Galvalume AZ150 – The ideal corrosion resistant steel solution for projects with high corrosive environments, high temperature scenarios and long life requirements. Aluminized zinc coated steel with Al₂O₃ passivation film + cathodic protection double protection, widely used in extreme environments for roofs, walls, industrial buildings because of its high strength, super corrosion resistance, high temperature and oxidation resistance, and cost-effective properties!

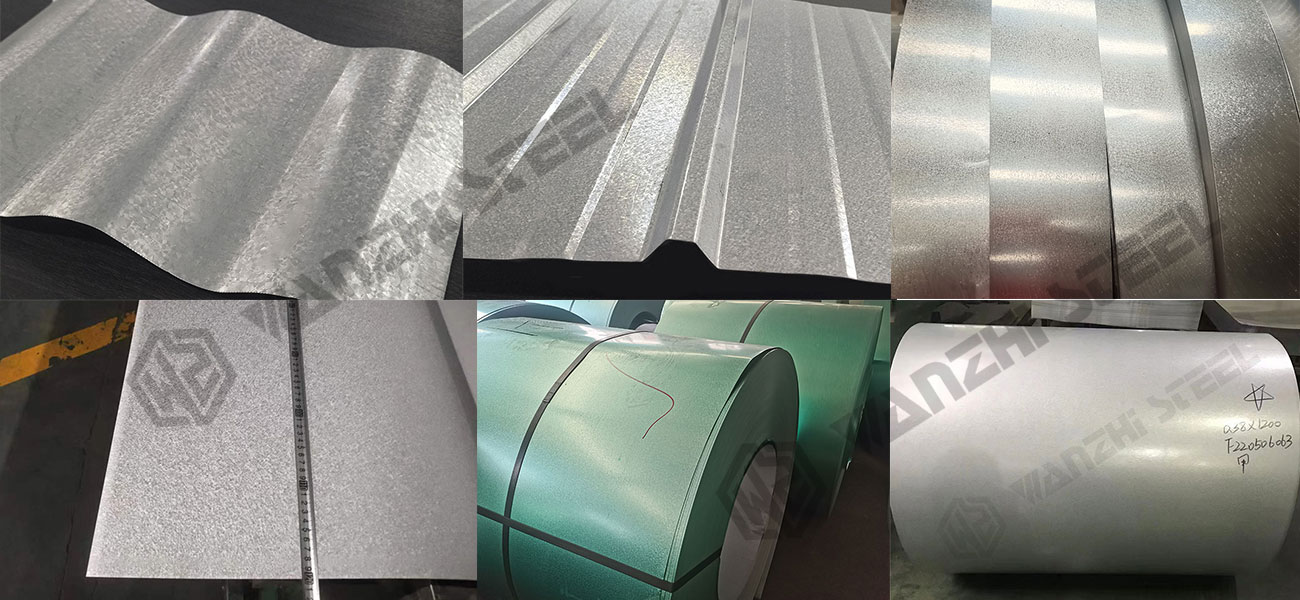

Wanzhi – Coil Galvalume AZ150

Wanzhi Group produces and sells galvalume steel coil and sheet, including AS 1397 G550+AZ150, JIS G3321 AZ150, DX51D+AZ150, etc., which are in accordance with the international standards of ASTM A792/EN 10346/GB/T 14978, etc. Meanwhile, We also provide one-stop service, including OEM, ODM service for galvalume steel coil and sheet, including galvanized/aluminized zinc/zinc-aluminum-magnesium coated steel.

Specification

| Parameter | Regular Specifications | Special Custom Range | Tolerance Standard |

| Thickness | 0.3-2.0mm | 0.15-3.0mm | ±0.03mm (≤1mm)/±3% (>1mm) |

| Width | 600-1500mm | 300-2000mm | ±2mm |

| Length | 1000-6000mm | 500-12000mm | +10mm/-0mm |

Performances

| Item | Parameter Value |

| Substrate Type | Low Carbon Steel (DX51D/DX52D) |

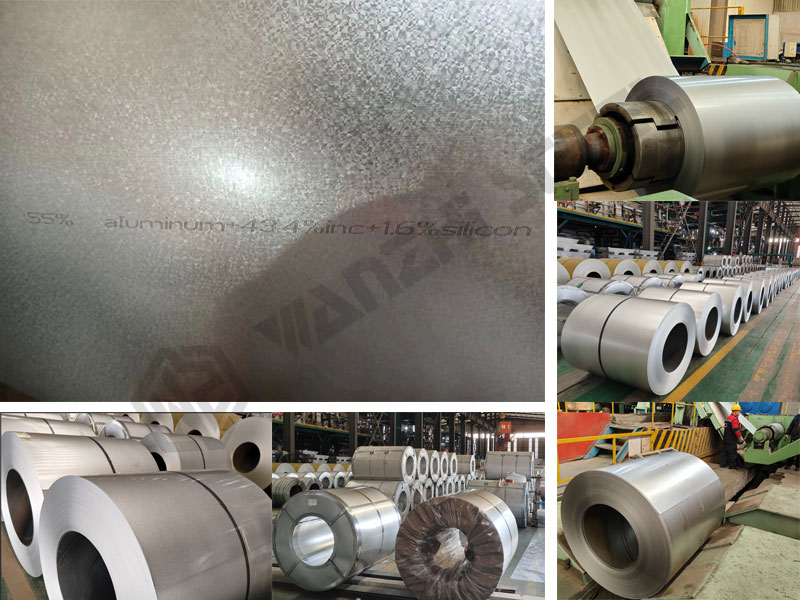

| Coating Composition | 55% Al – 43.4% Zn – 1.6% Si |

| Coating Weight | 150 g/m² |

| Corrosion Resistance Equivalent | ≈ 2-6 times that of DX51D Z275 galvanized steel |

| Heat Resistance Limit | Long-term: 315°C / Short-term: 480°C |

| Reflectivity | ≥75% (solar reflectance) |

| Salt Spray Test | 3000+ hours without red rust |

| Edge Corrosion Protection | Self-healing (Zn migration) |

Surface Treatment

- Smooth surface: Roller flattening + passivation

- Phosphating: Phosphate conversion film to provide corrosion resistance

- Fingerprint resistance treatment: Film coating, fingerprint-resistant residue

- Coating: Epoxy primer + polyester/fluorocarbon/high weathering polyester/silicone-modified polyester topcoat

International Standard

- American Standard: ASTM A792 AZ150

- European Standard: EN 10346 AZ150

- National Standard: GB/T 14978 AZ150

Cases/Projects

We have supplied premium galvanized/galvalume steel for commercial hospital projects in Liberia, many roofing sheet factories in Latin America, and gutter manufacturing in Central Asia.

Galvalume AZ150 Application Scenarios

Galvalume AZ150 has high tensile strength and durability, and can be made into various kinds of aluminum-zinc coated steel parts by bending, painting, and forming, which are widely used in high temperature/high humidity/high salt spray in the fields of construction, industry, transportation, and household appliances.

Construction

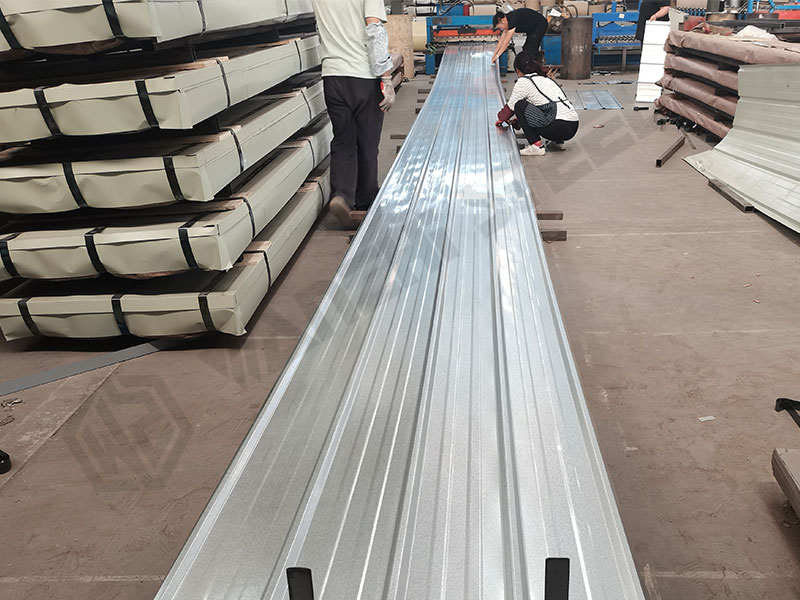

Galvalume coated steel is often used in the construction field as roofs of hotels/houses, walls of chemical plants, silos, drainage systems, chimney stacks, etc. Medium-thickness galvalume coated steel sheets in the range of 0.6-1.5mm can be bent to make various kinds of concave-convex galvalume corrugated sheets, which are widely used for roofs and walls of buildings.

Industry and Transportation

The aluminum in Galvalume has excellent high temperature resistance and is often used in industry and transportation as automobile exhaust pipe guards, truck fuel tanks, photovoltaic mounts, heat exchanger housings, coastal bridge guardrails, etc. Among the most popular industrial manufacturing plates are high temperature resistant zinc-aluminum plated flat plates, zinc-aluminum plated U-ribbed plates, etc.

Galvalume AZ150 Advantages

Galvalume AZ150 combines the advantages of mild steel, zinc and aluminum elements to provide excellent resistance to salt spray + high reflective cooling/salt spray/chemical gases/acidic and alkaline gases/ultraviolet aging.

Features

Corrosion Resistance:

Galvalume AZ150 has 2-6 times the corrosion resistance of galvanized steel with the same plating thickness, with the dual protection of the barrier function of aluminum and the sacrificial protection function of zinc.

Excellent heat resistance:

regular zinc-aluminized steel sheets can be used for long periods of time at 315°C, a much higher service temperature than galvanized steel sheets.

Excellent reflective properties:

Aluminum-zinc steel sheet has a reflectivity of more than 0.70, reflecting heat and light twice as much as galvanized steel, making it an ideal energy-saving building material.

Excellent Mechanical Properties:

AZ 150 Aluminized Zinc Plate has a yield strength of 230-400 MPa, a tensile strength of 230-550 MPa and an elongation of 15-45%.

Aesthetically pleasing:

Aluminum zinc plated steel sheet has a bright silver-gray surface with a regular zinc crystal pattern.

Advantages

Long service life:

AZ150 Galvalume is a highly coated aluminum-zinc coated steel, which will not corrode and perforate in 20-50 years under normal processing and service conditions.

Energy saving:

Uses galvalume GL steel as a building material, which reflects most of the infrared rays and reduces the indoor temperature.

Processability:

galvalume GL steel can be rolled, stamped, bent, painted, slit, and otherwise processed (Wanzhi Group offers these further processing services).

Cost Effective:

AZ150’s Aluminized Zinc coated steel has a lower long term cost of ownership, superior quality and cost effective pricing, making it an alternative metal solution to Z275 galvanized steel.

AZ150 Galvalume VS AZ 120 Galvalume

AZ150 AZ120 are two popular aluminized galvanized steel grades. Since the coating thickness of AZ150 Galvalume is higher than that of AZ120 Galvalume, the wear resistance, corrosion protection life, and high temperature stability of AZ150 Galvalume are better than that of AZ120 Galvalume.

| Parameter | AZ150 | AZ120 |

| Coating Mass | 150g/m² (both sides) | 120g/m² (both sides) |

| Single-Side Thickness | 10.5μm | 8.4μm |

| Salt Spray Life | 3000+ hours without red rust | 2000-2500 hours |

| Heat Resistance Limit | 480°C (short term) | 450°C (short term) |

| Bending Radius | ≥2t (t = sheet thickness) | ≥1.8t |

| Weldability | Requires Al-Si welding wire (ER4043) | Requires Al-Si welding wire |

| Surface Hardness | 90-110 HV | 85-105 HV |

Popular Galvalume Steel Grades + AZ150

The hot gate grades of AZ150 Galvalume are DX51D+AZ150, DC51D+AZ150, S350GD+AZ150, Q345B+AZ150, SGCC+AZ150, etc. DC51D+AZ150 is an alternative to DX51D+AZ150 for construction projects and non-load bearing scenarios. S350GD+AZ150 is stronger and suitable for load bearing structures.

- DX51D/DC51D+AZ150: Low carbon aluminum-zinc coating steel, yield ≥140MPa, tensile 270-350MPa, one of the popular materials for architectural roof/wall.

- S350GD/Q345B+AZ150: High-strength aluminum-zinc coating steel, yield ≥350MPa, tensile 420-550MPa, can be used as steel structure plant, purlin, etc.

- SGCC+AZ150: Japan standard low carbon aluminum-zinc coating steel, yield ≥140MPa, tensile 270-350MPa, better surface quality, often used as high-end architectural decoration and industrial components.

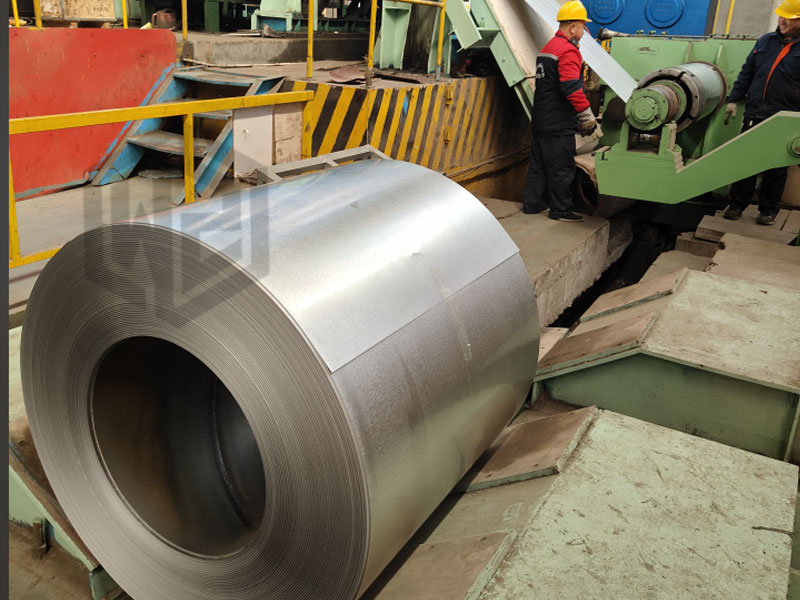

Galvalume AZ150 Factory

Galvalume AZ150 is one of the popular coated products produced by our factory, we have 1 production line for Aluminum-Zinc Coating and Zinc-Aluminum-Magnesium Coating, with an average production capacity of 10,000 tons per month, which can be customized in terms of thickness of coating, width of sheet, length, weight, surface structure, surface effect, paint coating and so on. Wanzhi Steel factory is located in Boxing County, Binzhou City, Shandong Province, China, and is ISO9001, ISO14001 certified. For factory tour or samples, please contact us.

Popular Products

Wanzhi Group’s popular aluminized zinc products are: galvalume steel coil, galvalume steel sheet, galvalume strip, galvalume corrugated sheet, galvalume ribbed sheet, galvalume stamped sheet, Painted galvalume steel, galvalume sandwich panel and so on.

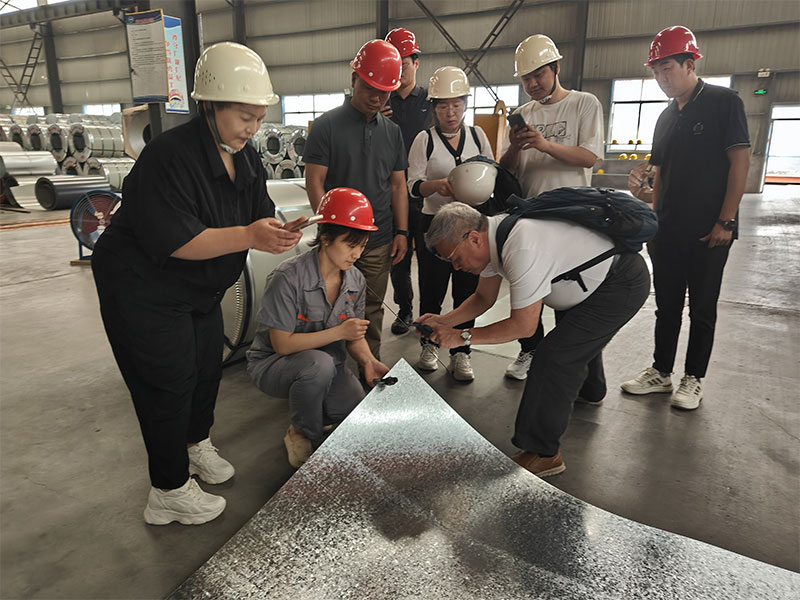

Factory Tour

So far, our factory has received customers from more than 40 countries and regions, and we have also opened an online tour where you can request a video tour of our zinc-plated factory wherever you are in the world.

Galvalume AZ150 Selection Guide

What substrate and finish of Galvalume AZ150 should be selected for different environments and projects in order to maximize the economic benefits? The Wanzhi Group has compiled a quick checklist of options for AZ150 GL steel, so take a look!

Applications

- C2 (dry countryside) 50 years +, can be replaced by galvanized Z120.

- C3 (urban/industrial) AZ 150 has a corrosion resistance of 25-50 years.

- C4 (coastal) environments AZ150 GL steel has a corrosion resistance of 15-25 years.

- C5 (highly corrosive industrial) environment with a corrosion resistance of 10-15 years, AZ150 + coating or stainless steel can be chosen as an alternative.

Application Scenario

- Building roof/exterior wall: DX51D+AZ150 galvalume, low cost and easy to process.

- Factory steel structure: S350GD + AZ150, high strength, good load bearing.

- New Energy: HX380LAD + AZ150, high strength, light weight.

Surface treatment

- Architectural/Industrial: ordinary aluminum zinc plated steel without surface treatment is sufficient.

- High-end construction: Painted aluminized zinc-plated steel with painted surface.

- Electronic plants: Aluminum zinc plated steel with conductive coating.

Supplier qualifications

- ISO 9001, ISO 14001, EN 10346/GB 2518 Warranty

- Aluminized zinc production line + production output

- Application examples + customer feedback

- Delivery deadlines

If you have questions about Galvalume AZ150 specifications, coatings, processing and solutions, leave us a message and let us know what you think!