Color-coated metal (PPGI, PPGL, PPAL, Color-coated stainless steel) commonly uses High Durability Polyester (HDP) and Silicone Modified Polyester (SMP) coatings as the most mainstream options between standard polyester and top-tier PVDF. Both share similar costs and equivalent corrosion resistance lifespans, both belonging to mid-to-high-end organic coatings for outdoor use. However, HDP-coated sheets are gradually replacing SMP-coated sheets. Let’s explore why!

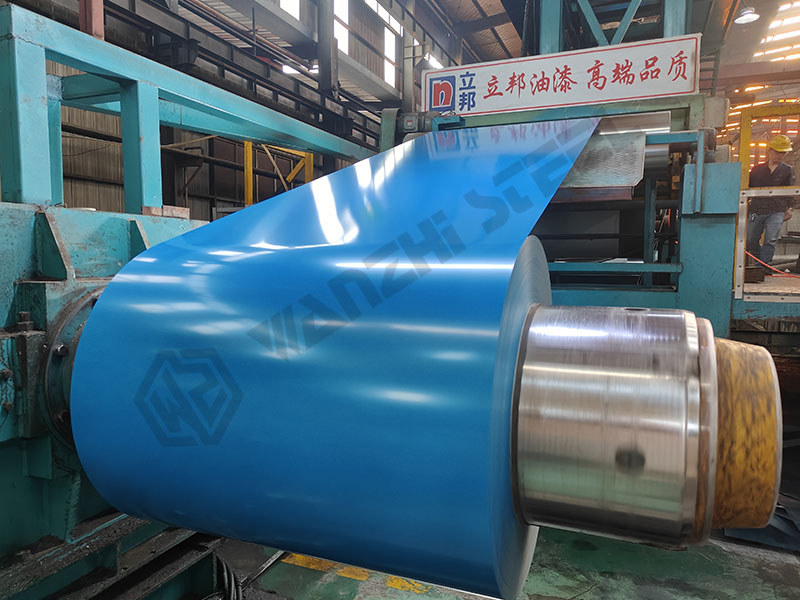

High Durability Polyester Coating (HDP Coating)

High Durability Polyester (HDP) represents an upgraded version of polyester coatings. It is enhanced through optimized resin molecular structure, the use of more weather-resistant curing agents, and a more stable pigment system. HDP-coated steel offers superior flexibility and outstanding UV resistance, making it particularly suitable for buildings and other applications requiring multiple processing steps in temperate and subtropical outdoor environments.

Finished Products

- HDP Prepainted Galvanized Steel / HDP PPGI Steel

- HDP Prepainted Galvalume Steel / HDP PPGL Steel

- HDP Prepainted Aluminum Steel / HDP PPAL Steel

Performance Characteristics

- Weather Resistance: Outdoor durability spans 10-15 years, with superior color retention compared to polyester coatings.

- Processability: Exceptional coating flexibility accommodates deep processing like roll forming and bending.

- Cost-Effectiveness: The most economical coated metal solution for mid-to-high-end construction and industrial applications.

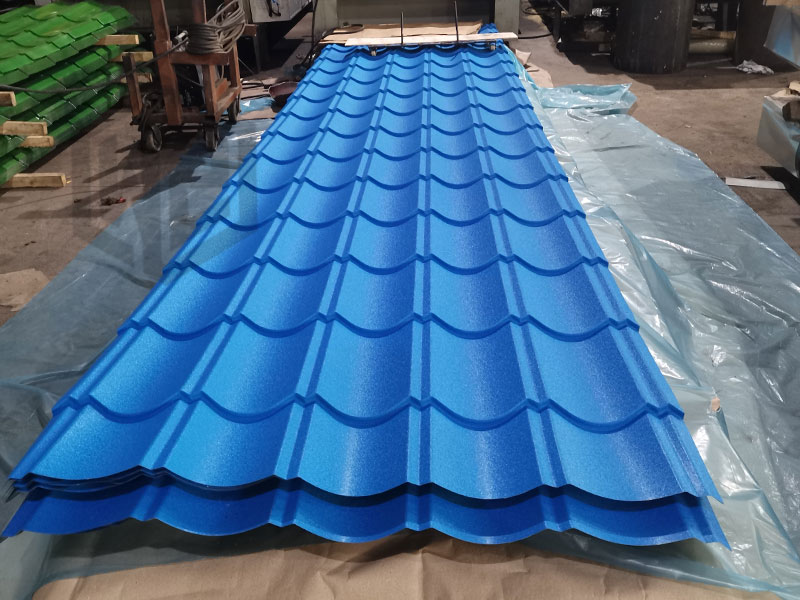

Applications

- Walls/roofs/exterior walls of industrial plants and civil buildings; light steel villa enclosures; canopies and carports;

- Steel structure plants and warehouses;

- Outdoor equipment housings; storage racks; agricultural greenhouse frames;

- Home appliance casings (e.g., refrigerator and washing machine side panels)

Silicone Modified Polyester Coating (SMP Coating)

Silicone Modified Polyester (SMP) is a composite coating system created by copolymerizing polyester resin with organosilicon resin, incorporating organosilicon components into the polyester matrix. SMP-coated panels exhibit enhanced weather resistance and heat resistance, though they offer limited flexibility. They are suitable for roofing, walls, structural components, steel windows, and automotive applications in high-altitude regions, areas with industrial pollution, and coastal zones with light salt spray.

Finished Products

- SMP Prepainted Galvanized Steel / SMP PPGI Steel

- SMP Prepainted Galvalume Steel / SMP PPGL Steel

- SMP Prepainted Aluminum Steel / SMP PPAL Steel

Performance

- Weather Resistance: Outdoor durability exceeding 10-15 years, with superior resistance to chalking and cracking compared to HDP.

- Heat and Chemical Resistance: Strong short-term resistance to high temperatures, industrial acids/alkalis, and solvent corrosion.

- Abrasion Resistance: High coating hardness and excellent wear resistance, though flexibility and deep-drawing performance are slightly inferior to high-weathering polyester coatings.

- Stain Resistance: Excellent self-cleaning capability of the coating.

Applications

- Roofing and exterior walls of buildings in high-altitude areas with intense UV exposure, heavy industrial zones, and coastal regions

- Protective covers for outdoor chemical equipment

- External cladding for high-temperature pipelines

- Container side panels

- Outdoor installations such as solar panel backsheets

- Air conditioner outdoor unit enclosures

HDP Coating VS SMP Coating

Why does Wanzhi Group recommend HDP coating for color-coated metal customers? For most conventional industrial and civil building applications in inland regions, Wanzhi Group advises clients to procure HDP-coated PPGI/PPGL/PPAL material. High-weatherability polyester fully meets the requirements of the majority of application scenarios, making it a cost-effective choice.

| Dimension | Standard Polyester (PE) | High Weather-Resistant Polyester (HDP) | Silicone-Modified (SMP) |

| Weathering Lifespan | Short (5-8 years), prone to light loss and powdering | Excellent (10-15 years), good in light and color retention | Extremely good (over 10-15 years) |

| Cost | Lowest | Moderate, highest cost-effectiveness | Moderate |

| Long-Term Maintenance Cost | High (requires frequent maintenance or replacement) | Low (significantly reduces maintenance) | Low |

| Processing Performance | Good | Good (comparable to PE) | Fair (especially for deep stamping) |

| Suitable Scenarios | Short-term buildings, indoor use | Most outdoor buildings, industrial plants | Non-repeatedly processed steel structures, extreme environments |

In addition to SMP and HDP coatings, common coatings for color-coated materials include PE and PVDF. In the next installment, we will delve into the characteristics and applications of polyester and polyvinylidene fluoride coatings. What topics interest you? Feel free to leave a comment and let us know.