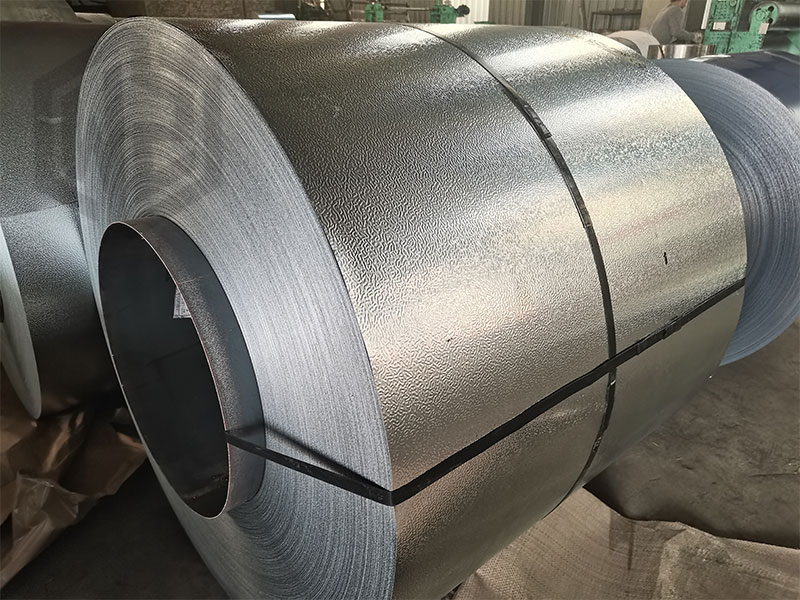

Embossed galvanized steel sheet is a metal panel that combines anti-slip, decorative, and corrosion-resistant functions. Wanzhi Group offers substrates such as GI, GL, ZAM, and stainless steel, along with embossed surfaces featuring geometric patterns, natural decorations, and special custom designs. These products provide coated steel OEM and ODM services for applications in the construction, home appliance, and transportation industries.

Embossed Types

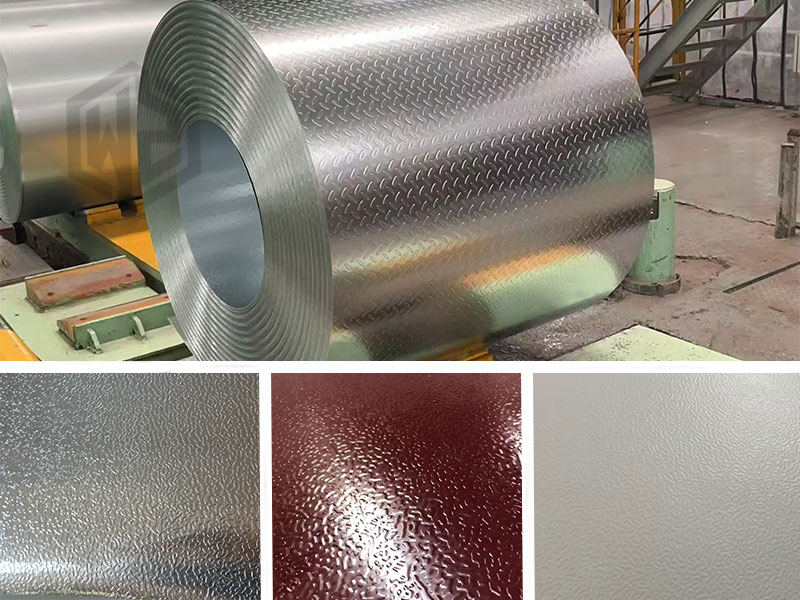

Embossed galvanized steel sheets feature various surface effects such as Diamond, Leather, Pebble, and Woodgrain. In different application scenarios, they offer functions such as anti-slip, decorative, scratch-resistant, enhanced rigidity and bending strength, sound absorption, and natural material simulation.

- Diamond/Hexagonal Patterns: The most classic functional embossing, featuring diamond grids or hexagonal honeycomb structures.

- Wave/Stripe Patterns: Continuous waves or parallel stripes.

- Dot Matrix Patterns: Uniformly distributed raised dots (round or square).

- Wood grain imitation: Reproduces the growth rings and texture of wood through embossing.

- Stone grain imitation: Simulates the mottled texture of marble or granite.

- Leather grain imitation: Features the delicate raised and recessed texture of leather.

- Hidden texture: Micron-level micro-texture.

- Thermal conductivity texture: Specially arranged grooves or raised patterns.

Embossed Galvanized Steel Sheet Specification

Embossed galvanized steel sheet is a coated metal material that combines “galvanized corrosion protection + embossing functionality.” Galvanized steel provides mechanical properties and corrosion resistance. It consists of a carbon steel substrate and a coating layer. Wanzhi Group offers various combinations, such as cold-rolled steel/hot-rolled steel + galvanized layer/ aluminum-zinc coating/zinc-aluminum-magnesium coating, etc., which can be customized for specific application scenarios.

Base Material

Steel Grade: Primarily low-carbon steel (e.g., Q195, Q235, SPCC), with carbon content <0.25%.

Chemical composition: C (carbon) ≤0.25%, Mn (manganese) ≤1.2%, Si (silicon) ≤0.1%, S/P (sulfur/phosphorus) ≤0.05%.

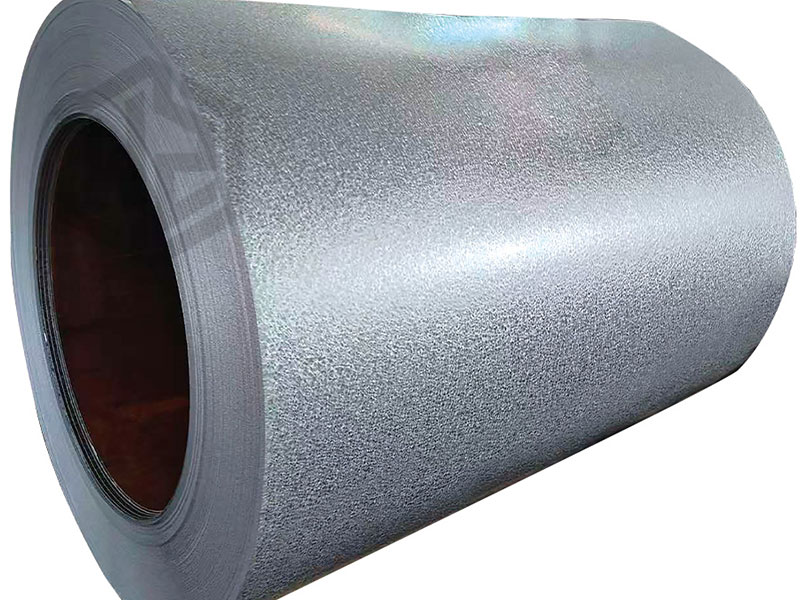

Galvanized Coating

Hot-dip galvanizing (GI): Zinc layer thickness 50–350 g/m², high corrosion resistance.

Electrogalvanized (EG): Zinc layer thickness 10–50 g/m², low cost.

Galvalume (GL): Zinc layer thickness 100–150 g/m², Al 55% + Zn 43% + Si 1–2%.

Zinc-Aluminum-Magnesium (ZAM): New coating (Zn+Al+Mg), zinc layer thickness 100–300 g/m².

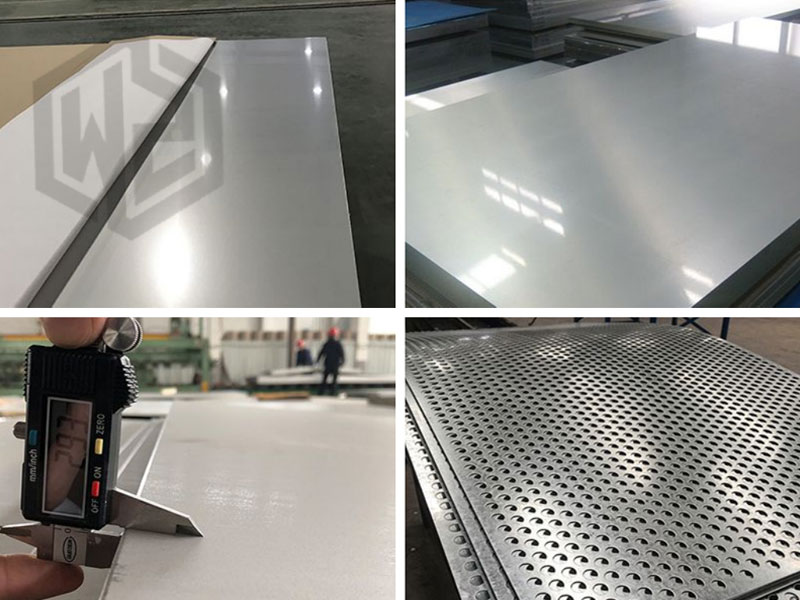

Specification

| Material | SGCC,S350GD+Z,S550GD+Z,DX51D,DX52D,DX53D, etc |

|---|---|

| Thickness | 0.12mm-6mm |

| Width | The conventional width below 0.5mm is 1000mm, 1200mm, and above is 1000, 1250mm |

| coil weight | 8-10 tons /customized |

| Tolerance | "+/-0.02 mm |

| Substrate Type | Hot rolled coil, Cold rolled coil |

| Surface structure | Zero spangles, Small spangles, Regular spangles, Big spangles |

| Zinc layer thickness | 30g/㎡-275g/㎡ (Z275/G90) |

| Standard | AISI, ASTM, BS, GB, JIS |

| Implementation standards | GB/T2518 GB/T25052, EN10346, JIS G3302, ASTMA653 |

| Certificates | SGS, ISO 9001,CE |

Further Processing

Wanzhi Group offers secondary processing services for embossed galvanized steel sheets, including stamping, bending, welding, cutting, and painting.

- Stamping processing: Embossed sheets with a pattern depth ≤0.5mm can be processed via stamping forming.

- Bending processing: Bending along the embossed pattern direction can prevent cracking of the embossed layer.

- Welding processing: Welding is performed using laser welding/resistance welding.

- Cutting Processing: Laser cutting is recommended for thin sheets, and plasma cutting is recommended for thick sheets.

- Surface Treatment: Painting and coating can be performed before or after embossing.

Embossed Galvanized Steel Sheet Advantage and Application

Embossed galvanized steel sheet is slip-resistant, corrosion-resistant, easy to clean, and effectively hides surface scratches while providing excellent drainage and heat conduction properties. It is widely used in building exteriors/roofs, interior decoration, transportation, industrial equipment, furniture, and home appliances.

Advantages

- Strong corrosion resistance: The galvanized coating (hot-dip galvanizing/electrogalvanizing) provides basic corrosion protection. The embossing process does not affect the integrity of the zinc layer, ensuring long-term use in outdoor or humid environments.

- Functional versatility: By replacing the embossing rollers, different pattern types (geometric/natural/custom) can be quickly switched, accommodating diverse application requirements.

- Good processing adaptability: The elongation rate of embossed steel plates is ≥18%, allowing for secondary processing such as stamping, bending, and welding without affecting the pattern structure.

- Structural reinforcement: Embossing enhances stiffness.

- Functional expansion: Anti-slip, noise reduction, decoration, etc.

- Cost-effective: Compared to natural materials such as solid wood and stone, as well as alloy materials like stainless steel, embossed galvanized steel plates offer lower costs.

Application scenarios

- Roofs, vehicle floors, industrial plant floors (high slip resistance).

- Appliance liners (refrigerators, washing machines), warehouse shelves (preventing goods from sliding), toolbox liners.

- Building exteriors, interior ceilings, furniture surfaces (cabinet doors, tabletops).

- Commercial space walls (shopping malls, hotels), landscape decoration (railings, flower boxes), art installations.

- Appliance housings (microwave ovens, ovens), automotive interiors (door panels, center consoles), high-end packaging materials.

- Smartphone backs (metal materials), high-end appliance panels (refrigerators, air conditioners), digital product housings.

- Heater housings, water heater liners, industrial heating equipment.

- Equipment housings (e.g., machine tools, conveyor belts), kitchen countertops (oil stain prevention), drain cover plates.

Embossed Galvanized Steel Sheet Customized Services

Wanzhi Group provides embossed steel OEM services. We have our own factory and steel coating production lines, and are certified under ISO9001, ISO14001, and ISO45001 standards. We offer tailored solutions and free samples.

Customization Scope

- Pattern Customization: Provide CAD drawings → Roller engraving (precision ±0.05mm)

- Coating Upgrades: Alloy coating, organic coating.

- Performance Enhancement: Insulation-type, antibacterial-type

Factory – Embossed Galvanized Steel Sheet

Our factory, Shandong Wanzhi Steel Co., Ltd., is located in Boxing County, Binzhou City, Shandong Province, China. The factory has three metal-coated steel production lines and four painted steel product processing production lines, with an annual production capacity of 600,000 tons. We have provided steel raw materials and finished products to customers in over 100 countries and regions worldwide.