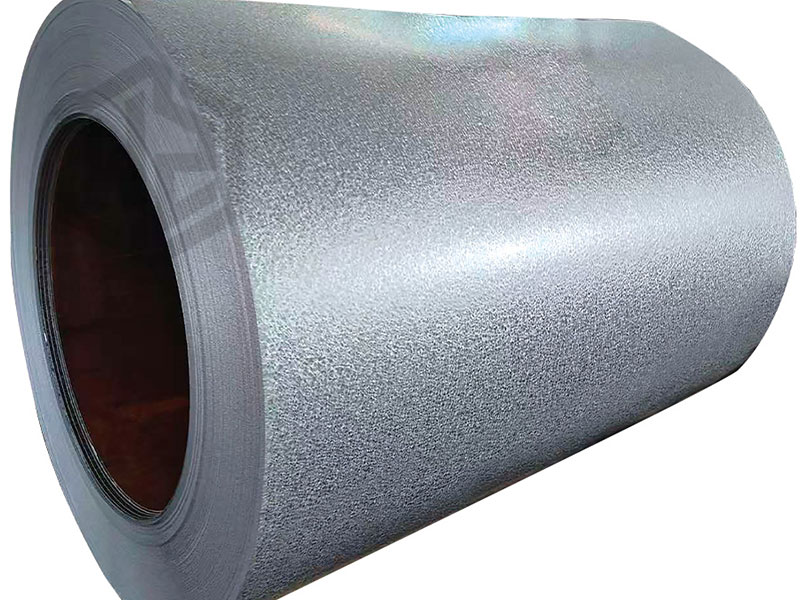

Aluminized steel is a composite material formed by coating carbon steel with aluminum or aluminum-silicon alloys via a hot-dip coating process. Based on the coating composition, it is categorized into pure aluminum-coated steel (≥98% Al + trace amounts of Si) and galvanized steel (55% Al, 43.4% Zn, 1.6% Si). Wanzhi Group manufactures and sells pure aluminum-coated steel coils up to AS120 in thickness and galvanized steel coils up to AZ150 in thickness, in accordance with EN 10346.

Aluminized Steel for Sale

The primary components of the DX51D+AS80/120 aluminized steel are aluminum and silicon, with an aluminum content of 89%-92% and a silicon content of 8%-11%. A higher aluminum content improves the sheet’s heat resistance, while a higher silicon content improves its corrosion resistance. Wanzhi Group can provide customized solutions based on application requirements, such as automotive exhaust pipes, oven components, and heat exchangers, which are subject to long-term high-temperature environments, as well as building facades, roofs, billboards, and refrigerated containers, which require long-term rust protection.

Aluminized Steel VS Aluminum Material

| Characteristic | Aluminized Steel | Aluminum |

| Substrate | Low carbon steel + pure aluminum or aluminum-silicon alloy | Pure aluminum or aluminum alloy |

| Density/Weight | Heavier | Lightweight |

| Strength | High | Lower |

| Corrosion Resistance | Excellent | Excellent |

| High-Temperature Resistance | Excellent | Average |

| Thermal/Electrical Conductivity | Lower | Excellent |

| Workability | Weldable, Stamped | Excellent |

| Cost | Medium | Higher |

| Typical Applications | Automotive exhaust pipes, oven interiors, chimneys, heat exchangers | Aircraft parts, door/window frames, cans, radiators |

Aluminized Steel VS Galvanized Steel VS Galvalume Steel

| Characteristic | Aluminized Steel | Galvanized Steel | Galvalume Steel |

| Coating Composition | Pure aluminum or aluminum-silicon alloy | Pure zinc | 55% aluminum + 43.4% zinc + 1.6% silicon |

| Corrosion Mechanism | Aluminum oxide film prevents corrosion | Zinc sacrificial anode protection | Aluminum barrier + zinc sacrificial anode dual protection |

| Atmospheric Corrosion Resistance | Resistant to SO₂/acid rain | Susceptible to white rust in humid environments | 2-6 times the lifespan of galvanized steel |

| High-Temperature Resistance | Oxidation resistant up to 800℃ | Zinc layer melts and fails above 200℃ | Silicon improves heat resistance, up to 315℃ |

| Edge Protection | Weak | Strong | Strong |

| Appearance | Silver-gray matte | Bright silver/zinc flower texture | Silver-white with glitter pattern |

| Cost | Medium to high | Lowest | Lower than aluminized steel |

| Weldability | Poor | Good | Medium |

| Applications | High-temperature components | Roofing, supports, guardrails | Roofing/exterior walls, home appliance panels, automotive panels |

Applications

Aluminized steel coils’ excellent resistance to ammonia, acid, alkali, and grease corrosion, high temperature resistance, and high reflectivity make them widely used in the automotive, industrial, home appliance, energy, agricultural, and construction industries.

High-Temperature and Heat-Resistant Applications

- Automotive exhaust pipes/mufflers/turbocharger housings/fuel tank insulation covers; industrial heat exchangers/radiant tubes; oven cavities/grills/microwave oven components/rice cooker housings; chimneys/heat exchangers/incinerator linings, etc.

Building and Infrastructure

- Fireproof panels; high-temperature workshop roofs; billboards, light boxes, outdoor seating; corrosive gas enclosures; photovoltaic backsheets; etc.

Energy and Chemicals

- Petroleum pipelines; chemical containers; flue gas treatment ducts; and high-temperature sterilization equipment linings.

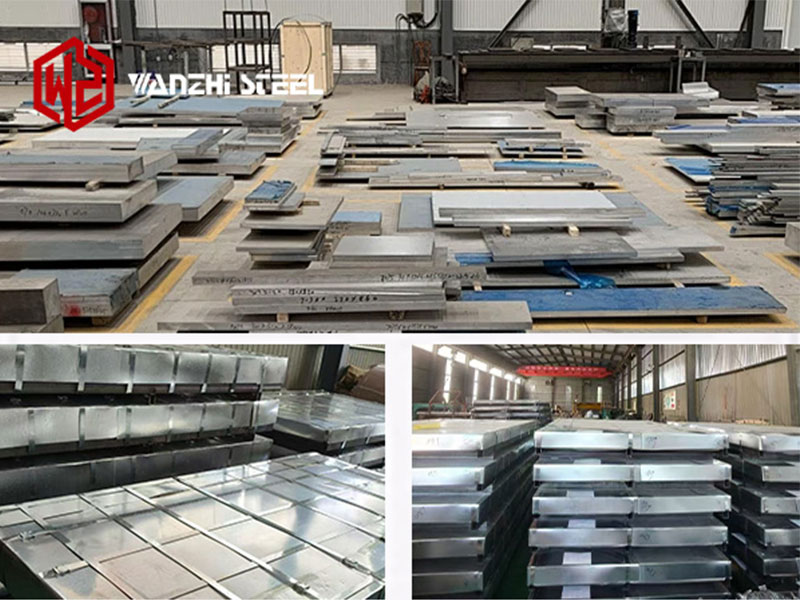

Aluminized Steel Factory – Wanzhi Group

Wanzhi Group manufactures aluminized steel sheet and coil, offering slitting, flattening, and bending services. Located in Boxing County, Binzhou City, Shandong Province, China, our galvanized factory is ISO9001 and ISO14001 certified. We provide quality inspections and full-process certification support from third-party organizations such as SGS and TÜV (from material testing to factory audits).

Aluminized steel combines the strength of steel with the heat and corrosion resistance of aluminum, making it an ideal material for high-temperature and corrosive environments.