PPGI Steel Sandwich Panel

Prefabricated steel structures are primarily composed of galvanized steel structures and pre-painted panels. Their greatest advantages lie in their short construction time, ease of assembly, lightweight, modularity, and portability. PPGI, with its diverse colors, finishes, and functions, is widely used for exterior siding, roof panels, and interior partitions.

Roofing System

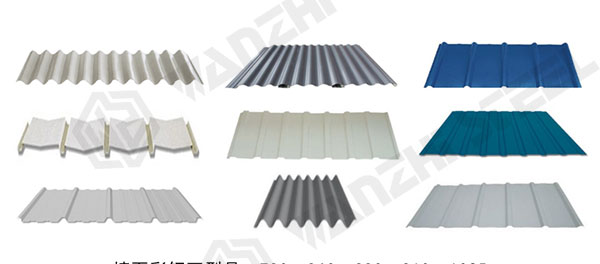

- Application: Roofing tiles or panels covering the entire roof.

- Common Forms: PPGI corrugated sheet, standing seam sheeting, etc., to ensure waterproofing and structural strength.

- Advantages: Load-bearing (snow/wind pressure), drainage (slope design), and temperature tolerance (outdoor temperature range -30°C to 80°C).

Wall Cladding System

- Application: The entire exterior and interior wall panels of a house.

- Common Forms: PPGI profiled sheeting or PPGI sandwich panels. Exterior siding prioritizes aesthetics and weather resistance. Advantages: Weather resistance (UV and acid rain resistance), corrosion resistance (salt spray and chemical gases in coastal and industrial areas), decorative properties (customizable colors, textures, and patterns).

Ceiling & Lining

- Applications: Indoor ceilings and wall linings.

- Common Forms: Thin PPGI sheets and carved PPGI panels, preferably in light colors (such as white and beige).

- Advantages: Fire resistance (Class A), sound insulation (≥30dB), and easy cleaning.

Other Areas

- Applications: Gutters, door and window covers, decorative blinds, eaves gutters, downspouts, etc.

- Common Forms: Special-shaped steel structures (such as arched roofs).

- Advantages: Protects the steel frame, aesthetically pleasing, and corrosion-resistant.

Why Choose PPGI Materials?

Corrosion Resistance: PPGI steel, used as roofing and wall cladding, isolates water, oxygen, and corrosive media, protecting the steel substrate from corrosion and rust.

Weather Resistance: PPGI surface coatings, applied with a roller coating, offer resistance to UV rays, high and low temperatures, and other weathering conditions. Decorative Features: The exterior can be customized to simulate the textures of wood, stone, or metal (such as brushed, mirrored, or other patterns) according to local customs.

Sound and Thermal Insulation: PPGI can be intercalated with materials such as polystyrene, polyurethane, and rock wool, which offer thermal, fire, and sound insulation properties, as well as load-bearing properties.

Processability: PPGI can be stamped, bent, rolled (e.g., corrugated board, C-shaped steel), and welded, and the coating resists cracking (elongation ≥ 15%).

Prefabricated Steel House Panel Selection Criteria

Wanzhi Group offers customized services, allowing you to select the appropriate prefabricated steel house material based on the local climate, the application environment, and functional requirements of the installation location.

Substrate Selection

- Strength Grade: Panels with a yield strength of ≥550 MPa are recommended for exterior walls/roofs, and G300-G450 grade panels are used for interior partitions.

- Galvanized Coating Weight: ≥275 g/m² for coastal/industrial areas, 30-120 g/m² for inland dry areas (determined by the environmental corrosion level).

Coating Type

- Exterior (exterior walls/roofs): PVDF (fluorocarbon) coating is preferred, HDP (highly weather-resistant polyester) is a secondary choice.

- Interior (partitions/ceilings): PE (polyester) or water-based coating is optional.

Coating Thickness

- Total coating thickness: 5-10 μm primer + 15-25 μm topcoat is recommended for exterior applications; 15-25 μm is recommended for interior applications.

Additional Functions

- Rockwool (RW) sandwich panels: Fireproof, heat-insulating, and soundproofing

- Polyurethane (PU/PIR) sandwich panels: Heat-insulating.

- Polystyrene (EPS) sandwich panels: Heat-insulating and low-cost.

- Glasswool (GW) sandwich panels: Fireproof, heat-insulating, lightweight, and soundproofing

Precautions for Using PPGI in Prefabricated Buildings

Insulation and Soundproofing: Single-layer steel panels offer poor insulation performance. Roofs and walls of container homes for residential and office use require composite panels (PPGI sandwich panels) made from PPGI steel and insulation wool (such as glass wool or rock wool).

Lightning Protection Design: Steel structures must have a comprehensive lightning protection and grounding system.

Detailed Treatment: Waterproofing of joints, such as ridges, eaves, corners, and door and window openings, is crucial. Specialized sealants, flashings, and edging must be used to ensure a secure fit. Transportation and Installation: Large-sized panels require care when transporting and hoisting to avoid bumps and scratches on the coating, which can compromise its corrosion resistance.

PPGI color-coated steel serves as a protective barrier, providing insulation, decoration, waterproofing, and fire protection in the production and processing of prefabricated steel structures. It perfectly addresses the core requirements of prefabricated buildings: durability, aesthetics, affordability, and construction efficiency. Contact Wanzhi Group to customize your prefabricated home!