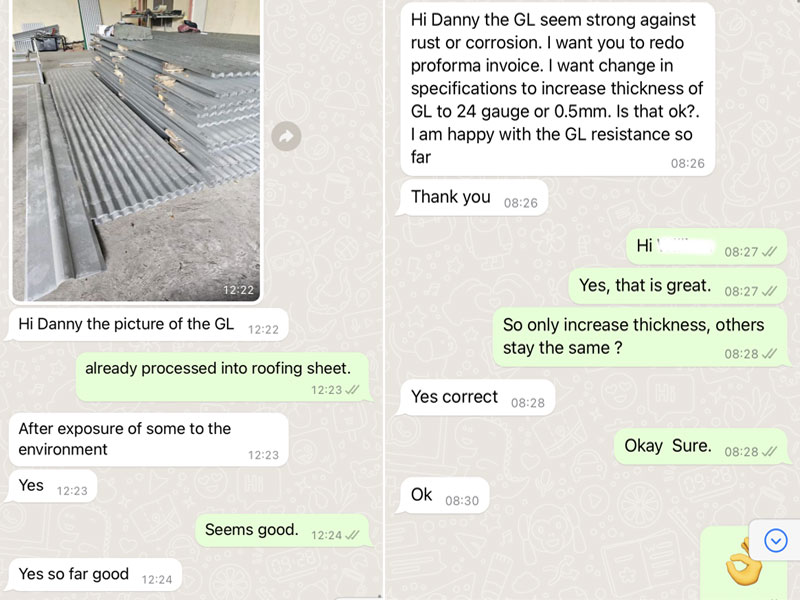

Customer Feedback

If you are looking for high-quality coated steel suppliers, then Wanzhi Group will be your best choice! See what Wanzhi Group’s customers have to say about our products and services!

Any questions about PPGI sandwich panels, PPGI roofing, or PPGI coil can be left in the comments! Our product managers are here to answer your questions!